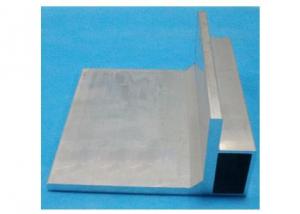

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different fastening options available for aluminum profiles?

- There are several different fastening options available for aluminum profiles, depending on the specific application and desired functionality. Some common fastening options include: 1. Screws: Using screws is a widely used method to fasten aluminum profiles. They can be easily installed and provide a strong and secure connection. Self-tapping screws are often used, as they create their own threads in the aluminum profile. 2. Bolts and nuts: Bolts and nuts offer another reliable fastening option for aluminum profiles. They provide a strong connection and can be easily tightened or loosened as needed. It is important to select the appropriate bolt and nut size and ensure proper tightening to prevent stripping or loosening of the connection. 3. T-slot nuts: T-slot nuts are designed specifically for T-slot aluminum profiles, which have a groove along the length of the profile. T-slot nuts slide into the groove and can be easily positioned and tightened using a hex key. They provide a versatile and adjustable fastening option, allowing for easy repositioning or modification of the profile. 4. Clamps: Clamps are commonly used to secure aluminum profiles together or attach other components to the profile. They come in various designs, such as corner clamps or angle clamps, and provide a quick and easy way to assemble or disassemble aluminum structures. 5. Adhesives: Adhesives can be used to bond aluminum profiles together, offering a clean and seamless appearance. However, the strength of the bond may vary depending on the adhesive used and the surface preparation. It is essential to select an adhesive specifically designed for aluminum and follow the manufacturer's instructions for proper application. 6. Welding: Welding is a permanent fastening option for aluminum profiles. It involves melting the aluminum material and fusing it together, creating a strong and durable connection. However, welding requires specialized equipment and skills, making it a more complex and time-consuming process. It is important to consider the specific requirements of the application, such as load-bearing capacity, adjustability, or disassembly needs, when choosing the appropriate fastening option for aluminum profiles. Consulting with experts or manufacturers can help in selecting the most suitable fastening method for a particular project.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be used in curtain wall systems. Curtain wall systems are typically made of lightweight materials that provide structural support while allowing maximum natural light into a building. Aluminum is a popular choice for curtain wall systems due to its strength, durability, and versatility. It offers excellent resistance to corrosion, making it suitable for outdoor applications. Additionally, aluminum profiles can be easily fabricated into various shapes and sizes, allowing for flexibility in design and assembly. The lightweight nature of aluminum also makes installation easier and more cost-effective. Overall, aluminum profiles provide an ideal solution for curtain wall systems, delivering both aesthetic appeal and functional performance.

- Q: How do aluminum profiles compare to plastic profiles?

- Aluminum profiles generally offer greater strength, durability, and stability compared to plastic profiles. They can withstand higher loads and have higher resistance to heat, chemicals, and UV radiation. Additionally, aluminum profiles provide more design flexibility, as they can be easily machined, welded, and anodized to achieve desired shapes and finishes. However, plastic profiles are often more cost-effective and lighter in weight, making them suitable for certain applications where strength and rigidity are not critical. Ultimately, the choice between aluminum and plastic profiles depends on the specific requirements and constraints of the project.

- Q: Industrial aluminum profiles are generally used in what industry?

- Kunshan Austrian crown aluminum to tell you: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.

- Q: Is it feasible to recycle aluminum profiles economically and in significant quantities?

- <p>Yes, aluminum profiles can be recycled at a reasonable cost and volume. Recycling aluminum is more cost-effective than mining and refining new aluminum from bauxite. The process requires less energy, which reduces costs. Additionally, aluminum has a high recycling rate, with about 75% of all aluminum ever produced still in use today. This indicates that aluminum recycling is both economically viable and can be done in significant volumes, contributing to sustainability and waste reduction.</p>

- Q: This question asks for a method to determine the quantity of aluminum extrusions required for a particular project.

- <p>To calculate the amount of aluminum extrusions needed for a specific project, follow these steps: 1. Determine the dimensions and design of the project to understand where and how aluminum extrusions will be used. 2. Calculate the length of each extrusion piece required based on the project's structure. 3. Multiply the number of pieces by the length of each piece to get the total length of aluminum needed. 4. Consider any additional factors such as waste, tolerances, and potential design changes. 5. Consult with an aluminum supplier or use specialized software for more precise calculations, especially for complex projects. Always account for a margin of error and additional material for contingencies.</p>

- Q: What are the different packaging options for aluminum profiles?

- There are several packaging options available for aluminum profiles, depending on the specific requirements and preferences of the customers. Some of the common packaging options include: 1. Bundles: Aluminum profiles can be packed in bundles, where several profiles of the same length and shape are bundled together using straps or bands. This packaging option is ideal for smaller profiles and offers easy handling and transportation. 2. Wooden crates: For larger or more fragile aluminum profiles, wooden crates are often used. The profiles are securely placed inside the crate and then nailed or screwed shut. Wooden crates provide excellent protection during shipping and can be customized to fit the specific dimensions of the profiles. 3. Cardboard tubes: Thin and lightweight aluminum profiles, such as those used in the packaging industry, can be packaged in cardboard tubes. These tubes provide a cost-effective and lightweight solution for transportation and storage, while still offering adequate protection. 4. Pallets: When dealing with a large volume of aluminum profiles, pallets are often used for packaging. Profiles are stacked and secured on a pallet using strapping or shrink wrap. This packaging option allows for efficient handling, as pallets can be easily loaded and unloaded using forklifts or pallet jacks. 5. Custom packaging: Customers may have unique packaging requirements based on their specific needs. In such cases, custom packaging options can be developed, such as foam inserts, plastic wraps, or specific labeling. Custom packaging ensures that the profiles are adequately protected and that any specific handling instructions are followed. In summary, the packaging options for aluminum profiles can vary depending on factors like profile size, fragility, and volume. Whether it's bundling, wooden crates, cardboard tubes, pallets, or custom packaging, each option offers its own benefits in terms of protection, handling, and ease of transportation.

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Can aluminum profiles be used for stage and event structures?

- Stage and event structures can indeed make use of aluminum profiles. Aluminum, being both lightweight and durable, is a widely utilized material in the construction industry for a range of purposes, including stage and event structures. Aluminum profiles possess versatility, allowing for easy shaping, cutting, and joining to create customized structures. With an excellent strength-to-weight ratio, they are well-suited for supporting heavy equipment and ensuring the safety of performers and audience members. Moreover, aluminum profiles can be powder-coated or anodized, providing both a decorative finish and protection against corrosion. This enhances the visual appeal and longevity of the structures. In conclusion, aluminum profiles are a popular option for stage and event structures due to their versatility, strength, and aesthetic qualities.

- Q: This question asks about the various types of aluminum profiles that are specifically used for the purpose of insulating exterior walls.

- <p>Aluminum profiles for exterior wall insulation are crucial for thermal efficiency and structural integrity. Common types include: 1. <strong>Aluminum Cladding Profiles</strong>: These cover the insulation and provide a weather-resistant barrier. 2. <strong>Aluminum Insulation Fin Profiles</strong>: Used to create a gap for insulation material between the wall and the cladding. 3. <strong>Aluminum Casing Profiles</strong>: These encase the insulation, providing a finished look and additional protection. 4. <strong>Aluminum Angle Profiles</strong>: Used for corners and edges to maintain structural integrity. 5. <strong>Aluminum Trim Profiles</strong>: For finishing touches and to cover gaps or seams. Each type serves a specific function in the insulation system, ensuring energy efficiency and a durable exterior wall construction.</p>

Send your message to us

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords