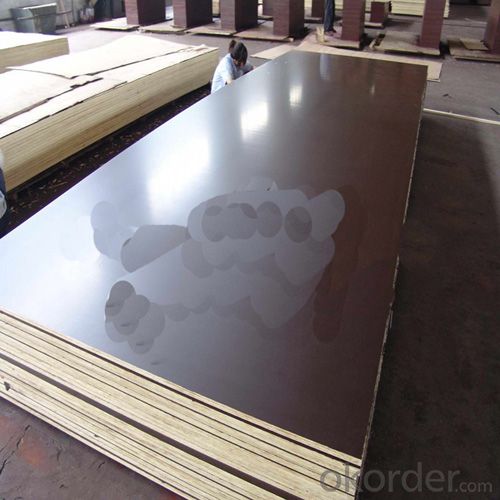

18mm Thickness Waterproof Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: P-001

· Usage: Outdoor, Indoor,Furniture, construction, packing

· Grade: First-Class

· Main Material: Poplar, hardwood/Poplar/eucalypts/pine/birch

· Formaldehyde Emission Standards: E1

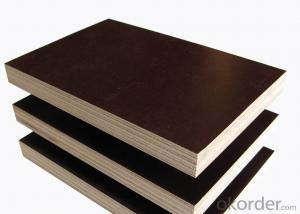

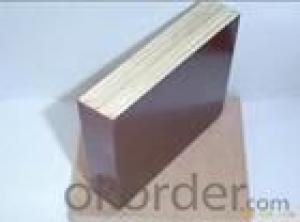

· Plywood Type: 18-Ply Boards, 3,4,5,7,9,11,13,15,17,19 Ply boards etc

· Core: Poplar, Hardwood, Combi, Birch, eucalypts

· Size: 1220X2440mm/1250X2500mm

· Thickness: 2.0mm~30mm

· Density: 500-750 kg/m³

· Glue: E0,E1,E2,MR,melamine,WBP

· Certification: ISO9001: 2008; CE; CARB

Packaging & Delivery:

Packaging Details: | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength |

Delivery Detail: | 2 weeks after your deposit |

Film Faced Plywood :

1.ISO9001:2008;CE;CARB

2.Face/Back: Black/brown/red/anti-slip film

3.Glue:E0,E1,E2,MR

4.Size:1220*2440/1250*2500mm

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Polyurethane sandwich panels polystyrene sandwich panels how to identify? 75 models Price / square?

- Very good to distinguish, there is particles is polystyrene.

- Q: V950 color steel rock wool sandwich panel and v960 color steel rock wool sandwich board what does it mean

- Is the practical width of the tile of 950 watts a meter long is 0.95 level 960 is 0.96 level

- Q: Domestic manufacturers of rock wool sandwich panel machine which quality is better? What is the price in general?

- My company is using OKorder Yongming, spent more than six years. I personally feel that quality can be. My friend is using the other manufacturers in OKorder, you can also use, the domestic manufacturers in OKorder is doing a little better. As for the price, a price of a cargo, the landlord can visit more, the domestic production of such equipment manufacturers concentrated in OKorder and Hebei.

- Q: Bubble (EPS) color steel sandwich panels how to wear thread

- EPS sheet can not use the dark cable way, you must use PVC flame retardant pipe cable, need to use the hole at the hole, out to look good.

- Q: What is the difference between a rock wool sandwich panel, an EPS sandwich panel and a polyurethane sandwich panel?

- 1, different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. 2, different insulation properties: the three polyurethane sandwich panels the best. 3, waterproof performance is different: the three polyurethane and EPS better than rock wool. 4, the density is different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally 16, polyurethane is generally 40. All in all, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure enclosure!

- Q: How to choose the type of steel structure plant roof sandwich panels

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. ???? Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. ???? Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- This is a tough one. You may have to use 2X4's to extend the wall inwards to allow for it. I attached a link that might help.

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Do you need to make a flat beam or a triangle? Made flat can use H-beam, do the triangle can be used C-shaped double-fight. Depends on your specific requirements.

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of tile it?

- I only know that the glass beads can be made tiles

Send your message to us

18mm Thickness Waterproof Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords