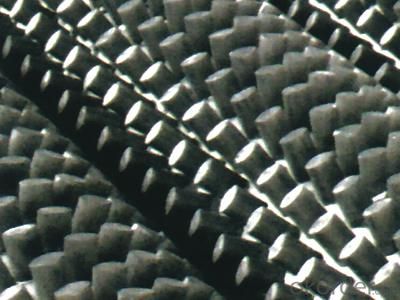

Studded Tube / Finned Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GROUP mainly produces the following products:

l Refinery/chemical furnaces, incinerators, coal (liquid) chemical reformers

l Waste heat boilers, thermal medium boilers

l Class A1 /A2 pressure vessels

l Reactors, Heat Exchangers & Towers

l Oil tanks/accessories/mixers, alloy steel precision castings

l Four classes of piping supports and hangers used in fired-electric/thermo-electric/nuclear electric power industries and dampers

l Flue gas/air/coal powder duct and its attachments

l Boiler ancillaries, water treatment devices and so on

GROUP obtains the following certificates:

l Class A Certificate of Engineering Design

l Design License of Pressure Vessel (Class A3)

l Manufacture License of Pressure Vessel (Class A3)

l Design & Manufacture License of Pressure Piping (Class A)

l Manufacture License of Waste heat boilers (Class A), thermal medium boilers

l ISO 9001:2000 Quality Management System

l ASME U and ASME S

l Enterprise Credit: AAA

As the Leading Enterprise of Fired Heaters, Corporation can design and fabricate common Fired Heaters as well as uncommon ones independently such as Reactor Charge Heater for Straight-run Gasoline Hydrogenation Unit (7*104 t/a), 6t/d Testing Unit for Direct Liquefaction, Coal Liquefaction Reactor Heater for Stable Unit of Coal Liquefaction and Hydrogenation, Two-stage Fired Heater for Pyrolysis Gasoline hydrogenation Unit of Ethylene Technical Reform (7.2*105 t/a), Reboiler for Depentanizer of Aromatic Hydrocarbon Unit (2.5*105 t/a), Reboiler for Reboiling Deheptane Tower, Four-in-one Reforming Heater for Reforming Project (2*105 t, 6*105 t, 8*105 t), Acetylene Cracking Heater for PTMEG Unit, etc.

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: What are the advantages of a vacuum furnace?

- Energy consumption is lower than salt bath furnace. Modern advanced vacuum industrial furnace heating chamber is made of high quality heat insulation material and wall, which can concentrate electric heating energy into heating chamber with remarkable energy saving effect.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Furnace industry is not generally Mason walls, needs to have a professional operation and rich construction experience, high level of industrial furnace is difficult to get.

- Q: Brief introduction to repair of industrial furnace

- The industrial furnace is the main production equipment in the machinery industry. The repair of industrial furnace directly affects the quality, high yield, long life, low consumption and safe production of the furnace.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

Studded Tube / Finned Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords