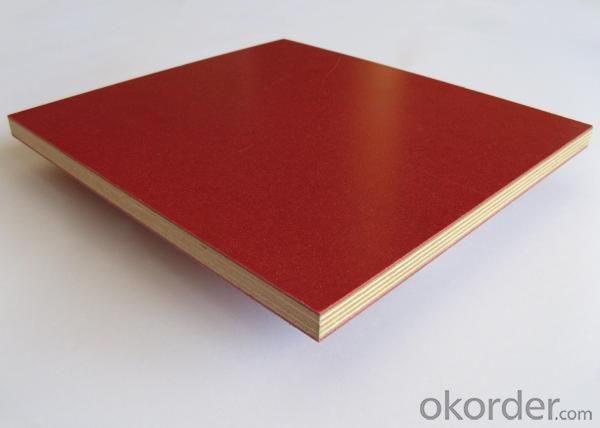

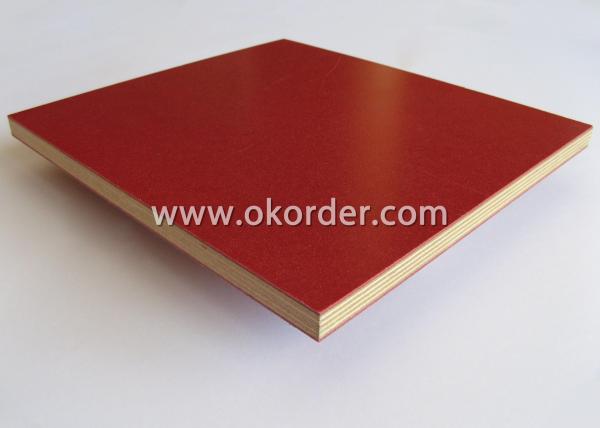

HDO Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of HDO Plywood

High density overlaid plywood forming panels have greater dimensional stability and smoother, more durable forming surfaces than

nonoverlaid panels. If you want the smoothest possible concrete finish and a high number of form reuses, choose HDO panels.

Their hard, abrasion-resistant surfaces produce a glossy finish, and with reasonable care the panels provide 20 to 50 reuses.

Some concrete forming specialists can achieve up to 200 reuses with careful maintenance of the forms

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications of HDO Plywood

1220 mm×2440 mm,1250 mm×2500 mm, including other special sizes.

2)Thickness:4-40mm, which is allowed to be adjusted by the customers’ requests accordingly

3)Core:poplar birch combi

4)Glue: WBP, phenolic

5)OVERLAY Surface: imported film 320g/m2

6)Package:Seaworthy packing

7)Usages:can be widely used in construction, furniture decoration, etc.

Advantage of HDO Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Fibreboard: According to bulk density is divided into hard fiber board, semi-rigid fiberboard and soft fiber board 3 kinds. Hard fiber board is mainly used for the ceiling,

- Q: Selection of plywood in plywood production

- In the production of plywood, derived from a lot of color varieties, one of the most important one is in the original plywood board surface affixed with a thin layer of decorative veneer, known as decorative veneer veneer plywood, the market referred to as decoration Board or trim panel.

- Q: How do you choose plywood in plywood production?

- but the overall furniture, wood is made of other wood, and now the store will be the furniture as "

- Q: How is the current market outlook for plywood?

- to achieve cumulative product sales of 96,534,099 thousand yuan, an increase of 48.87% over the previous year

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: Multilayer plywood with what method is fixed

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like materia

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

Send your message to us

HDO Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords