Woven Roving Fiberglass Canoe - AR Spray Up Roving ZRO2 14.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

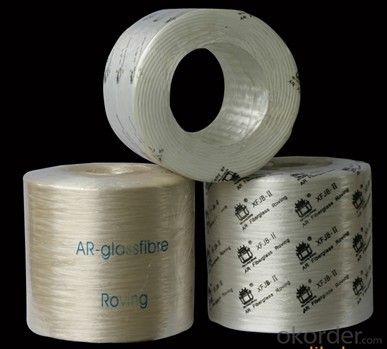

AR glass chopping roving mainly designed for use in the manufacture of GRC composites by the manual spray method. Our Roving is designed for optimum processability. It is used in the manufacture of GRC architectural panels and other building elements, civil engineering and infrastructure components.

Properties

Easy chopped

Good integrity

Excellent dispersibility and alkali resistant;

been approved by Sheffied University,UK.

Technical specifications:

linear weight of roving(tex) | Sizing content(%) | Moisture(%) | Stifness(mm) | Breaking strength(N/tex) |

JC/T572-2002 | JC/T572-2002 | JC/T572-2002 | JC/T572-2002 | JC/T572-2002 |

2400±240 | 1.3±0.2 | ≤0.2 | ≥120 | ≥0.25 |

Pallet Packaging

Each pallet has 3 or 4 levels ,16rolls /level.

The complete pallet is enclosed in polythene and identified with two labels.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What is the function of adding fiber material to concrete ?

- In projects, some fiber materials such as paper, hemp fiber and straw are added to concrete. If plastering mortar is added into mixer, it can play the role of skeleton, improve the crack resistance and tensile strength of the plaster layer and enhance the flexibility of floated coat and durability in order to reduce floated coat contraction and make it not easy to fall. The characteristics of the fiber material will be introduced as follows: firstly, paper reinforcement includes dry and wet paper. Dry paper is use at the time of adding quick lime, It was tore up, was removed dust and soaked with water, and then 100 kg lime and 2.75 kg paper are mixed. When using, it should be made into powder by a small steel mill and 3 mm aperture sieve filter. When wet paper reinforcement (commonly known as pulp) was used, each 100 kg lime should be added into 2.9 kg wet paper reinforcement. Specific operation method is the same as that of dry paper. Secondly, the use of hemp fiber requires tenacity and purities. To make is loose, it need to be dried, linen and then it is cut into 20 mm to 30 mm. Each 100kg lime adds 1kg loose hemp which is hemp fiber grey. Thirdly, grass stalks are usually cut into rice straw or wheat straw which is no more than 30 mm long. It could be used after half a month after soaked in lime water. It also can be used as paper after soaked in lime or caustic soda. Fourthly, synthetic fiber mainly includes polypropylene fiber and nylon fiber used for mortar. When using, you should pay attention to its disparity and alkali resistance. These are the all material fiber used in concrete. You should be familiar with the characteristics of the material in order to make better use of it.

- Q: How to make a glass fiber reinforced plastic?

- The answer is no. The glass fiber reinforced plastic grille can be made with a mold, so it would be very easy to do it, while by manual, it would be troublesome, and do not have compressive property.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: HS code for alkali-free glass fiber yarn

- The HS encoding the alkali-free glass fiber roving yarn is 70191200 and chopped yarn, spinning and Chinese HS EU tariff as follows, S and Z. Spun yarn is a spinning twist E-glass fiber. My question is whether it is yarn or spun yarn. If it is yarn, it would be twistless.

- Q: The use of glass fiber cloth

- Reinforced material:

- Q: What can glass fiber do?

- Building for external wall insulation layer, glass fiber clothes are used in the glass fiber industry. The main effect is to increase the strength.

- Q: Epoxy resin mortar mix ratio

- 200 to 300 of mortar and 100 of epoxy resin will be fine. It should be added according to concentration. Construction convenient and high quality can be reported as the premise.

- Q: Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

Send your message to us

Woven Roving Fiberglass Canoe - AR Spray Up Roving ZRO2 14.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords