Steel Sheet Pile Coner Pile Box Pile WRG

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Sheet Pile Coner Pile Box Pile WRG:

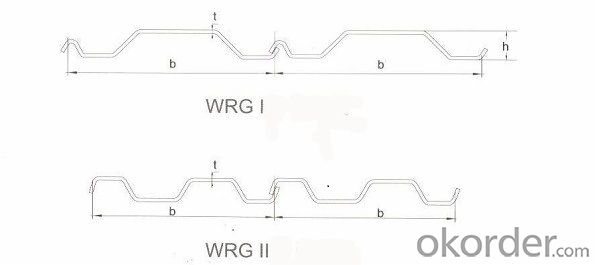

Profile | Width | Thick ness | Height | Weight per pile

| Weight per wall | Section modulus | Moment of inertia

| Radius of Gyration |

| mm | mm | mm | Kg/m | Kg/m2 | Cm3/m | cm4/m | cm |

WRGI-1 | 750 | 6 | 95 | 42.4 | 56.6 | 202 | 975 | 3.7 |

WRGI-2 | 750 | 7 | 96 | 49.6 | 66.1 | 234 | 1139 | 3.7 |

WRGI-3 | 750 | 8 | 97 | 56.8 | 75.7 | 266 | 1304 | 3.7 |

|

|

|

|

|

|

|

|

|

WRGII-1 | 650 | 6 | 80 | 40.5 | 62.4 | 190 | 758 | 3.1 |

WRGII-2 | 650 | 8 | 82 | 53.9 | 83.0 | 247 | 1013 | 3.1 |

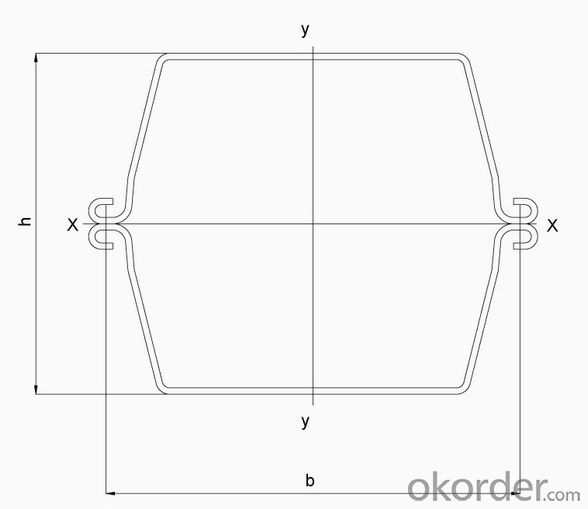

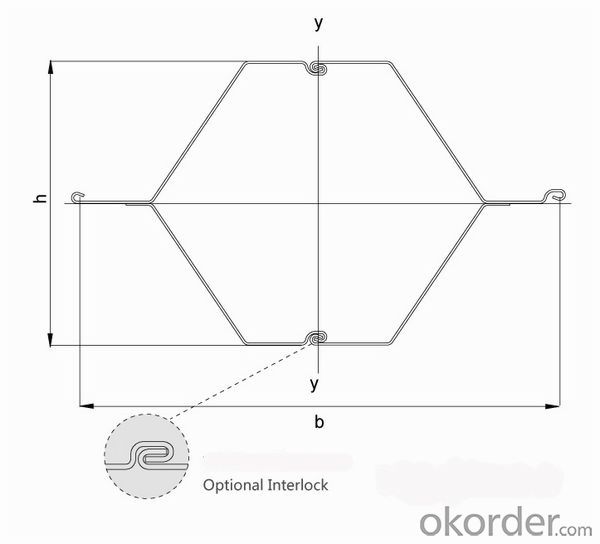

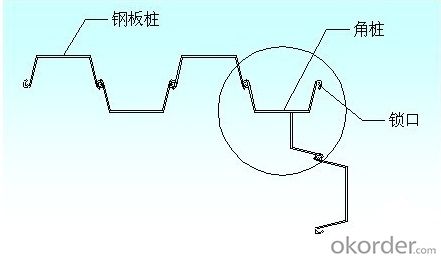

Ø Corner sheep pile is a newly developed type produced by rolling, which eliminate the need for welding and other fabrication processes, and is far lighter in weight

Ø The corner interlocking sections have been improved in shape to prevent loosening

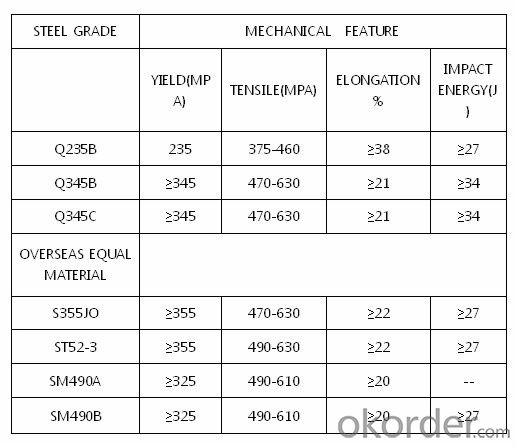

Steel Grade for Sheet Pile

Usage and Applications of Steel Sheet Pile Coner Pile Box Pile WRG:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: How is steel used in the production of marine equipment and vessels?

- Steel is used extensively in the production of marine equipment and vessels due to its strength, durability, and corrosion resistance. It is used to construct the hulls, decks, and superstructures of ships, as well as various components such as propeller shafts, rudders, and bulkheads. Steel's high tensile strength allows for the construction of large, sturdy vessels capable of withstanding harsh marine environments and rough seas. The corrosion resistance properties of steel are crucial in preventing damage from constant exposure to saltwater, ensuring the longevity and reliability of marine equipment and vessels.

- Q: How do steel products contribute to the renewable energy sector?

- Steel products contribute to the renewable energy sector in various ways. Firstly, steel is used in the manufacturing of wind turbines, providing structural integrity and support for the blades and towers. Additionally, steel is used in the construction of solar panels, ensuring durability and longevity. Furthermore, steel is utilized in the transmission and distribution infrastructure for renewable energy, such as power lines and grid systems. Overall, steel products play a vital role in the development, installation, and maintenance of renewable energy technologies, enabling the sector to flourish and reduce reliance on fossil fuels.

- Q: How does steel sheet metal bending and forming work?

- Steel sheet metal bending and forming involve applying force to a sheet of steel to shape it into a desired form, such as a bend, curve, or complex shape. This process is typically done using specialized machines called press brakes, which have a V-shaped die and a punch. The sheet metal is placed between the die and punch, and force is applied to the punch, causing the metal to deform and take the shape of the die. The amount of force, angle of the die, and other variables determine the final shape and accuracy of the bending process.

- Q: What is the role of steel in the manufacturing of railway tracks?

- Steel plays a crucial role in the manufacturing of railway tracks as it provides the necessary strength, durability, and resilience to withstand the heavy loads and constant wear and tear of trains. It is used to construct the rails, which provide a smooth and stable surface for train wheels to run on. Steel's high tensile strength allows for longer and continuous tracks without the need for frequent expansion joints, ensuring a safer and more efficient railway system.

- Q: What are the different types of steel scaffolding systems?

- There are several different types of steel scaffolding systems, including tube and coupler scaffolding, frame scaffolding, modular scaffolding, and suspended scaffolding.

- Q: What are the different types of steel nails and their applications?

- There are several types of steel nails available, each with specific applications. Common types include common nails, finishing nails, roofing nails, and concrete nails. Common nails are versatile and widely used for general construction and framing. Finishing nails have smaller heads and are used for delicate woodworking projects where the nail head needs to be concealed. Roofing nails have larger heads and are designed to secure shingles and other roofing materials. Concrete nails are hardened and used specifically for driving into concrete or masonry.

- Q: What are the different types of steel coatings and finishes available for steel products?

- There are several types of steel coatings and finishes available for steel products. Some common options include galvanized coatings, which provide corrosion resistance through a layer of zinc; powder coatings, which are applied as a dry powder and then cured to form a durable finish; and paint coatings, which can be applied in various colors and provide both protection and aesthetic appeal. Additionally, there are specialty coatings such as chrome plating, nickel plating, and epoxy coatings, each offering unique properties and benefits for specific applications.

- Q: What are the different types of steel gratings and their applications?

- There are several types of steel gratings that serve different purposes and applications. These include welded steel gratings, press-locked steel gratings, riveted steel gratings, and heavy-duty steel gratings. Welded steel gratings are commonly used in industrial platforms, walkways, and stair treads due to their strong and durable construction. Press-locked steel gratings are versatile and ideal for architectural applications like facades, fences, and sunshades. Riveted steel gratings are suitable for heavy-load areas such as bridges and vehicle ramps, as they offer high strength and stability. Heavy-duty steel gratings are designed for extreme conditions and heavy loads, making them perfect for areas like airports, docks, and industrial plants. These gratings provide superior strength and durability to withstand intense pressure and impact. Overall, the different types of steel gratings cater to various industry requirements, ensuring safety, stability, and functionality in a wide range of applications.

- Q: What are the common types of steel products used in the textile industry?

- The common types of steel products used in the textile industry include steel wires, steel needles, steel pins, and steel hooks. These steel products are essential for various textile processes such as weaving, sewing, and fabric production.

- Q: What are the different types of steel wire mesh products?

- There are several types of steel wire mesh products, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Each type has its own unique characteristics and applications. Welded wire mesh is made by welding individual wires together to create a strong and durable mesh panel. Woven wire mesh is created by weaving individual wires together in an interlocking pattern, providing flexibility and strength. Expanded metal mesh is produced by cutting and stretching a metal sheet, resulting in a diamond-shaped pattern with open areas. Perforated metal mesh is made by punching holes in a metal sheet, offering various hole sizes and patterns for different purposes.

Send your message to us

Steel Sheet Pile Coner Pile Box Pile WRG

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords