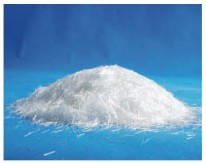

Water Dispersed Strand-Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Kgs kg

- Supply Capability:

- 80000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introdution of Water Dispersed Strand-Zirconia 16.5%:

Water dispersed chopped strand is mainly used in the reinforcement of gelled material such as cement, gypsum. The fibers disperse best when the viscosity of mortar at 4-20%; It improves homogeneousness and bearing capacity of panels and prevent cracks, when dosage reaches more than 1%. They incorporate easily into mixes giving a very large number of distributed reinforcing fibers from a small weight of product.

Usage of Water Dispersed Strand-Zirconia 16.5%:

Water dispersed chopped strand is typically used at a low level of addition to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.

Technical Data of Water Dispersed Strand-Zirconia 16.5%:

Zirconia Content(%)≥ 16.5%

Strand length: 4mm-36mm

Strand tex: 76tex

Filament da: 13μm

Moistrue content(%):>0.1

Size content(%)≥ 1.6

Breaking Strength(N/tex)≥ 0.23

Package of Water Dispersed Strand-Zirconia 16.5%:

Pallet package and carton package for choice, and also special package is also available.

- Q: it can't be reused because of the heat exposureor also a building that has been torn down

- The concrete can be used for fill to raise the level of the ground at the edge of a slope to provide more level ground.

- Q: does anyone have any experience in that? does it reduce the noise a lot or just a bit? and about the ceiling... my neighbors throw and drag things on the floor (they're mental cases, fruitcakes). i can't afford to move right now because the house is bought so i'd have to sell and buy another house. can't do that right now. and it always costs money.to what extent will the cement on the ceiling reduce the noise?what kind of windows are the best?thank you all...

- Double-paned windows will buffer exterior noise considerably (and maintain your energy costs, too) but cement on the ceiling? Nope. All sound in your space will be magnified

- Q: It's gray and turns all hard, where do they get the ingredients and how come there never seems to be a short supply of it?

- Cement is made by baking/firing gypsum rock to drive off the chemically bound water. I live in Dallas and we have millions of tonnes of it just below the topsoil which can be seen in road cuts and in names like White Rock Lake.

- Q: ok im thinking of remodeling and there is a hideous cement floor, i want a carpet...How do i do it? thank you

- install tack strip, lay padding, install carpet. They make tack strip with concrete nails(hardened nails to drive into concrete)

- Q: What kind of cement (and where can I get it $$$$) can I use to replace it without going back to the dentist?

- You definantly need to go back to the dentist... there is no way around that one!?!?

- Q: the house is from 1959. Before I bought it the owners re-landscaped without any consideration for water flow thus causing the basement to have seepage through the walls. I fixed the water flow issue (1.5 years dry) but now I have painted cement walls that have paint pushed out/peeling with a few visible cracks and wonderful mineral deposition. I really don't want to spend the time with the metal wire brush to strip the paint off so I would like to just use hydraulic cement over the whole wall and then use a water sealing paint over the top. Is this a good idea? other suggestions?

- That sounds more time consuming than just scraping off the peeling paint..... Here's 1 problem w/your approach, latex paint dries so fast that it actually creates a vacuum effect in doing so, which means that as it dries it'll pull off the surface anything that's not firmly attached, which is why prep work's so important to longevity. You won't immediately notice this happening, but w/the passage of time you'll be back to the peeling wall in spades. I've never heard of skim-coating w/hydraulic cement, but I've done plenty of patching plaster walls w/plaster of paris, what immediately comes to mind are the inherent problems w/working in a medium that sets up so quickly, I can't imagine how you'd get a whole wall covered looking even satisfactory (but I'm pretty picky, I figure when people are paying me I'm obliged to do a better job than they could've) w/out going insane in the process. I learned the trick to plaster, but I don't know the chemistry of hydraulic cement well enough to find a retardant for it. Anyways, I know prep-work sucks, but often it's just easiest to do it get it over with (start w/a stiff putty knife, by the way) rather than inventing a new process having to deal w/a long string of learning curves as you go. The first question that came to mind w/your question is have you ever skim-coated anything before so that you'd have even a vague idea of what you're getting yourself into potentially, but if you must create, than by all means go forth!

- Q: how many bags of cement will i need for a12x12 patio?

- For best installment, 12x12x4 inch. is 1.78 yards You'll need 81-80lb bags

- Q: I know the cement board is supposed to be cut 1/4 inch above the rub flange, but what if you install the cement board and there is a big enough gap between the tub and the wall that when installing tile, the tile still would not be even with the tub flange let alone go over the flange? After installing the cement board, there is still about a .5 inch gap from the wall to the tub. I assume you can install tile and then caulk along the small gap from the tub flange to the tile. But let me know your thoughts.

- Sounds like you should have furred out you framing before installing the cement board. Short of removing the cement board you could add another layer.

- Q: i need to paint cement statues What do i paint them with. how do i paint them and where do i buy this paint? thanks:)

- you okorder also check out a large art supply company such as Dick Blick

- Q: if i filled a balloon with air, covered it with cement, waited a few hours, deflated the balloon, pulled the balloon out, could i create a hollow cement sphere?????

- Yes, in fact it has been done, though it's a little more complicated than you describe. The problem is that wet cement is pretty soupy, and it's hard to get it to form a layer around the baloon. So you also need an outer form around the layer of cement. That could be made of cardboard and duct tape on a small scale, and cut away after the cement has hardened. You can pop the balloon and slip it out through the hole. The interior void will not be exactly spherical, of course.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1991 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Water Dispersed Strand-Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Kgs kg

- Supply Capability:

- 80000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords