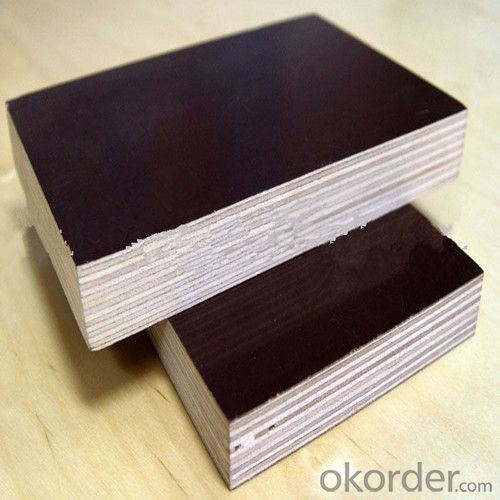

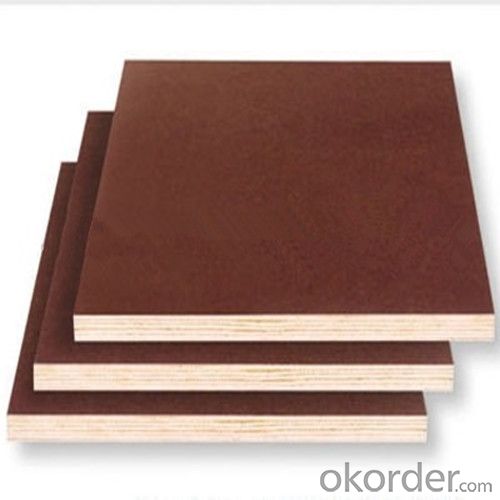

Brown and Black Film Faced Plywood for Outdoor Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: film face

· Color: Brown & Black

Packaging & Delivery:

Packaging Details: 1) Covered with box paper, the tied in steel tape, then put one pallet under bundle. 2) Loose packing in the container.

Delivery Detail: 20 days after receive the advance payment.

Specifications:

Brown and Black Film Faced Plywood:

Size:1220x244, 1250x2500.

Material: Poplar, Birch, Hardwood, Combi Core.

Glue: MR, Melamine, WBP.

Brown and Black Film Faced Plywood:

1) Material: Poplar, Birch, Hardwood, Combi Core.

2) Color: Black and Brown.

3) Glue: MR, Melamine, WBP.

4) Size:1220x2440, 1250x2500.

5) Thickness: 9mm, 12mm, 15mm, 18mm.21mm

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Can sandwich panels take home in the bathroom? Rural use ,,, long time will not rot

- Sandwich board is wood, up to 2, 3 years will begin to rot, just answer that is the aluminum-plastic plate, aluminum-plastic plate more expensive slightly, with aluminum and glass do not expensive, beautiful, more rural The

- Q: Pressure plate composite insulation board and the difference between the sandwich panels, the price difference is large? What kind of geng good for steel structure plant design?

- The top of the plant with sandwich panels

- Q: How is the ceiling of the residential sandwich panel under the roof?

- Method is to use the form of flat ceiling, the top of the pipeline blocked in the ceiling, the top can be embedded in the downlight or built-in fluorescent lamp, so that the top of the decoration after the formation of two levels, will not produce a sense of depression. Shaped ceiling with a cloud-like wave or irregular arc, generally not more than one-third of the overall top area, more or less than this ratio, it is difficult to achieve good results.

- Q: Sandwich board machine how much money

- I am the production of color plate machine, and hope to cooperate with you, OKorder Zhongji machinery Yang Yun

- Q: in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q: what is the specification of Alumni foil used in the sandwich panel(foam) as roofing?

- Alumni do not make good foil material........

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Are thermocol roof insulation boards or thermocole sandwich concrete bricks durable?

- I typed in thermocol and this is what it gave me. Hope it helps. polystyrene (p?l'ēstī`rēn), widely used plastic plastic, any organic material with the ability to flow into a desired shape when heat and pressure are applied to it and to retain the shape when they are withdrawn. Polystyrene is a colorless, transparent thermoplastic that softens slightly above 100°C; (212°F;) and becomes a viscous liquid at around 185°C; (365°F;). It is resistant to acids, alkalies, oils, and alcohols. It is produced either as a solid or as a foamed plastic marketed under the trade name Styrofoam. Its many uses include electrical and thermal insulation, translucent window panels, storage-battery cases, and toilet articles

- Q: Color steel sandwich panel can do the widest, can be more than rice

- The effective width of the color steel sandwich panel is based on the shape of the steel plate you choose. The surface of the sandwich panel has a flat plate and a few peaks, such as: 1) The surface is flat so that its effective width can reach 1.16 m The maximum width of the steel plate is 1.2 m due to the sandwich panel edge structure in order to increase the compressive strength to be folded 2 cm) 2) the surface is a wave shape of the steel plate that you should choose the peak size and size to calculate its maximum effective width.

- Q: Ultrasonic cleaning machine cleaning Caigang sandwich panels the most basic quality conditions?

- The advantages of more professional cleaning machine work in the practice of the pursuit of a higher level of progress and development, improve the actual production efficiency of the guarantee, the most important thing is to really clean the product to achieve better cleaning results, to ensure greater advantages Cleaning conditions to achieve the purpose of cleaning, cleaning rate is the most important high-quality assurance.

Send your message to us

Brown and Black Film Faced Plywood for Outdoor Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords