Z19 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

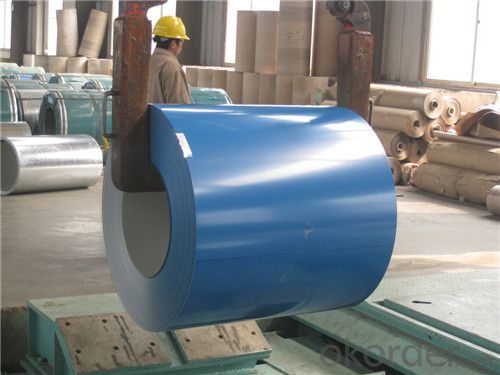

Structure of Z19 BMP Prepainted Rolled Steel Coil for Construction

Description of Z19 BMP Prepainted Rolled Steel Coil for Construction

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z19 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z19 BMP PPGI Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z19 BMP Prepainted Rolled Steel Coil for Construction

Product | Z19 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z19 BMP Prepainted Rolled Steel Coil for Construction

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are steel coils?

- Steel coils are large, flat sheets of steel that have been rolled into a circular shape. They are commonly used in various industries, including automotive, construction, and manufacturing, for purposes such as making pipes, tubes, and sheet metal products.

- Q: How are steel coils recycled?

- Steel coils are typically recycled by first being collected and transported to a recycling facility. At the facility, the coils are unpacked and sorted based on their type and quality. Any contaminants, such as oil or paint, are removed through a cleaning process. The coils are then shredded into smaller pieces and melted in a furnace. Once melted, impurities are skimmed off the top, and the molten steel is poured into molds to form new coils or other steel products. This process helps conserve resources and reduce the need for mining new materials.

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums by being cut into sheets and then rolled into cylindrical shapes, which form the body of the drum. The coils provide the necessary strength and durability required for the drums to hold and transport various materials safely.

- Q: What are the different methods of forming steel coils?

- Steel coils can be formed using several methods, depending on their specific requirements and applications. These methods comprise hot rolling, cold rolling, and continuous casting. The most commonly used method for forming steel coils is hot rolling. This involves heating the steel billet or ingot to high temperatures and passing it between a series of rollers to reduce its thickness and shape it into a coil. Typically, this process is carried out above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. On the other hand, cold rolling is performed at or near room temperature. It entails passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often utilized to produce steel coils with precise dimensions and excellent surface finish. Additionally, it can enhance the strength and hardness of the steel. Another method for forming steel coils is continuous casting. This involves pouring molten steel into a continuous casting machine, where it solidifies into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, including improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These processes encompass pickling, annealing, and coating. Pickling is used to remove any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which improves its ductility and reduces internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. To summarize, steel coils can be formed using different methods such as hot rolling, cold rolling, and continuous casting. Each method offers distinct advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes like pickling, annealing, and coating are employed to further enhance the quality and performance of the steel coils.

- Q: What are the different types of steel coil cutting tools?

- There are several types of steel coil cutting tools, including slitting shears, rotary slitters, flying shears, and laser cutters. Each tool is designed to cut steel coils into specific shapes and dimensions, depending on the desired end product.

- Q: What are the different methods of coil cutting for steel coils?

- There are several methods of coil cutting for steel coils, each with its own advantages and suitability for different applications. Here are some of the common methods: 1. Slitting: Slitting is the most commonly used method for coil cutting. It involves passing the steel coil through a set of rotating circular blades that cut the coil into narrower strips. This method is suitable for producing narrow width strips with precise dimensions. 2. Shearing: Shearing is another method used for coil cutting, especially for thicker gauge coils. It involves using a straight blade to cut the coil along a straight line. Shearing is suitable for producing larger width strips and is often used for heavier gauge steel coils. 3. Laser Cutting: Laser cutting utilizes a high-powered laser beam to cut through the steel coil. This method offers a high degree of precision and can be used to cut complex shapes and patterns. Laser cutting is often used for specialized applications where accuracy and fine details are crucial. 4. Waterjet Cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can be used for cutting various materials, including steel. Waterjet cutting is suitable for producing clean and precise cuts without heat-affected zones. 5. Plasma Cutting: Plasma cutting utilizes a high-temperature plasma arc to melt through the steel coil. This method is efficient and can be used for cutting thick gauges of steel. Plasma cutting can achieve high cutting speeds, making it suitable for industrial applications. 6. Guillotine Cutting: Guillotine cutting involves using a guillotine-like mechanism to cut through the steel coil. The coil is placed on a table, and a blade descends vertically to cut through it. Guillotine cutting is suitable for producing straight and accurate cuts with minimal burrs. The choice of coil cutting method depends on various factors such as the desired width and thickness of the strips, required precision, production volume, and the specific application. It is important to consider these factors and consult with experts to determine the most suitable coil cutting method for a particular steel coil.

- Q: How are steel coils used in the production of metal shelving?

- Steel coils are used in the production of metal shelving by being processed and formed into the desired shape and size. The coils are unwound and then either cut or shaped using various techniques such as bending, welding, and punching. This allows for the creation of sturdy and durable shelves that can hold heavy loads.

- Q: I'm wondering if steel casings are bad for a 1911. I know that an AK-47 will eat up steel casings all day long, but steel casings are bad for, and can be hard on an AR-15. I only have brass for my AR and that will never change. I'm curious as to how a 1911 fairs with steel casings. Is it bad for the gun or does it not matter? I'm asking because steel cased rounds seem to be the only readily available ammo these days. Thanks

- steel casings go back to the early 1900's for 1911's. Most guns were always able to handle them and most of that has carried on. I would think glocks are a no no for steel for longevity but in the caribbean we have mainly steel casings and that's all we use. the 1911 is probably the most popular hand gun down there. I own one, and FM. Over 1000 rounds so far in her between me and my dad (previous owner)

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers employ a variety of strategies and techniques to effectively manage their inventory, optimize production, minimize costs, and meet customer demands. The following are some commonly used practices: 1. Accurate demand forecasting: Steel coil manufacturers analyze market trends, historical sales data, and customer orders to accurately forecast future demand. This enables them to determine the necessary inventory levels and plan production accordingly. 2. Just-in-time (JIT) inventory: Many steel coil manufacturers adopt the JIT inventory system, which involves maintaining minimal inventory levels by receiving raw materials shortly before production and delivering finished goods immediately after. This approach reduces carrying costs and mitigates the risk of excess inventory. 3. Collaborating with suppliers: Effective inventory management relies on close collaboration with suppliers. Steel coil manufacturers work closely with their suppliers to ensure timely delivery of raw materials, monitor quality, and maintain a consistent supply. Regular communication and sharing of production forecasts help suppliers plan their inventory accordingly. 4. Safety stock: Steel coil manufacturers maintain a certain level of safety stock to account for unpredictable fluctuations in demand, disruptions in the supply chain, or delays in raw material deliveries. This acts as a buffer to prevent stockouts and maintain customer satisfaction. 5. Implementing inventory control systems: Steel coil manufacturers utilize modern inventory control systems, such as Enterprise Resource Planning (ERP) software, to track inventory levels, monitor stock movements, and automate various inventory management processes. These systems provide real-time data and analytics, facilitating better decision-making and improving inventory accuracy. 6. Streamlining production planning: Steel coil manufacturers optimize production planning to minimize inventory holding costs. They schedule production based on demand forecasts, prioritize orders, and strive for efficient production runs to reduce setup times and material waste. 7. Regular inventory analysis: Steel coil manufacturers regularly analyze their inventory data to identify slow-moving items, obsolete stock, or excess inventory. By identifying such issues, they can take corrective actions such as offering discounts, initiating sales promotions, or adjusting production schedules to prevent inventory buildup. In conclusion, effective inventory management is crucial for steel coil manufacturers to maintain a lean and efficient operation while meeting customer demands. By utilizing these strategies, manufacturers can strike a balance between supply and demand, reduce costs, and enhance customer satisfaction.

- Q: which elements are alloyed to make stainless steel?A Fe, CB Fe, MnC Fe, NiD Fe, CrE Fe, Cr, Ni

- E. Stainless steel is mainly comprised of Cr and Ni. Steel is an alloy composed mainly of iron. On a side note, Carbon is not really in stainless steel and it is only less than .1%

Send your message to us

Z19 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords