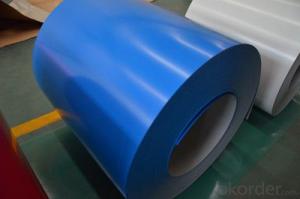

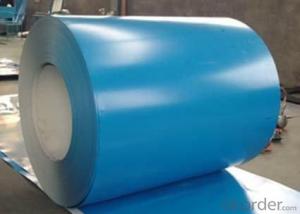

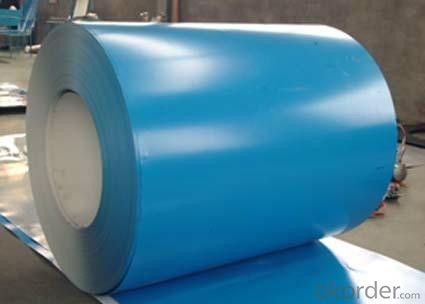

Z13 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z13 BMP Prepainted Rolled Steel Coil for Construction

Description of Z13 BMP Prepainted Rolled Steel Coil for Construction

EN 10147 Structure hot dip galvanized steel coil DX51D ,S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S450GD

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, we have very competitive price for GI CRC now

Main Feature of Z13 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance. Outdoor decking

Applications of Z13 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet as requested.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z13 BMP Prepainted Rolled Steel Coil for Construction

Product | Z13 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.0mm |

Width | 500-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-275g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle/min spangle |

ID | 508MM 610MM |

Coil weight | 10-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z13 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely, please refer below:

1. How Can I Visit your company?

Our company is located in Beijin City, China, You can fly to beijing Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample, you can for the specification you need.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 35-40days. But meanwhile we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- No. Steel does not build up static electricity by itself. Also, magnetic fields are made by moving electricity, not static electicity. The steel conducts magnetism, so it changes the earth's magnetic field near itself by conducting the field through itself. The larger effect is a magnet near a piece of steel: the compass has a magnet, and when you place it near a ferromagnetic material, it attracts. Try putting a refridgerator magnet against the fridge - it sticks because it attracts.

- Q: I know some .50 Cal BMG will do that, but what are some other cartridges ?Also, are all steel plate the same hardness ?

- You need to read in depth about steel and the many forms and recipes that can be used as well as the difference of a sabot and a FMJ round. Many factors can change the ability of a given object to resist a projectile. Angle being top of the list. Next time you walk past a Bank look at the BR window, if they have one, and note it is angled down from top to bottom. This adds to the rated strength and deflects most rounds in a direction that may assist in the round not bouncing around and hitting others in vital locations. Modern armor used on tanks includes DU. My former employer has steel that at 1/2 is as resistant to attack as 1 of the competion. There are other tricks like adding ball bearings or metal shaving to steel and cement ot break tools used to drill. They will have an effect on the ability to break a projectile as well. You are just one more looking for a short answer to a very complex issue. Armor piercing rounds have been around for some time. Sabots and DU. A .50 sabot armor piercing round may well penetrate what a standard .50BMG will not. Silk can be effective in stopping a projectile too.....you might need a thick blanket wrap.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- Yes, OK for steel. Like Mr. 357 says, with steel shot one size more open is equal to the one size tighter. So the Modified should shoot like a full choke and your improved cylinder should pattern like a modified choke. The Express model came out about the same time steel shot became prevalent and it is fine with steel shot. If I remember correctly we were working on making the data sheets for steel shot around 1988-1989. My hunting buddy and neighbor was the man who first began importing steel shot. Had to figure out a wad to use with it also. And got it Federally mandated for waterfowl hunting.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized flatbed trucks or railcars. The coils are carefully loaded onto these vehicles and secured using straps or chains to prevent any movement during transit. In some cases, shipping containers are also used to transport steel coils via cargo ships.

- Q: How are steel coils used in the production of metal ductwork?

- Steel coils are an essential component in the production of metal ductwork. These coils, typically made from high-quality steel, serve as the primary raw material for manufacturing ductwork. The process begins with the unwinding of the steel coil, which is then cut into specific lengths according to the required dimensions of the ductwork. These lengths are then shaped into the desired form using specialized machinery, such as roll formers or bending machines. The steel coils provide the necessary strength and durability to the ductwork, ensuring that it can withstand the pressure and environmental conditions it may encounter in its operational life. The coil's composition also allows for easy fabrication and customization, enabling manufacturers to create ductwork of various shapes and sizes to meet specific project requirements. Furthermore, the inherent properties of steel, such as its resistance to corrosion and fire, make it an ideal material for ductwork. Steel coils can be coated with protective layers, such as galvanized or stainless steel finishes, to enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional even in harsh environments or in the presence of corrosive substances. In summary, steel coils play a crucial role in the production of metal ductwork by providing the necessary raw material for fabrication. Their strength, durability, and customization capabilities make steel coils an indispensable component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

- Q: Are steel coils affected by temperature changes?

- Yes, steel coils are affected by temperature changes. Steel is a metallic material that expands when heated and contracts when cooled. Temperature fluctuations can cause steel coils to expand or contract, which may impact their dimensions, mechanical properties, and overall performance. It is important to consider and manage temperature changes to ensure the proper functioning and durability of steel coils.

- Q: Which of the two are better for exhaust manifolds, im guessing the stainless steel right?

- I would go with the stainless steel. I know that there was recently a study done that said that the non-stick material is slowly leaking the non-stick coating into your food. There is a problem with the copper and other metal pans as well. Slowly poisoning you throughout the years. As far as the cast iron, I am not totally sure that there are any problems with those. I haven't heard anything about them that is. I do know that cast iron gets hotter and cooks faster than the other metals. I hope I was able to help. Good luck.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they can be formed into various shapes and sizes to create the enclosure's structure. The coils are typically cut, bent, and welded together to form the walls, base, and lid of the enclosure, providing a sturdy and protective housing for electrical components.

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

- Q: With the Reduced weight of steel,wouldn't the projectile be at a much higher velocity when fired causing more damage?I mean l couldn't steel be worked to seal the bore,not damage the rifling and still cheap enough to mass produce,and be light enough to carry much more ammo.

- The bullet needs to be a bit malleable to conform to the grooves in the barrel. In an American .30 gun a .308 bullet is forced out of the gun it has to conform to the .30 bore and .308 grooves to form a tight seal. That's why lead and copper are the primary materials of the bullet. A steel bullet in a steel bore would potentially produce a pipe bomb or at least do significant damage to the bore. Also, the weight of bullets are optimized for their application with the current materials. There is no need or desire to reduce the mass of the bullet. Simply reducing mass for increased velocity can effect the terminal ballistics in all kinds of ways, but you cannot assume that damage will be higher for a variety of reasons. If nothing else the fact that the military has INCREASED the 5.56x45mm from 55gr to 62gr should be enough to doubt your claim. Also steel is about 70% the density of lead, so there would not be a major savings in mass, but aluminum is only 25% the density and it is much closer to the hardness of lead. If you really wanted a light bullet, the aluminum may be the way to go.

Send your message to us

Z13 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords