Variable Frequency Drive 3.3KV 630KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM high Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Specifications

Variable Frequency Inverter

1.3KV ~11KV AC Driver Inverter

2.Suitable for motor speed regulation

3.Energy saving solutions

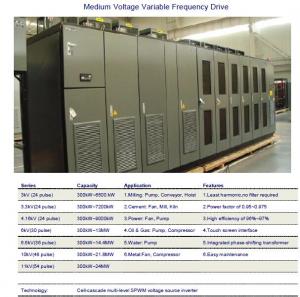

Specification and advantages :

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

5.The medium voltage circuits are linked with the controller by the optical fibers,which keep the controller safe and away from the disturbance.

6. The complete fault monitor circuit, accurate fault alarm and protection.

7. Integrated cooling blower

8. The control logic can be conveniently changed with the help of the integrated PLC.

9. Offer both field control and remote control in monitor station, providing convenient controlling options.

10. Support most of the industrial standard protocols (Profibus, Modbus, TCP/IP, etc.)

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: Laptop adapter

- The interface of the second adapter is the same as the first one And although the two numbers are not the same but the number of V on the line is the same as the interface

- Q: 65w adapter and 90w laptop power adapter What is the difference?

- 65W and 90W is mainly based on your laptop power configuration, the general integrated graphics with 65W, discrete graphics because of the need for additional power supply, so the general need 90W, of course, there are some low-power CPU, such as 25WCPU , 35W, 45W difference, these are the beginning of the manufacturer according to the notebook's power consumption count a maximum power, and then give your laptop with adapter 90W adapter can replace 65W, as long as the interface is the same, but 65W instead of 90W sometimes there may be insufficient power lead to automatic shutdown. In general, the greater the number of watts, the larger the head, because the adapter is actually a coil will be 220V into 19V, according to the power to determine the head, the larger the watt, the same 19V, then the output current will be greater

- Q: What is the difference between variable frequency motor and variable speed motor?

- Give you a formula, you can understand their speed control principle: N (speed) = 60f (frequency) divided by P (magnetic pole logarithm) According to the formula, when you want to change the motor speed, there are only two ways to change The number of pole pairs and the frequency of the power supply. Speed ??motor is variable pole speed, that is, in this motor has 2 to 3 sets of windings, by changing the winding connection, to change the motor pole to change the rotation speed.

- Q: Pump frequency converter instantaneous restart and restart the problem

- Inverter speed: Based on the advantages of speed control, energy saving and reliable operation, the frequency converter has gradually replaced the traditional variable speed, electromagnetic speed and voltage regulation. In the introduction of PWM flux vector control of the inverter a few years later, the end of 1998 and the emergence of DTC control technology inverter. ABB's ACS600 series is the first generation of DTC technology using the inverter, it can open the ring speed and torque for accurate control, and dynamic and static indicators have been better than PWM closed-loop control indicators. Direct torque control to measure motor current and DC voltage as input to the adaptive motor model. The model produces a set of precise torque and flux actual values ??every 25μs. The torque comparator and flux comparator compare the actual values ??of torque and flux with the reference values ??for torque and flux to Determine the optimal switch position. It can be seen that it is through the torque and magnetic flux measurement, instantly adjust the inverter circuit switching state, and then adjust the motor torque and magnetic flux, in order to achieve the purpose of precise control.

- Q: Will the motor suddenly stop when the inverter is suddenly powered down?

- but there are exceptions, such as head pump, water hammer effect after power failure will make the motor Reversal

- Q: Yasukawa inverter reported bb code that is the reason why the base blockade?

- This should be the meaning of the drive block, that is, the drive signal is locked, there is no drive signal, and start a frequency change but no voltage output, you find someone to repair the circuit board can be used normally, this is generally the circuit board Problem, the module is less likely to be bad

- Q: What are the AC motor speed control methods? What are the characteristics of each

- 1, the frequency converter: smooth, according to the need to adjust the speed, is the future direction of the development of AC motor; (FM) 2, star, triangular connection conversion, generally in the larger motor start star start, triangular operation, Starting current. (Magnetic pole pairs) 3, there is a two-speed, three-speed motor, an increase of the winding, the main change in the stator winding connection to change the speed. (Change the number of pole pairs) The speed of change has two factors: magnetic pole logarithm, frequency

- Q: Can the four motors be tuned to 2900 rpm?

- Will be affected, under normal circumstances overclocking is possible, but speed is not possible.

- Q: First reduce the frequency of about one-third of the test, not the case, then appropriate adjustments!

- In short, then connected to the bk-dk electrical appliances, is a resistor for the discharge effect

- Q: Quartet of the TA, TC terminals have positive and negative?

- There is no positive and negative, this is the relay output

Send your message to us

Variable Frequency Drive 3.3KV 630KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches