Marine Plywood for Construction & Building Construction Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: P-001

· Usage: Outdoor, Indoor,Furniture, construction, packing

· Grade: First-Class

· Main Material: Poplar, hardwood/Poplar/eucalypts/pine/birch

· Formaldehyde Emission Standards: E1

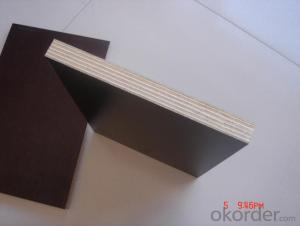

· Plywood Type: 18-Ply Boards, 3,4,5,7,9,11,13,15,17,19 Ply boards etc

· Core: Poplar, Hardwood, Combi, Birch, eucalypts

· Size: 1220X2440mm/1250X2500mm

· Thickness: 2.0mm~30mm

· Density: 500-750 kg/m³

· Glue: E0,E1,E2,MR,melamine,WBP

· Certification: ISO9001: 2008; CE; CARB

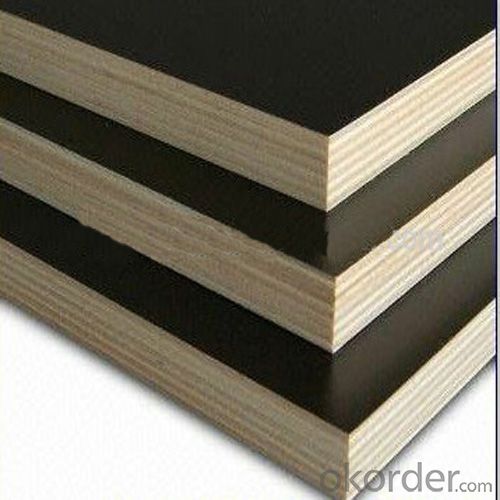

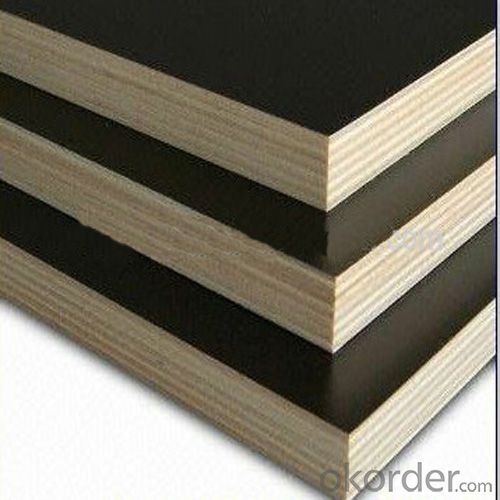

Film Faced Plywood:

1.ISO9001:2008;CE;CARB

2.Face/Back: Black/brown/red/anti-slip film

3.Glue:E0,E1,E2,MR

4.Size:1220*2440/1250*2500mm

Detailed Product Description | ||

Place of origin | Shandong China | |

Face&back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested | |

Core | Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement. | |

Size | 1220*2440/1250*2500mm and as your requirement | |

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) |

1/4 inch(6-6.5mm) | ||

1/2 inch(12-12.7mm) | ||

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 2-6mm: +/-0.2mm | |

6-30mm: +/-0.3mm | ||

Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | |

Glue | MR,E1,E2,Melamine,WBP Phenolic | |

Moisture | 10%-15% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction, Furniture, decoration, packing. | |

Certificate | ISO9001: 2000; CE; CARB | |

Main market | Middle East, South Asia, South America, Africa | |

Shipment & payment | ||

MOQ | One container | |

Port | Qingdao | |

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | |

Delivery time | 2 weeks after your deposit | |

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | |

Advantage | ||

Capacity: 6000 CBM per month | ||

Sample available | ||

high quality and competitive price | ||

30 years’ experiences in export | ||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Level sandwich panels are not 820 type

- In fact this is nothing, JXB is not the first letter of the word sandwich panels. 42-333-1000 This is the sandwich panel on the upper and lower color plate model. For example: YX28-205-820 pressure wave height of 28MM wave width 205MM effective width is 820mm a look at this model is 4 wave color plate JXB42-333-1000 can explain: sandwich board which up and down a plate of the color plate 42MM pitch 333 effective use of the width of 1000 This model can be seen is 3 wave pressure plate. Sandwich panels are made of upper and lower color plate glue (foam) combination. The composition of the bubble is different, the name is also different, there are rock wool with polyurethane and so on

- Q: Can Caoyan sandwich wall be installed? How to install Thank you

- Take a look at the drawing

- Q: Roof 100mmEPS sandwich board how much money a square

- Color plate thickness, EPS density you have to clear it in order to get the exact price. More than 60 in Shenyang are more than 100 are possible, depending on the specific quality requirements.

- Q: I've been on a diet for a week now and because of my new low calorie food i eat it's a struggle to even get to 1200 calories by the end of the day! I've been eating 3 sandwiches a day. They consist of whole wheat bread, one slice of ham, and one slice of cheese each. But i'm afraid eating six slices of whole wheat bread will make me gain weight even if I am eating them for the calories to get to at least 1200. Should I stop or is this alright?

- That all depends! It can be bad in the long run if you aren't getting balanced nutrients from the sandwiches. With just ham and cheese, there's no way you could be getting everything your body needs nutritionally! Try adding variety into your sandwiches using lettuce, tomatoes, different meats, different dressings, new veggies, etc. Of course, this doesn't mean to go overboard with any one ingredient - keep it healthy. And remember, don't always use fat free dressings; a lot of the time, when there are other veggies involved, they are best consumed with a healthy fat source for best absorption. Regarding the bread... whole wheat bread isn't always what it seems. Real whole wheat bread is made from real whole grains, and you must check the ingredient panel to ensure this is what you are eating; there has been a bit of trickery in the bread industry. The first ingredients should contain items such as whole wheat flour, 100% rolled oats, whole grain corn, etc. Any enriched flour, even if whole wheat, is not what you're after. Sandwiches can be great as long as they are balanced nutrition-wise, so if you really like 'em, I wouldn't say they are a problem. Just make sure your caloric intake is correct for your daily needs, and that you're getting some variety.

- Q: Sandwich board is how the synthesis

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

- Q: 50mm thick insulation color steel sandwich board with J * B42-333 * 1000 What does this mean?

- It may be said that the sandwich board wave height 42 wave width 333 width 1000 bar Oh country mark should not be so that the specification model

- Q: Sandwich panel prices, and specifications

- Y-2100 intelligent polystyrene sandwich board vertical production line, is our company according to the relevant requirements of the market for the bold design of their own innovative manufacturing in line with the "building partition with light strip" JG / T169-2005 standard production line self Equipment, size and cross-section size, product specifications in line with national recommended series. The production line will be divided into the storage process system, polystyrene particle grammar system, automatic feeding system, sandwich material mixing system, forming plate machine, casting system, mold recycling system, a product casting molding, the production of calcium silicate cement fiber pressure Plate pallet heart panel. A board machine production line can achieve the class output 600-800 square meters of finished products, automatic control of the production process, each production line required artificial 4-6 people.

- Q: Can Caigang sandwich panels cover cottage? Is it possible to install it?

- Can, need color steel sandwich panels to find Wujiang City, the LEADER air conditioning purification equipment engaged in color steel technology research and production, sales manufacturers

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

- Q: What are the requirements for the use of foam sandwich panels for fireworks

- Roof absolutely do not use, the wall can discuss to reach the fire rating

Send your message to us

Marine Plywood for Construction & Building Construction Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords