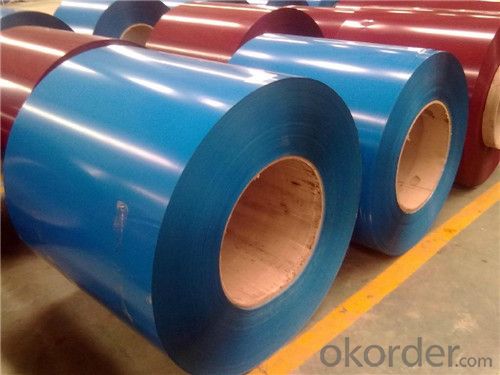

Z42 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z42 BMP Prepainted Rolled Steel Coil for Construction

Description of Z42 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z42 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z42 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z42 BMP Prepainted Rolled Steel Coil for Construction

Product | Z42 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z42 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being cut and shaped into the desired size and design. The coils are typically processed through a roll forming machine which bends and molds the steel into the required shape for the shelves. This process allows for high efficiency and precision in creating uniform and durable storage shelves.

- Q: What are the different coil coating options available for steel coils?

- There are several different coil coating options available for steel coils, each offering unique benefits and applications. 1. Polyester Coil Coating: Polyester coil coatings are the most commonly used option due to their affordability and versatility. These coatings provide good durability, weather resistance, and color retention, making them suitable for a wide range of indoor and outdoor applications. 2. Polyvinylidene Fluoride (PVDF) Coil Coating: PVDF coil coatings offer excellent resistance to fading, chalking, and chemical exposure. They are highly durable, making them ideal for exterior applications where long-term performance is required. PVDF coatings also have good dirt and stain resistance. 3. Polyurethane Coil Coating: Polyurethane coil coatings provide exceptional adhesion and flexibility. They are often used in applications where the steel coils require excellent resistance to abrasion, impact, and corrosion. Polyurethane coatings also offer good color retention and weather resistance. 4. Silicone Modified Polyester (SMP) Coil Coating: SMP coatings combine the benefits of polyester and silicone coatings. They offer enhanced resistance to chalking, fading, and industrial pollutants. SMP coatings are commonly used in agricultural, industrial, and architectural applications. 5. Polyvinyl Chloride (PVC) Coil Coating: PVC coil coatings provide excellent chemical resistance and are frequently used in applications where resistance to acids, alkalis, and solvents is critical. These coatings also offer good color retention and have a low environmental impact. 6. Epoxy Coil Coating: Epoxy coatings provide exceptional adhesion and corrosion resistance. They are often used in demanding environments such as marine or chemical processing industries. Epoxy coatings can be formulated to meet specific performance requirements, making them highly customizable. 7. Acrylic Coil Coating: Acrylic coatings offer excellent color retention, UV resistance, and gloss retention. They are commonly used in architectural applications where aesthetics are important. Acrylic coatings also provide good resistance to weathering and chemicals. It is important to consider the specific requirements of the application when choosing a coil coating option. Factors such as durability, weather resistance, chemical resistance, adhesion, and color retention should be taken into account to ensure the best performance and longevity of the steel coils.

- Q: What are the common applications of cold-rolled steel coils?

- Due to its exceptional qualities, cold-rolled steel coils find a wide range of common applications across various industries. The automotive industry extensively uses these coils to manufacture car parts like body panels, chassis components, and structural reinforcements, benefiting from the high strength and excellent formability of cold-rolled steel. Similarly, the construction industry relies on cold-rolled steel coils to fabricate structural elements for buildings and infrastructure. Beams, columns, and other load-bearing components are commonly made from cold-rolled steel due to its superior strength and durability. Appliances and consumer goods manufacturing also make use of cold-rolled steel coils. They are frequently employed to create the outer shells of refrigerators, washing machines, and ovens, thanks to the smooth and consistent surface finish that provides an aesthetically pleasing appearance. Furthermore, the electrical industry utilizes cold-rolled steel coils in the production of electrical enclosures, transformers, and various other components. The excellent electrical conductivity and magnetic properties of cold-rolled steel make it a preferred choice for such applications. In summary, cold-rolled steel coils have diverse applications in industries including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it the favored choice for manufacturers across various sectors.

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil vary based on its intended use and manufacturer. However, a common range for the inner diameter is between 508 to 610 millimeters (20 to 24 inches), while the outer diameter can range from 1,200 to 2,000 millimeters (47 to 79 inches). The width of a steel coil can range from around 600 to 2,000 millimeters (24 to 79 inches), and the weight can vary from a few hundred kilograms to several metric tons.

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a common method used to join steel coils together, whether for manufacturing purposes or repair work.

- Q: What are the different methods of corrosion protection for steel coils?

- There are several methods of corrosion protection for steel coils, including but not limited to: 1. Coating: Applying a protective layer such as paint, polymer, or zinc coating on the surface of the steel coil to prevent direct contact with corrosive agents. 2. Galvanizing: Immersing the steel coil in a bath of molten zinc, creating a protective coating that prevents corrosion. 3. VCI (Vapor Corrosion Inhibitor): Using volatile corrosion inhibitors that release molecules to form a protective layer on the steel coil, preventing corrosion. 4. Oil or Wax Coating: Applying a layer of oil or wax on the surface of the steel coil to act as a barrier against moisture and corrosive elements. 5. Cathodic Protection: Using sacrificial anodes or impressed current to protect the steel coil by providing a more easily corroded metal that attracts corrosion instead. 6. Desiccants: Placing desiccant materials such as silica gel or molecular sieves inside the packaging to absorb moisture and prevent corrosion. 7. Environmental Control: Maintaining controlled humidity levels, temperature, and proper ventilation in storage areas to minimize the risk of corrosion. 8. Proper Handling and Storage: Implementing safe handling practices during transportation and storing steel coils in dry, covered areas away from corrosive substances. It is important to select the appropriate method based on the specific application, environment, and desired level of protection for the steel coils.

- Q: how much pressure can steel withstand? and how much pressure can concrete withstand? per m3 or cm3? thanks

- A common allowable stress for steel is 24,000 psi for A36 steel. Note that allowable stress is a working stress that is less than ultimate stress the stress at which the material will rupture. This allowable stress keeps the steel within the elastic range. Concrete allowable stress is typically around 3000 psi. Concrete, though, being a mixed material has variable values for allowable stress. Reinforced concrete design theory suggests that concrete should not be considered to be able to carry much, if any, tensile force. This explains why you will see steel rebar or reinforcing bars cast in to the concrete. The steel is there to carry any tensile forces, while the concrete is there to carry compression forces. This is a VERY basic explanation. There are entire books on both of these subjects...

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel coils have a longer lifespan and require fewer repairs and replacements. This reduces the overall environmental impact associated with construction activities. Additionally, steel is a highly recyclable material, with most steel coils containing a significant amount of recycled content. This promotes a circular economy and reduces the demand for new raw materials. Moreover, steel coils are lightweight and versatile, allowing for more efficient transportation and installation, thereby reducing energy consumption and emissions during construction. Overall, the use of steel coils in construction promotes sustainability by offering durability, recyclability, and energy efficiency.

- Q: What are the common problems faced during steel coil production?

- Some common problems faced during steel coil production include surface defects such as scratches or dents, dimensional inconsistencies, coil breakage, edge wave formation, and coil slitting issues. Other challenges may include coil corrosion, improper coil cooling, and quality control issues.

- Q: Are steel coils used in automotive manufacturing?

- Yes, steel coils are commonly used in automotive manufacturing. They are used to produce various components such as body panels, chassis parts, and suspension components. The high tensile strength and durability of steel make it an ideal material for creating safe and robust automobiles.

Send your message to us

Z42 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords