L/S profile Steel Sheet Pile WRL WRS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of L/S profile Steel Sheet Pile WRL WRS:

L Profile sheet piles

Profile

| Dimension | Mass | Moment of Inertia | Elastic section Modulus | |||

Width B | Height H | Thickness T | Per Pile

| Per wall

| |||

| mm | mm | mm | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRL1.5 | 700 | 100 | 3.0 | 21.4 | 30.6 | 724 | 145 |

WRL2 | 700 | 150 | 3.0 | 22.9 | 32.7 | 1674 | 223 |

WRl3 | 700 | 150 | 4.5 | 35.0 | 50.0 | 2469 | 329 |

WRL4 | 700 | 180 | 5.0 | 40.4 | 57.7 | 3979 | 442 |

WRL5 | 700 | 180 | 6.5 | 52.7 | 75.3 | 5094 | 566 |

WRL6 | 700 | 180 | 7.0 | 57.1 | 81.6 | 5458 | 606 |

S Profile sheet piles

Profile

| Dimension | Mass | Moment of Inertia | Elastic section Modulus | |||

Width B | Height H | Thickness T | Per Pile

| Per wall

| |||

| mm | mm | mm | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRS4 | 600 | 260 | 3.5 | 31.2 | 41.7 | 5528 | 425 |

WRS5 | 600 | 260 | 4.0 | 36.6 | 48.8 | 6703 | 516 |

WRS6 | 700 | 260 | 5.0 | 45.3 | 57.7 | 7899 | 608 |

WRS8 | 700 | 320 | 5.5 | 53.0 | 70.7 | 12987 | 812 |

WRS9 | 700 | 320 | 6.5 | 62.6 | 83.4 | 15225 | 952 |

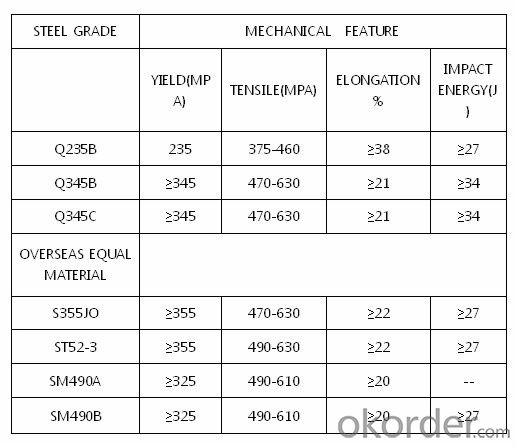

Steel Grade for Sheet Pile

Usage and Applications of L/S profile Steel Sheet Pile WRL WRS:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and cost-effectiveness. It is used to create the main body of the exhaust system, connecting the engine to the tailpipe. The steel tubing is responsible for carrying the hot exhaust gases away from the engine, preventing damage to other components and reducing noise. Additionally, steel tubing allows for the installation of catalytic converters and mufflers, which help reduce emissions and control noise levels. Overall, steel tubing plays a crucial role in ensuring the functionality and performance of automobile exhaust systems.

- Q: How do steel products contribute to the recycling industry?

- Steel products contribute to the recycling industry in various ways. Firstly, steel is one of the most recycled materials globally, with a high recycling rate of around 90%. The recycling process of steel products helps conserve natural resources and reduces the need for mining raw materials, thereby minimizing the environmental impact. Secondly, recycling steel products saves energy as it requires less energy to recycle steel compared to producing it from scratch. Additionally, the steel recycling industry creates job opportunities and stimulates economic growth. Overall, steel products play a vital role in the recycling industry, promoting sustainability and resource efficiency.

- Q: What are the different types of steel clamps and their uses?

- There are several types of steel clamps with various uses. Some common types include C-clamps, bar clamps, pipe clamps, and spring clamps. C-clamps are versatile and have a wide opening, making them suitable for general woodworking and metalworking tasks. Bar clamps are longer and can apply even pressure across a larger area, ideal for securing large pieces during glue-ups. Pipe clamps are designed to hold together pipes and are commonly used in plumbing and construction projects. Spring clamps are smaller and lighter, often used for temporary or light-duty applications like holding down a tarp or securing a workpiece temporarily.

- Q: What are the different types of steel wire and cables available?

- There are several different types of steel wire and cables available, including galvanized steel wire, stainless steel wire, carbon steel wire, and alloy steel wire. Each type has its own unique properties and applications, making them suitable for various industries such as construction, automotive, and telecommunications.

- Q: How is steel used in the manufacturing of water treatment systems?

- Steel is commonly used in the manufacturing of water treatment systems due to its durability, strength, and resistance to corrosion. It is often used to construct tanks, pipes, and other components that come into contact with water, ensuring the system's longevity and reliability.

- Q: What is the role of steel in the manufacturing of railway tracks?

- Steel plays a crucial role in the manufacturing of railway tracks as it is the primary material used for the rails. Steel's high strength, durability, and resistance to wear and deformation make it ideal for withstanding heavy loads, extreme weather conditions, and continuous train traffic. The use of steel ensures the tracks remain stable, safe, and capable of supporting the weight of trains over long distances, contributing to the efficiency and reliability of the railway system.

- Q: What are the different types of steel sheet and their uses?

- There are several types of steel sheets available, each with distinct properties and uses. Some common types include hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel. Hot-rolled steel sheets are often used in construction and manufacturing due to their strength and durability. Cold-rolled steel sheets, on the other hand, are smoother and have tighter tolerances, making them suitable for applications requiring precise dimensions. Galvanized steel sheets have a protective zinc coating, making them resistant to corrosion, and are commonly used in outdoor structures or for automotive parts. Stainless steel sheets are known for their resistance to corrosion and high temperature, making them ideal for applications in food processing, medical equipment, and chemical industries. Overall, the choice of steel sheet type depends on the specific requirements and intended use of the product.

- Q: What are the different types of steel wires and their uses?

- There are several types of steel wires, including carbon steel wire, stainless steel wire, and galvanized steel wire. Carbon steel wire is commonly used for general-purpose applications such as fencing, construction, and automotive manufacturing. Stainless steel wire, known for its corrosion resistance, is often used in industries like aerospace, medical equipment, and food processing. Galvanized steel wire is coated with zinc to enhance its corrosion resistance and is commonly used for agricultural purposes, wire mesh, and electrical applications.

- Q: How are steel sheets used in roofing and cladding systems?

- Steel sheets are commonly used in roofing and cladding systems due to their durability, strength, and resistance to harsh weather conditions. These sheets are installed as a protective layer over the roof or walls of a building, providing a sturdy barrier against external elements such as rain, wind, and sunlight. Steel sheets are easy to install, lightweight, and can be fabricated into various shapes and sizes to meet specific design requirements. Additionally, they offer excellent fire resistance, longevity, and require minimal maintenance, making them a popular choice for roofing and cladding applications.

- Q: What are the different types of steel bollards and barriers available?

- There are several types of steel bollards and barriers available, including fixed bollards, removable bollards, collapsible bollards, and automatic retractable bollards. Fixed bollards are permanently installed and provide a strong physical barrier. Removable bollards can be easily taken out when needed and offer flexibility in traffic control. Collapsible bollards can be folded down to allow temporary vehicle access. Automatic retractable bollards can be controlled electronically and are often used in high-security areas.

Send your message to us

L/S profile Steel Sheet Pile WRL WRS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords