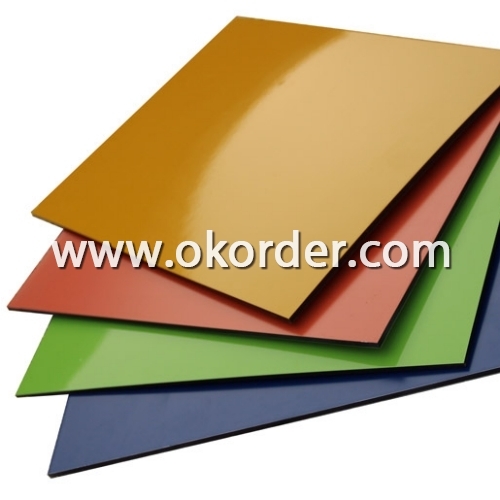

Aluminum Composite Panel 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Aluminium Composite Panel 1060

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel 1060:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: Is it possible to recycle aluminum cans and turn them into new cans?

- <p>Yes, aluminum cans can be recycled into new ones. The recycling process involves melting the used cans, which is much less energy-intensive than extracting and refining new aluminum from bauxite ore. Once melted, the aluminum can be reshaped into new cans or other products. This process is not only environmentally friendly but also economically efficient, as it saves energy and reduces waste.</p>

- Q: Is it possible to utilize recycled aluminum in the manufacturing of solar panels or wind turbines?

- <p>Yes, recycled aluminum can be used in the production of solar panels and wind turbines. Recycled aluminum is often used in the manufacturing process due to its properties such as low density, high strength, and excellent corrosion resistance. In solar panels, it can be used for the frame and mounting structures, while in wind turbines, it is commonly used for the construction of the turbine blades and other components. The use of recycled aluminum not only reduces the environmental impact of mining new aluminum but also contributes to the sustainability of renewable energy technologies.</p>

- Q: Describe the environmental impact of discarded aluminum.

- <p>Discarded aluminum can have significant environmental impacts. It contributes to land and water pollution, as it does not biodegrade and can leach harmful substances into the soil and water. Additionally, aluminum can disrupt the food chain when ingested by wildlife, potentially leading to health issues. The production of aluminum is energy-intensive, so recycling it reduces the demand for raw materials and decreases greenhouse gas emissions. However, improper disposal can lead to the release of toxic substances during the recycling process, further harming the environment.</p>

- Q: This question asks about the methods to determine the safety of a specific brand's aluminum products.

- <p>To determine if a particular brand of aluminum products is safe to use, one should look for certifications and standards compliance. Check if the brand has certifications such as ISO 9001 for quality management systems or specific safety certifications relevant to aluminum products. Look for compliance with safety standards like ANSI, ASTM, or EN standards. Additionally, research customer reviews and testimonials, and consider third-party lab testing results. It's also important to inquire about the manufacturing process to ensure it adheres to environmental and health safety regulations. Lastly, consult with industry experts or regulatory bodies for their assessment of the brand's safety practices.</p>

- Q: Explain how the inclusion of copper in aluminum alloys influences their strength and ductility.

- <p>Adding copper to aluminum alloys significantly increases their strength, particularly in the form of tensile and yield strength. Copper acts as a hardening agent, creating a more rigid structure within the alloy. However, this increase in strength often comes at the expense of ductility. As copper content rises, the ductility of the aluminum alloy decreases because copper reduces the alloy's ability to deform under stress without fracturing. The balance between strength and ductility is crucial in alloy design, as higher strength alloys may be less suitable for applications requiring formability and flexibility.</p>

- Q: This question asks for common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. Some applications include: 1) Food and beverage cans for preserving food and drinks. 2) Aluminum foil used for cooking and food storage. 3) Construction materials, such as window frames and roofing. 4) In transportation, like car parts and airplane components to reduce weight. 5) Electrical wiring due to its high conductivity. 6) Household items like pots and pans, and furniture. 7) Packaging materials for various products. 8) In sports equipment like bicycle frames and tennis rackets. These applications highlight aluminum's versatility and importance in everyday life.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum as a material in construction projects.

- <p>Aluminum in construction offers several advantages, including its lightweight nature, which reduces structural load and facilitates easier transportation and installation. It is also highly resistant to corrosion, making it ideal for outdoor applications and in areas with harsh weather conditions. Aluminum's recyclability contributes to sustainability, and it has a high strength-to-weight ratio, enhancing structural integrity. However, it has some disadvantages, such as being a poor conductor of heat, which may require additional insulation. It can also be more expensive than traditional materials like steel or concrete, and it dents easily, necessitating careful handling and maintenance.</p>

- Q: This question asks for recent applications of aluminum in contemporary society.

- <p>Aluminum has found new uses in modern society across various sectors. In the automotive industry, it is used to manufacture lightweight vehicles for fuel efficiency and reduced emissions. In construction, aluminum is utilized for building facades, window frames, and roofing due to its durability and low maintenance. The aerospace industry also relies on aluminum for aircraft construction because of its strength-to-weight ratio. Additionally, aluminum is used in electronics for heat sinks and casings, and in the packaging industry for food and beverage cans. It's also gaining traction in the energy sector, particularly in battery technology for electric vehicles and renewable energy storage solutions.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords