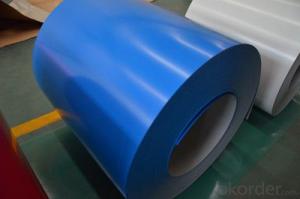

Z11 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z11 BMP Prepainted Rolled Steel Coil for Construction

Description of Z11 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z11 BMP Prepainted Rolled Steel Coil for Construction

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Z11 BMP PPGI Prepainted Rolled Steel Coil for Construction

1)Uncoiled and sheared

2)Cleaned using a caustic solution, which can remove oil/grease, dirt, and paint

3)Entry looper to revised and then annealing furnace

4)Steel is dipped into the molten zinc bath

5)Cooled in a quench tank to reduce its temperature

6)Post treatment and crimper

Specifications of Z11 BMP Prepainted Rolled Steel Coil for Construction

Product | Z11 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z11 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or attracted to magnets. When a magnetic field is applied to a steel coil, it can induce a magnetic field within the coil, causing the coil to become magnetized. This can have several effects depending on the strength and duration of the magnetic field. If the magnetic field is strong and the coil is exposed to it for a significant amount of time, it can cause the steel coil to retain some magnetism even after the magnetic field is removed. This can be problematic in certain applications where a non-magnetic material is required, as the magnetized steel coil may attract or interfere with other nearby objects. On the other hand, if the magnetic field is rapidly changing or fluctuating, it can induce electrical currents within the steel coil through electromagnetic induction. These induced currents, known as eddy currents, can generate heat within the coil, leading to energy losses and potential damage to the coil. Therefore, it is important to consider the effects of magnetic fields on steel coils in various applications. Protective measures such as shielding or demagnetizing processes may be necessary to minimize the impact of magnetic fields on steel coils when required.

- Q: What are the different methods of coil blanking for irregular shapes?

- Coil blanking for irregular shapes can be achieved through various methods. Among these methods, one commonly employed technique is laser blanking. By utilizing a high-powered laser, the shape is directly cut from the coil with exceptional precision. This method proves especially effective for intricate shapes, minimizing wastage. Another approach is water jet blanking, where a forceful stream of water mixed with abrasive particles is employed to cut the shape from the coil. Water jet blanking is particularly suitable for thicker materials or situations where heat sensitivity is a concern. Additionally, die blanking involves the utilization of a die to stamp out the desired shape from the coil. This method is frequently applied in large-scale production runs and can be automated for improved efficiency. Lastly, plasma blanking utilizes a plasma torch to cut the shape from the coil. It is commonly employed for thicker materials or situations requiring high cutting speeds. The choice of coil blanking method for irregular shapes is dependent on factors such as material thickness, shape complexity, production volume, and desired precision. Each method possesses its own advantages and limitations, necessitating careful selection to achieve optimal results.

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- I'd keep in mind whether your potential supplier is close enough to still give you good service, and provide delivery when you need it. I'd want to contact as many local companies as possible, in order to get competitive bids. Then, I'd pick the lowest cost bids that I felt would still provide the service I needed. Most decisions of this sort, in the end, are based on price.

- Q: What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel used, the manufacturing process and techniques employed, the temperature and time of the heat treatment, the level of mechanical stress and strain during rolling and cooling, and the presence of any impurities or defects in the final product.

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled with great care during transportation to prevent damage. They are usually secured with steel bands or straps to keep them in place and prevent them from shifting or rolling. Additionally, they are often placed on specialized transportation equipment, such as flatbed trailers or coil carriers, that have built-in supports to hold the coils securely. These measures help ensure that the coils remain stable and protected throughout the transportation process, minimizing the risk of damage.

- Q: Okay, I have looked all ovcer the net and it says diamonds are stronger, but why? I mean, why is diamonds used for the top equiptment rather than steel?

- Diamonds okorder

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various techniques such as visual inspection, automated systems, and magnetic particle inspection. Visual inspection involves trained personnel examining the coils for any visible defects or irregularities. Automated systems utilize cameras and sensors to detect defects and anomalies on the coil surfaces. Magnetic particle inspection, on the other hand, involves magnetizing the coil and applying magnetic particles to reveal any surface defects through the formation of visible indications. These methods ensure that steel coils meet quality standards before further processing or shipment.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger

- Q: How are steel coils used in the production of electrical transmission poles?

- The production of electrical transmission poles relies heavily on steel coils, which are crucial for their strength and durability. These coils, made from high-quality steel, are used to create the poles' main body. They are unrolled and shaped into large cylindrical sections, which are then welded together to form the structure of the pole. This manufacturing process allows for the customization of poles in terms of length, diameter, and wall thickness to meet specific transmission requirements. The utilization of steel coils guarantees that transmission poles possess the necessary structural integrity to withstand demanding conditions such as heavy electrical conductors and environmental factors like wind, ice, and seismic activities. Steel, known for its high strength-to-weight ratio, is an ideal material for these poles as it provides the required strength while keeping the overall weight of the pole relatively low. Furthermore, steel coils also serve in the fabrication of flanges and brackets that attach to the poles. These components are essential for securing and supporting electrical conductors and insulators on the poles. By using steel coils, flanges and brackets can be manufactured with precise dimensions and strength, ensuring a secure and reliable connection between the electrical components and the transmission poles. Apart from their structural advantages, steel coils also offer excellent resistance to corrosion. This characteristic is particularly important for electrical transmission poles, which are exposed to harsh weather conditions and corrosive environments. To enhance the lifespan of the poles, steel coils are typically coated with protective layers such as zinc or epoxy to prevent rust and corrosion. To summarize, steel coils play a vital role in the production of electrical transmission poles. They are used to fabricate the main body of the poles, as well as the flanges and brackets that secure the electrical components. With their high strength, durability, and corrosion resistance, steel coils ensure that transmission poles can safely and reliably support electrical conductors for efficient electricity transmission.

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

Send your message to us

Z11 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords