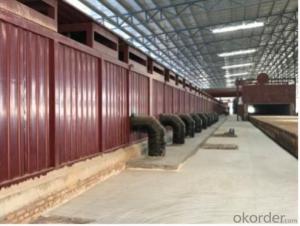

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

tube dryer specifications:

reasonable structure

high efficiency

low energy consumption

convenient transportation

Tube Dryer is formed by rotary body, lifting blade, driving device, supporting device and sealing ring. It can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used. The Rotary Dryer is used for drying materials with humidity or granularityin the industries of mineral dressing, building material, metallurgy and chemical.

Dryer main application:

The indirect heat transfer dryer made by our company can be used in building materials, metallurgy, chemical industry, cement plant for drying of limestone slag, coal powder, slag, clay stone.

Dryer usage:

This series drier is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical. Rotating dryer can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used.

Dryer features:

Widely used in drying different materials!

reasonable structure,high efficiency

low energy consumption

Specifications of Drier

Specifications (m) | Diameter of rotary body | Length of rotary body | Angle of slope | Weight | Inlet temperature () | Capacity |

GZφ600×6000 | φ600 | 6 | 3 | 2.9 | ≤700 | 0.5-1.5 |

GZφ800×8000 | φ800 | 8 | 5 | 3.5 | ≤700 | 0.8-2.0 |

GZφ1000×9000 | φ1000 | 9 | 5 | 5.2 | ≤700 | 0.8-2.5 |

GZφ1000×10000 | φ1100 | 10 | 5-3 | 5.6 | ≤700 | 1.0-3.5 |

GZφ1200×10000 | φ1200 | 10 | 3-5 | 14.04 | ≤700 | 1.8-5 |

GZφ1200×12000 | φ1200 | 12 | 3-5 | 14.8 | ≤700 | 2-6 |

GZφ1500×12000 | φ1500 | 12 | 3-5 | 17.76 | ≤800 | 3.3-7.5 |

GZφ1800×14000 | φ1800 | 14 | 3-5 | 29 | ≤800 | 5-9 |

GZφ2200×12000 | φ2200 | 12 | 3-5 | 33 | ≤700 | 6-12 |

GZφ2200×18000 | φ2200 | 18 | 3-5 | 53.3 | ≤800 | 10-15 |

GZφ2200×20000 | φ2200 | 20 | 3-5 | 56 | ≤800 | 15-25 |

GZφ3000×20000 | Φ3000 | 20 | 3-5 | 78 | ≤800 | 25 |

GZφ3000×25000 | Φ3000 | 25 | 3-5 | 104.9 | ≤800 | 32-36 |

- Q: What is the best drying equipment?

- Through the filter to make hot air purification, and then by the left shunt plate to the layers, so that the average hot air through each layer of dry material.

- Q: What are the basic types of common drying equipment?

- (2) Belt Dryer Belt Dryer consists of several independent unit segments. Each unit section includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. On the drying medium quantity, temperature, humidity and exhaust gas circulation operating parameters, can be independently controlled, so as to ensure the reliability of working with dry and operating conditions optimization.

- Q: What are the common types of dryers?

- The belt dryer consists of a number of individual unit segments, each of which includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. The amount of drying medium, temperature, humidity and exhaust cycle

- Q: What are the common drying methods?

- Is the use of moisture to remove gas, liquid, solid material in a small amount of water, due to moisture dehumidifier dehumidification capacity is limited, only used to remove trace moisture in the material, so the production of very little.

- Q: How to solve the dryer a series of failures

- The moisture absorption capacity of the dryer is limited, so the moisture it adsorbs must be removed by regeneration. The process is: when the ambient air is inhaled, through a filter into the blower, and then be sent to a group of heaters. The heated air passes through the machine. When the temperature of the dryer rises, the adsorbed moisture is released. When the hot air to absorb water vapor to saturation, it was discharged into the atmosphere. The high temperature regenerative dryer must be cooled before returning to the dry loop to restore the moisture absorption function of the dryer.

- Q: How to choose the right drying equipment and drying technology

- For non-hygroscopic materials, the moisture present in any environment remains on the surface and becomes "surface moisture" and is easily removed.

- Q: What are the types of drying equipment?

- According to the heating method, the dryer is divided into convection, conduction, radiation, dielectric and other types. Convection dryer, also known as direct dryer, is the use of hot dry media and wet material in direct contact with convection way to transfer heat, and the generated steam away; Conductive dryer also known as indirect dryer, which uses conduction The heat is transferred from the heat source through the metal wall to the wet material, and the resulting wet steam can be removed by means of reduced pressure suction, passing a small amount of purge gas or condensing it on a separately provided low

- Q: Frozen sublimation drying equipment which consists of several systems

- the control system: the control system consists of a variety of monitoring the original, an umbrella device, instrumentation and other components, a higher degree of automation control system can be set by the freeze-drying process automatically operate, while the vacuum, heating plate temperature and cooling System monitoring and alarm, record all kinds of data.

- Q: What are the characteristics of the drum dryer?

- The current resistance is small, you can use it to dry the granular material.Currently the development of domestic drum dryer has been in the world advanced level, from the practical sense, the drying device in addition to improving the shape of the internal device design, gas transport regulation and other details Factors, in other areas no longer have the technical leap and innovation, the current technology has been able to meet the general needs.

- Q: What is a combination of drying equipment?

- Combination drying equipment is a combination of two or more dry forms, the main material, mainly in series, that is, when the material has been through the drying equipment, two or more drying equipment, combined dry mainly to meet a The need for a drying process.

Send your message to us

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords