ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZrO2 14.5% AR glass fiber roving

AR glassfiber spray roving is used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Specification of 14.5% Zro2 AR Glassfiber roving:

1.ZrO2 14.5% & 16.5%

2.2400Tex

3.Filament dia 15um

4.Moisture Content 0.09%

5.Breaking Strength 0.28N/tex

Technical Data of 14.5% Zro2 AR Glassfiber roving:

ZrO2 Content | % | JC935-2004 | 14.5±0.8 | 14.8 |

TiO2&ZrO2 Content | % | ≥19.2 | 19.3 | |

Filament dia | um | GB/T7690.5-2001 | 15±2 | 15 |

Strand tex | tex | GB/T7690.1-2001 | 2400±240 | 2460 |

Breaking Strength | N/tex | GB/T7690.3-2001 | ≥0.25 | 0.28 |

Moisture Content | % | GB/T9914.1-2001 | ≤0.2 | 0.09 |

Combustible Content | % | GB/T9914.2-2001 | 0.8-2.0 | 1.35 |

Stiffness | mm | GB/T7690.4-2001 | ≥120 | 150 |

Specific gravity | g/m3 | / | / | 2.7 |

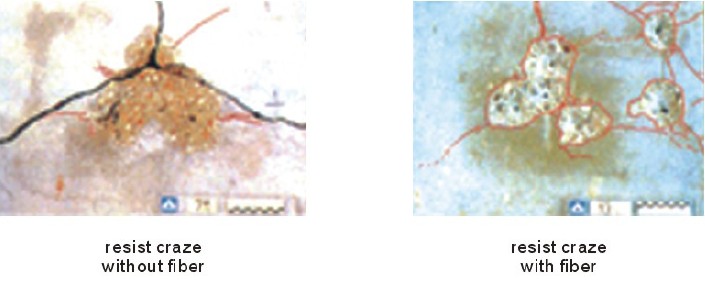

Crack Test on 14.5% Zro2 AR Glassfiber roving:

Pallet Packing of 14.5% Zro2 AR Glassfiber roving:

1. Each pallet has 3 or 4 levels ,16rolls /level. 860-1150kg/pallet.

2. 20pallets/1x20”GP 17-20MT/1x20’GP

- Q: I have called to 100s cement companies in US, nobody knows about that type of cement even though I know such cement exists. Please help!

- Price!!! Im building a house in Mexico. Its the first house I have ever built so im learning a lot. But let me tell you from my experience. Building out of brick and cement is a lot more expensive and difficult than wood. If built right, a brick house can last for centuries. A brick house can have all the look of a wood house too. Which is what most american like and are used to. The cost though, is greater for the bricks. Brick houses are still build in the US, but not too often.

- Q: hey im zack and im reseachin portland cement u think u guys help me i want to find out what is it and how its used? THANKS 4 UR HELP AND TIME

- Steel and Portland cement are what the whole world is made out of ! It is one of the two most important substances known to man. It is very strong in compression (squeezing) but very weak in tension (pulling) so you put steel rebar rods in the concrete. Then you have to best of everything. Portland cement can be mixed to have low or high strength

- Q: How do you make cement?

- Please be clear. Do you mean how do you make concrete? or how do you make cement? If you mean how do you make concrete, get 1 part cement, 2 parts sand and 4 parts gravel, mix with water until it's a stiff workable consistancy. Wait 24 hours for concrete to become reasonably cured to continue construction.

- Q: I need a list of cement, concrete and aggregates Public companies the most important ones or largest Co.!

- here are some of the largest: cemex holcim ltd lararge florida rock there are many others, go to yahoo finance, they will list may others. Hope this helps.

- Q: how many bags of portland cement do I need to build a slap of 40m by 30 m by 10cm?

- Contact Portland Cement, their reps will be able do the calculations for you. They will need to know which Portland cement product you are using.

- Q: cement industries

- Although I am not first hand in the cement/concrete industry, water extends the tooling's life and most important, it keeps the dust down so you have a lesser chance of getting lung disease from the dust. I forget what it's called right now. We do a lot of core drilling in our line of work those are the reasons for the water.

- Q: i need to paint cement. either in the process of doing the cement or after when its dry? which way is the best? it has to be really durable, waterproof.

- Is this near/around a pool or water source? Cement must be sealed, then painted. Go to B. Moore paints or Bear paints. Lowes Home center carries both I think. The paint for cement is a special blend that must be used. Can use paint sprayer.

- Q: how to get rubber cement of the front of a picture?

- Rubber cement eraser. Its useful for just such an occasion. It looks a bit like French Toast.

- Q: Is the cement industry in the stock a separate plate? Or part of the other plate?

- Now can be considered a sub-section, there are several leading enterprises

- Q: The different meaning of Cement Clinker and Clinker?

- Clinker is ground (usually with the addition of a little calcium sulfate) to become Portland cement. It may also to be interground with other active ingredients to produce: blastfurnace slag cement pozzolanic cement silica fume cement Clinker, if stored in dry conditions, can be kept for several months without appreciable loss of quality. Because of this, and because it can easily be handled by ordinary mineral handling equipment, clinker is traded internationally in large quantities. The freight cost is much lower than that for the equivalent amount of finished cement. Cement manufacturers purchasing clinker grind it as an addition to their own clinker at their cement plants. Manufacturers also ship clinker to grinding plants in areas where cement-making raw materials are not available. Happy Holidays !

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords