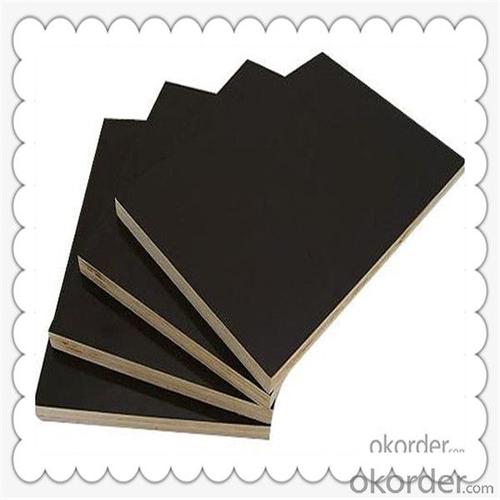

Film Faced Plywood with High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

· Type: Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Particle Board

· Use: Indoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Sandwich board glue where the good

- There are too many types of glue can not be unified If it is on the market of ordinary glue, its composition is basically water, add some polyvinyl alcohol, white latex, sodium stearate, talc, urea, ethylene glycol, sucrose, flavor, etc., little harm to the human body (if Used to eat), if used when the eye drops with the estimated consequences are more serious. 502 glue is the main component of α-cyanoacrylate, its essence is colorless and transparent, low viscosity, non-combustible liquid, a single component, no solvent, slightly stimulating taste, volatile, volatile gas with weak tear The Building adhesive, 707 emulsion and other high-level additives, the current commonly used 108 plastic main component of polyvinyl alcohol Scope This product is suitable for concrete, aerated concrete, lime sand brick, fly ash brick interface treatment, can also be used for plastering mortar, paste the tile sand ash additives to enhance the adhesive force.

- Q: The current market price is how much money a square meter?

- Color plate, foam core, safe, durable, beautiful. Shelf life of more than 10 years. Color steel plate prices to see the thickness of the GB of 02,0.4,0.6,0.8, non-GB of the more, 0.3,0.5,0.35,0.45 have, you'd better ask the price in the local, around the price of different ah, Plus the freight of what, it is difficult to cost.

- Q: OKorder Caigang sandwich panels, foam sandwich panels, manufacturers production? Price concessions

- OKorder Tengwei color steel limited is a professional market Caigang sandwich panels, rock wool color steel sandwich panels, paper honeycomb sandwich panels, polyurethane color steel plate, extruded Caigang sandwich panels, color steel pressure tile, aluminum Tile, C / Z-based professional steel manufacturers. The company's products have been widely used in large workshop plant, workers dormitory, site plant, office space, activities, cold storage, supermarkets, hospitals, clean room and the need for insulation compartment. OKorder Teng Wei color steel, ten years to build, because the professional, so trust!

- Q: Is the foam sandwich plate formaldehyde?

- Use to enjoy the formaldehyde detector under the test to know whether it contains formaldehyde, and large screen real-time display, triple alarm preset function, Portable compact hand.

- Q: What is the ESP sandwich panel

- EPS is polystyrene, which is what we call foam board Sandwich refers to the foam as the core material, the external double-sided composite material of other plates. Other plate is generally the majority of color steel plate.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- Color steel sandwich panel thickness from 0.25-0.8 can be customized Detailed price can consult OKorder to enjoy color steel structure Co., Ltd. 021-39105864 This is a professional production and processing Caigang sandwich panel Caigang tile manufacturers

- Q: How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

- Q: what is the specification of Alumni foil used in the sandwich panel(foam) as roofing?

- Alumni do not make good foil material........

- Q: Sandwich board is used to do what ah ??

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

Send your message to us

Film Faced Plywood with High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords