7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Brand:CHINSC

2.37kw variable frequency drive

3.MOQ:1 set

4.Best price and quality

5.Quick delivery time

Technical Specification

Item | Specification | |

Input | Rated voltage | T4 series: Three phase 380v, ±15% |

Frequency | 50/60Hz ±5% | |

Output | Voltage | Three phase 0-380V |

Frequency | 0-600Hz | |

Overload ability | Type G: 150% rated current for 1 minute, 180% rated current for 2 second; Type P: 120% rated current for 1 minute, 150% rated current for 2 second. | |

Heat Dissipation | Cooling type | Forced Cooling |

Temperature protection | Heatsink temperature >85degree trip protection against overheat | |

Fan control | Heatsink temperature> 50degree, fan forced operation, frequency inverter continue work | |

Control Performance | Control mode | Open-loop vector control, V/F control, Torque Control |

Start torque | Open-loop vector control: 0.5Hz 180%; VF control:0.5Hz 150% | |

Speed range | Open-loop vector control: 1:200; VF control:1:100 | |

Speed control precision | Open-loop vector control: ±0.2%; VF control:±0.5% | |

Torque control precision | Open-loop vector control: ±5% | |

Torque response time | Open-loop vector control: <20ms< span=""> | |

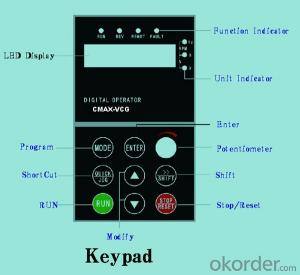

Function | Channel of operation command | Keyboard control,terminal control,communication control |

Start mode | Direct start, DC injection braking before start, speed tracking before start | |

DC injection braking | Start DC injection braking, stop DC injection braking | |

Dynamic braking | Built-in braking unit < = 11kw, get external braking unit>15kw | |

Frequency source choice | Keyboard digital frequency setting, analog V1 setting, analog V2 setting, Keyboard potentiometers setting, Multiple speed operation setting, PID control setting, telecommunications setting, PLC program operation setting, HDI High Speed Pulse setting | |

Main and auxiliary frequency combination set | Just main frequency setting, just auxiliary frequency setting, QUICK/JOG or terminal switching selection, main frequency + auxiliary frequency, main frequency - auxiliary frequency, maximum, minimum, could realize Frequency overlay and fine adjustment function | |

Frequency resolution | Keypad setting:0.01Hz; Analog setting: 0.1% | |

Carrier frequency | 0.5Khz~15.0Khz, both PWM mode could be chosen | |

Acc/Dec time | 0.1~3600.0s | |

Multiple VF curve | Linear V/F curve, 2.0 times power drop torque V/F curve, custom V/F percentage (can realize manual energy saving control), multipoint VF curve. | |

Built-in PID | Built-in PID controller, apply to process control occasion such as water or gas supply. Meanwhile the sleep wake up function could save energy to the great extent possible. | |

Simple PLC operation | 16 segment goal setting, frequency or mode of percentage setting could be chosen, each segment of operation time and direction could be set separately, and realize timing stop function. | |

Common function | Speed tracking, Cut-off restart, fault recovery, Automatic torque promotion, the motor’s parameters auto-learning, Pendulum frequency operation, hopping frequency, UP/DOWN control, AVR, Over-voltage stalling protection, rapid current-limiting, Instant power down and drop frequency operation | |

Input Output Signal | Analog input | V1:0~10V V2:4~20mA or 0~10V, Select through JP2 jumper Keyboard potentiometer input: 0~5V |

Analog output | FM1:0~10V or 0~20mA, Select through JP9 jumper FM2:0~10V or 0~20mA, Select through JP10 jumper. Need the support of SC-EXT1-IO expansion cards | |

Digital input | Standard configuration S1~S6, can expand S7~S10 through SC-EXT3-S expansion cards. A total of 30 kinds of function could be selected. | |

Digital output | Standard configuration 2 channel including SP1, SP2 electrode output; 1 channel relay output T1; Expanding 4 channel relay output T2~T5 through SC-EXT2-R expansion cards. | |

High-speed pulse input | HDI: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

High-speed pulse output | HDO: 0~50.0Khz, support by expansion cards SC-EXT1-IO | |

Communication Port | Communication protocol | Based on RS485 hardware, support standard MODBUS protocol, should match expansion cards SC-EXT1-IO |

Expansion Cards | 3 type expansion cards | Standard expansion cards SC-EXT1-IO, Relay expansion cards SC-EXT2-R (can realize one drives 2 function), Multifunctional input expansion card SC-EXT3-S, refer to the explanation in Appendix. |

Display Functions | Five digital tube display | Can monitor the operation state of frequency inverter flexibly and conveniently; can set normal monitoring parameters separately when operation and stop. |

Protection Function | 25 kinds of protection functions | Including over-voltage, over-current, overheat, overload, under-voltage, short circuit, ground fault, input and output default phase, protect the frequency inverter running reliably all-round. |

Installation Environment Requirement | Ambient temperature | -10degree~+40degree(ambient temperature is within 40degree~50degree, derating use is required), not allow to contact direct sunlight. |

Humidity | Less than 90%RH, without condensation | |

Application environment | Non-corrosive, flammable, explosive, dust absorbent material, all kinds of lint does not accumulate. | |

Vibration | Less than0.6G | |

Elevation | 0~1000m, reduce the rated specification 10% when lift 1000m for each. | |

Storage temperature | -20~60degree | |

Factory Overview

Application

Textiles, Plastics, Ceramics, Electronics, Numerical Controls, Foods Processing, Light Industry, And Pharmaceuticals. Oil, mining and other fields.

Certification

Welcome your inquiry!

Looking forward to cooperating with you!

- Q: Can different brands of laptop power adapters be generic?

- Power adapter can not use, the key to see two factors. First, the interface must first be the same interface or can not use. Second, the output current, the output current must be strictly consistent, otherwise it would be very dangerous, the laptop overload of the current is very fragile. The final output voltage I personally think can have a difference of type 5V. Because the battery on the voltage requirements up and down can have 5V floating. I have also used a high 5V adapter, has been no problem, but this is just my personal view. Strictly the same as the best. Oh, for reference only! Since you can plug in the normal use, indicating that the interface is consistent, and the output voltage and current are the same. Then I can responsibly tell you, rest assured to use it, there will be no problem.

- Q: My inverter is the era TVF8000 series, the motor is 15KW6 pole motor, has been used for 3 years.

- If the frequency converter is selected according to the motor rated current, then the motor current exceeds the rated current, the inverter will become overcurrent protection In this case, that is, when the inverter began to select the amount of time to stay the lack of the same power, inverter general type than the fan pump type current capacity of a high grade If the inverter selection is no problem, then please see whether the inverter is working temperature is too high, too high will cause the electronic components to resist the decline in current. First, check the inverter to work the ambient temperature, the second Please check the inverter fan is damaged, clean down the inverter fan channel and fan to see if there is no plug

- Q: How to disassemble the notebook power adapter

- 3, then open the shell of the power adapter, you can see the adapter circuit outside the package with a copper shield, with a knife to cut the shielding tape on the tape, and then use the soldering iron shield and the internal circuit board connected to the two Solder joints, you can remove the shield.

- Q: Master Hello a machine requires 500 speed matching 6-pole motor frequency converter transferred to about 28HZ

- If the machine needs the same speed, constant 500r / min This can be directly with the motor, remove the inverter, but also save costs, while the motor at 50Hz, the maximum power point of rated power. Output torque is the most stable point. The pulley diameter becomes smaller and the reduction ratio increases, and the torque required by the motor becomes smaller, which is advantageous for the motor. 960/500 = 1.92, that is to say the motor pulley compared to the original tune less 1.92 times

- Q: Is the motor having a variable frequency motor and a variable voltage motor?

- According to the way to start talking about a variable frequency motor and variable voltage motor

- Q: How to choose a Siemens inverter for a 5.5KW three-phase motor (2 pole)?

- Siemens frequency conversion dedicated input / output filter, reactor, you contact us but smell it, the quality is guaranteed. We look forward to cooperation.

- Q: Taian inverter 3.7KW 380V with 4.0KW 2 pole motor 18000 to 300HZ can it?

- With green wave Jie can experience to judge, there may be two possibilities: First, the inverter power selected small. Bipolar motor, not a four-pole motor, the inverter is designed according to the four-pole motor model, so in the inverter selection, can not only look at the power, but also the rated current of the motor;

- Q: Variable frequency conversion frequency difference characteristics based on,

- Frequency conversion is better, you can smoothly change the synchronous speed. Change the difference is relatively poor, also known as "energy consumption slip" speed. Synchronous speed unchanged, the slip rate has changed, so the speed changed.

- Q: Please recommend a high performance laptop power adapter?

- Power adapter can recommend you what model you get what model ah he is a standard can not just recommend

- Q: Quartet of the TA, TC terminals have positive and negative?

- There is no positive and negative, this is the relay output

Send your message to us

7.5kw 380v 3 phase variable frequency drive ac motor controller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches