china reliable PVC Coated/Galvanized/Stainless Steel Welded Wire Mesh manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

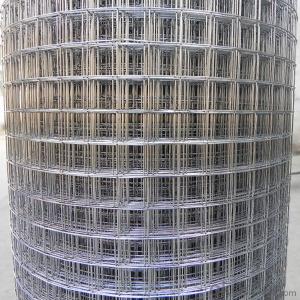

china reliable pvc coated/galvanized/stainless steel Welded Wire Mesh manufacturer

1. Welded Wire Mesh Description:

Welded wire mesh is made from stainless steel wire or galvanized wire, which shows good corrosion-resistance and oxidation-resistance, widely used for poultry houses, egg baskets, runway enclosures, draining racks, porch guards, rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

2.Main Features of the Welded Wire Mesh:

smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster .The mesh doesn’t come loose even if cut in parts or being exerted force on parts .Compared with general iron wire ,the products are better in respects of anti-corrosive and anti-rust.

3.Welded Wire Mesh Images

4.Welded Wire Mesh Specification

Specification List of Galvanized Welded Wire Mesh: | ||

Opening | Wire Diameter | |

In inch | In metric unit(mm) | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

Technical Note: 1.Standard roll length: 30m;width: 0.5m to 1.8m 2.Special sizes available at request | ||

Special sizes are also available.

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Australia.

(2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel gratings and stair treads available?

- There are several different types of steel gratings and stair treads available, including welded steel gratings, press-locked steel gratings, and swage-locked steel gratings. Welded steel gratings are made by welding steel bars together to form a strong and durable grid structure. Press-locked steel gratings have interlocking sections that are mechanically locked together, providing a secure and stable surface. Swage-locked steel gratings are manufactured by permanently attaching cross bars to bearing bars through a swaging process, resulting in a high-strength and aesthetically pleasing grating. Stair treads can be customized to fit different applications, and they often come with various nosing options for added safety and stability.

- Q: What are the common types of steel products used in the fitness and sports industry?

- Common types of steel products used in the fitness and sports industry include barbells, dumbbells, weight plates, kettlebells, weight machines, exercise bikes, and sports equipment such as goal posts and basketball hoops.

- Q: What are the different types of steel springs and their applications?

- There are various types of steel springs used in different applications. Some common types include compression springs, used in automotive suspension systems and industrial machinery; extension springs, used in garage doors and trampolines; torsion springs, used in clothespins and door hinges; and flat springs, used in electronics and appliances. These springs differ in their design and shape to provide specific functions and meet the requirements of various industries.

- Q: What are the different types of steel chains and their uses?

- There are several types of steel chains, including welded chains, roller chains, and stainless steel chains. Welded chains are commonly used for general purposes, such as securing equipment and lifting heavy loads. Roller chains, on the other hand, are designed for power transmission applications, often found in bicycles, motorcycles, and industrial machinery. Stainless steel chains, known for their corrosion resistance, are commonly used in marine environments, food processing, and medical equipment. Each type of steel chain has its own specific uses depending on the industry and application requirements.

- Q: How do steel products contribute to the defense and military sector?

- Steel products play a crucial role in the defense and military sector as they are used in the production of various equipment and structures. Steel is known for its strength, durability, and resistance to damage, making it an ideal material for manufacturing weapons, vehicles, submarines, aircraft carriers, and other military hardware. Additionally, steel is used in constructing military infrastructure such as airfields, barracks, and command centers, providing the necessary protection and support for military operations. Overall, steel products contribute significantly to the defense and military sector by ensuring the reliability, safety, and effectiveness of various defense systems and infrastructure.

- Q: How are steel forgings used in the production of power generation equipment?

- Steel forgings are used in the production of power generation equipment due to their strength, durability, and ability to withstand high temperatures and pressures. They are commonly used in critical components such as turbine blades, rotors, and shafts, ensuring the reliable and efficient operation of power plants. The forging process enhances the structural integrity of the steel, making it resistant to fatigue and wear, thereby extending the lifespan and performance of the equipment.

- Q: What are the different types of steel fasteners and their applications?

- There are several different types of steel fasteners commonly used in various applications. Some of the most common types include bolts, screws, nuts, and washers. Bolts are threaded fasteners that are used to join two or more components together. They come in different sizes and strengths, making them suitable for a wide range of applications such as construction, automotive, and machinery. Screws are similar to bolts but have pointed ends and are typically used to secure objects to a surface or to hold components together. Nuts are threaded fasteners that are used in conjunction with bolts to create a secure joint. They provide additional stability and can be easily tightened or loosened. Washers are flat, disk-shaped fasteners that are placed between a nut or bolt head and the surface of the material being fastened. They help distribute the load and prevent damage to the material. Overall, steel fasteners are essential components used in various industries for their strength, durability, and versatility.

- Q: What are the advantages of using steel in the manufacturing of tanks and vessels?

- There are several advantages of using steel in the manufacturing of tanks and vessels. Firstly, steel is known for its exceptional strength and durability, making it capable of withstanding high pressures and harsh environmental conditions. Secondly, steel is resistant to corrosion, which is crucial for tanks and vessels that come into contact with different liquids and chemicals. Additionally, steel offers versatility in terms of shape and size, allowing for customized designs to meet specific requirements. Lastly, steel is a sustainable and recyclable material, making it a cost-effective and environmentally friendly choice for tank and vessel manufacturing.

- Q: How is steel tubing manufactured?

- Steel tubing is manufactured through a process called tube making, which involves various steps such as heating, welding, and shaping steel strips or plates into a cylindrical form. These strips are first heated and then passed through a series of rollers to form a continuous tube. The edges are then welded together, and the tube is further shaped and sized using additional rollers. Finally, the tube is cut to the desired length and undergoes various finishing processes to meet the required specifications and quality standards.

- Q: What are the different types of steel sheets and their uses in the automotive industry?

- There are various types of steel sheets used in the automotive industry, including hot-rolled, cold-rolled, galvanized, and advanced high-strength steel (AHSS) sheets. Hot-rolled steel sheets are commonly used for structural components due to their high strength and durability. Cold-rolled steel sheets, on the other hand, are preferred for body panels and other parts requiring excellent surface finish and dimensional accuracy. Galvanized steel sheets are coated with a layer of zinc, making them highly resistant to corrosion and ideal for automotive body panels. Lastly, AHSS sheets are specifically designed to provide superior strength while reducing weight, thereby enhancing fuel efficiency and safety in vehicles.

Send your message to us

china reliable PVC Coated/Galvanized/Stainless Steel Welded Wire Mesh manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords