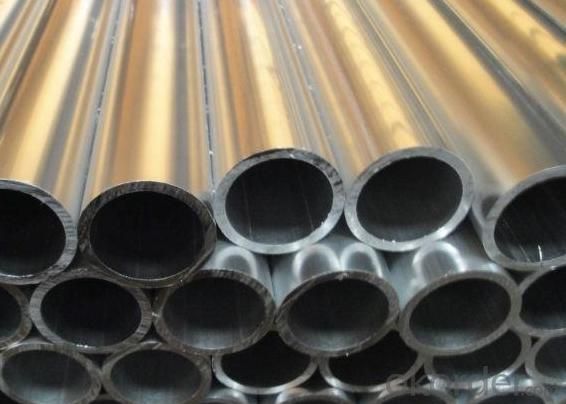

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 1060:

1.Specifications of aluminium pipe 1060:

1)Alloy:1060;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

2.Application of aluminium pipe 1060:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 1060:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: What heat transfer materials, such as metals, copper tubes, aluminium tubes, and glass tubes, can transmit heat more quickly, and I would like to ask what else can be used as heat conducting materials, which are resistant to heat and relatively strong. Good thermal conductivity. What else can I do besides metal?

- In addition to metal, high temperature resistance, heat transfer is good for most quartz, graphite, three, two aluminum oxide, zirconia, etc., more common 1000 degrees above heaters, crucibles, etc., are mostly made of these materials. I don't know exactly what you're for.

- Q: The length of the aluminum tube is about 180mm, the diameter is 19mm, and the wall thickness is about 1mm. It should be bent into the radian of R300. No deformation

- Pouring sand into the aluminum tube, the two ends are blocked and then the bend will not deformWith lead? Where do you go for lead?

- Q: How to repair the surface defects of aluminum pipe

- Third, the pipe is used to do it, the thickness of a pipe length measurement and recording, in general use will be selected according to the use of its wall thickness specifications and the length of the specifications, if found to have stiff head tubes should be timely marked when used to head to stiff it uses the slow speed, and high temperature.Fourth, after the completion of the expansion pipe, aluminum pipe to the appearance check to see whether the pipe surface defects, if flawed, allowing him to eliminate the timely elimination of defects if too much, not to be able to restore to enter the furnace re grinding clean.When the fifth tubes are heated, the thickness of the top three branch material shall be measured. After the expansion is completed, a measurement shall be carried out, and the expansion speed and temperature shall be adjusted according to the changes of these two measurements.The whole round repair of aluminum tubes is the most common repair in the industry, with the following methods for repairing the pits or flattening

- Q: Which pressure is high between titanium tube and aluminium tube?

- It depends on how to compare, pure titanium tube or titanium alloy tube? Pure aluminum tube or aluminium alloy tube? Titanium alloys and aluminium alloys are divided into many grades.

- Q: What is the difference between air conditioning copper tubes and aluminum tubes?

- The copper tube has high heat transfer efficiency, corrosion resistance and good strength, but the price is expensive.The heat transfer efficiency of aluminum pipe is higher, the corrosion resistance is not good, but the price is much cheaper.

- Q: Are aluminum pipes suitable for potable water tanks?

- Yes, aluminum pipes are suitable for potable water tanks. Aluminum is a corrosion-resistant and lightweight material that does not leach harmful substances into the water, making it a safe and reliable choice for potable water storage.

- Q: Are aluminum pipes suitable for pulp and paper processing?

- Yes, aluminum pipes are suitable for pulp and paper processing. Aluminum is a corrosion-resistant material that can withstand the harsh chemicals and conditions commonly found in the pulp and paper industry. It is also lightweight, making it easier to handle and install. Additionally, aluminum pipes offer good thermal conductivity, ensuring efficient heat transfer in various processing applications.

- Q: Which friend has the national standard about seamless copper tube and aluminium tube, some help to send, very grateful, urgent!

- National standard for seamless aluminium tubesnominal outside diameterOrdinary (+)High precision (+)Any outside diameter a and nominalAllowable deviation of outside diameterAllowable deviation of average outside diameter B and nominal outer diameterAny outside diameter a and nominalAllowable deviation of outside diameterAllowable deviation of average outside diameter B and nominal outer diameterAnnealing tube5083 CQuenchOtherAll tubesAnnealing tubeQuench tubeOtherAll tubes> 120 to 150Two point two eightZero point six threeZero point seven sevenZero point three eightZero point three eightOne point five zeroZero point five zeroZero point two fiveZero point two five> 150 to 180Three point four fourZero point nine fiveOne point one fourZero point five sevenZero point five sevenTwo point two fiveZero point seven sixZero point three eightZero point three eight> 180 to 220Four point five eightOne point two fiveOne point five threeZero point seven sevenZero point seven sevenThreeOneZero point five zeroZero point five zeroA any outer diameter refers to the outside diameter measured at the point at the pipe section.The mean od of B refers to the average value obtained by measuring the total diameter of two arbitrary angles at the cross section of the pipe.When the C 5083 alloy tube is annealed, the deviation is performed by the annealing tube.[amendment to the national standard 2012-06-14 14:45] seamless copper tube

- Q: What is the typical wall thickness of aluminum pipes?

- The typical wall thickness of aluminum pipes can vary depending on the specific application and industry requirements. However, common wall thicknesses for aluminum pipes range from 0.065 inches to 0.250 inches.

- Q: Can aluminum pipes be used for irrigation sprinkler systems?

- Yes, aluminum pipes can be used for irrigation sprinkler systems. Aluminum pipes are lightweight, durable, and resistant to corrosion, making them suitable for use in irrigation systems. Additionally, they are easy to install and maintain, making them a popular choice for many agricultural and landscaping applications.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords