High Voltage Frequency Drive 6.6KV 450KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

No need of extra output filtering device

Directly driving the general medium voltage synchronous or asynchronous motor and the temperature of the motor will not be increased.

No need of motor derating operation

No dv/dt damage to insulation of motor and cable

No torque ripple induced by harmonics, and the service life of motors and mechanism devices can be extended

No cable length limited when voltage drop is in the allowable range.

Besides the above advantages, medium voltage variable frequency drive has the following functions :

Protection of overload, overheat, over-current, open-phase, grounding, over-voltage, negative sequence.

Current limited function

Interlock protection of control power supply

Two sets of control power hot standby for redundancy

Power cell by-pass function

Control cabinet automatic bypass function

Cabinet door opening alarm function

Lock-phase function

Synchronizing switch function between variable frequency and power frequency (optional)

Soft start of motors, no impact to mechanical equipment and network

Voltage source High-high variable frequency drive, it can realize No-step speed regulation, which makes the typical motors into intelligent motors.

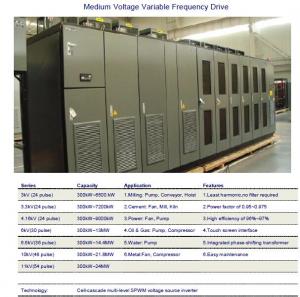

Medium voltage variable frequency drive has the following features:

- High quality power input: By phase shifting of the secondary winding and multi-pulse diode rectifier, isolated powers can be acquired and supplied for power cells. (18 pulses for 3/3.3kV, 30/36 pulses for 6/6.6kV, 48/54 pulses for 10/11kV) By using the technique of multi-pulse rectifier, the harmonic current could be eliminated greatly.

Power cell communicate with controller through optic-fiber, completely electric isolated

Inner set PID regulator, can realize running in closed-loop

Multiple communication methods with host computer, isolated RS485 interface, standard MODBUS RTU, communication protocol, PROFIBUS DP (optional), industrial Ethernet communication protocol (optional)

Accurately fault records, can inquiry information and locate fault

Compact construction, reasonable layout (can do customer-design)

Very good protective design to dust, ferrum pulveratum, acid mist, moisture etc.

Bypass cabinethas a function of "five-protection", meanwhile, it has a pressure relief channel to ensure the safety of operators.

Modularized design of power units, interchangeable and easy to produce and repair.

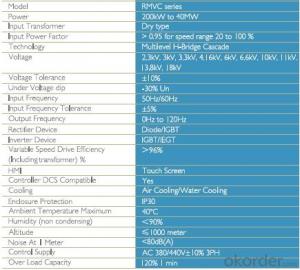

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: The inverter control power is also the same, the pole is not the same as the motor 6 or 4 pole can be used?

- Can be used, but is being used in the motor replacement, you need to change the frequency conversion.

- Q: What are the types of power adapter used in notebooks?

- Notebook function is limited, such as power requirements of only 50-70 watts (W). In recent years, power requirements have risen above 100 W, but the expectations for weight and size have not improved accordingly. In addition, the need to meet the low standby power performance in the specification, external power (EPS) efficiency requirements and IEC1000-3-2 harmonic power requirements above 75 W make this challenge more difficult to deal with. This article explores new trends that enable power supply manufacturers to address these challenges and provide alternative solutions to choose from.

- Q: What is the common COM point of the PLC and the inverter? Is it positive?

- It depends on your PLC and inverter I / O is what type, the most simple can be divided into two kinds of NPN and PNP, NPN COM point is negative, PNP COM is positive.

- Q: What is the working principle of high voltage electrodes and frequency converters?

- The general high and low methods are used in low-power high-voltage motor to do with energy-saving energy. Low-high-mode high-voltage inverter is controlled by a low-voltage inverter, the voltage directly to the motor with a step-up transformer voltage. Low-high mode is also used in low-power high-voltage motor to do with energy-saving energy.

- Q: Will the 75KW4 pole motor can be used to increase the speed of the inverter?

- China's power frequency 50hz, and the motor rated frequency match, blindly by increasing the frequency of the inverter output motor speed is not desirable, will affect the motor magnetic circuit, work is not normal.

- Q: Lenovo laptop power adapter side of the feet which is positive

- Very simple, look carefully on the power there is a symbol on the map (relatively small, carefully looking for all the regular power above the standard), as I shown below is the positive external, most of the power is like this , If the sign on the icon is anti, that is connected to the center of the black point is negative, that is negative inside the positive. This figure is also very intuitive.

- Q: Delta VFD-A frequency converter motor number of poles set

- According to the actual needs of the motor To provide the required power supply voltage, and then to achieve the purpose of energy saving, speed control, in addition, the inverter there are many protection features, such as overcurrent, overvoltage, overload protection and so on. With the continuous improvement of industrial automation, frequency conversion The device has also been very widely used.

- Q: HP laptop power adapter how to open

- Adapter is broken is difficult to repair, for a barThe common method is to insert the blade into the gap in the middle of the adapter and then pry open

- Q: 55 瓩 4 pole motor with a frequency of one hour can save much electricity

- It depends on what type of equipment you use, the average energy-saving fan pumps, about 25-40 between; generic class is based on the frequency you use to decide, according to the frequency you use with 50 Hz Compared to energy saving.

- Q: How to learn the inverter debugging and design parameters

- Personally think it is relatively simple, and now the inverter has been more intelligent, and some simple applications, and even do not need to set the parameters.

Send your message to us

High Voltage Frequency Drive 6.6KV 450KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords