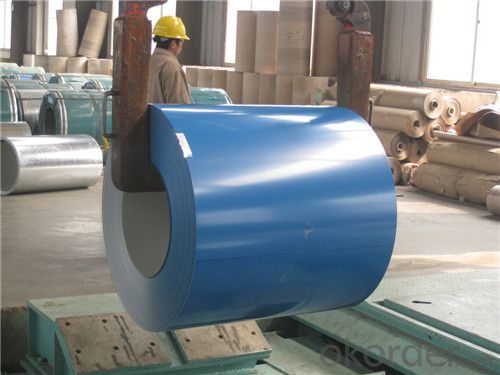

Z17 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 98 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z17 BMP Prepainted Rolled Steel Coil for Construction

Description of Z17 BMP Prepainted Rolled Steel Coil for Construction

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z17 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

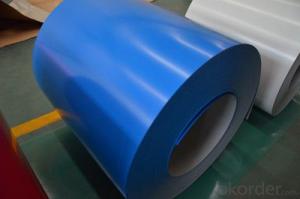

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z17 BMP PPGI Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z17 BMP Prepainted Rolled Steel Coil for Construction

Product | Z17 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z17 BMP Prepainted Rolled Steel Coil for Construction

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications including manufacturing aircraft components, structural supports, and engine parts. The coils are typically processed and shaped into specific forms such as sheets or plates, which are then used to construct critical components of aircrafts, ensuring strength, durability, and performance.

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a common method used to join steel coils together, whether for manufacturing purposes or repair work.

- Q: What are the pros and cons to selecting a graphite shaft sand wedge over steel shaft?

- Graphite Shaft Wedges

- Q: Can steel coils be coated with copper?

- Yes, steel coils can be coated with copper. This process, known as copper coating or copper plating, involves applying a thin layer of copper onto the surface of the steel coils to enhance their corrosion resistance, conductivity, and aesthetics.

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- It's okorder / Stainless steel Grades [list is not exhaustive] 200 Series—austenitic chromium-nickel-manganese alloys 300 Series—austenitic chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Good weldability. Better wear resistance and fatigue strength than 304. Type 302—same corrosion resistance as 304, with slightly higher strength due to additional carbon.

- Q: hey therejust wondering about changing nylon strings to steel strings...i have an acoustic guitar and it has nylon strings, but i was thinking about switching to steel strings, as i think it sounds better.this might sound really stupid... but is that possible? i mean they call it a steel stringed GUITAR and nylon stringed GUITAR, so if i wanted to switch would i have to get a whole new guitar? please help, im reaaally confused!thanks

- I asked my guitar teach this and the thing with changing from nylon strings to steel strings is that the nylon tuning forks are accustomed to nylon and tend to slip. But, in say that you can do it, but, you would have to wait awhile for them to start sticking. If i have helped the Your welcome and Thanks! =]

- Q: ex: boat hull made out of steel

- egg yolk. it really works. i know this because i built a surfing bicycle (yeah) that had steel on it.just let the steel soak in the yolk for about 3-4 hours and let it dry in a dark area. this will work.

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Steel coils are used in the manufacturing of automotive accessories as they are processed and shaped into various components such as brackets, frames, and supports. These coils are typically cut, molded, and stamped into specific shapes before being assembled into the final product, adding strength and durability to the accessories.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Great answer by JayDub. Amazon isn't exactly a great site for legitimate sword shopping. Look for legitimate retailers specializing in handmade swords.

- Q: How are steel coils used in the production of HVAC equipment?

- Steel coils are used in the production of HVAC equipment primarily for their heat transfer capabilities. These coils, made of high-quality steel, are essential components in the heat exchangers of HVAC systems. They help facilitate the transfer of heat between the refrigerant and the surrounding air, allowing for efficient heating or cooling. The steel coils are typically designed with fins or tubes to increase the surface area and enhance heat transfer efficiency, ensuring optimal performance and energy efficiency in HVAC units.

Send your message to us

Z17 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 98 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords