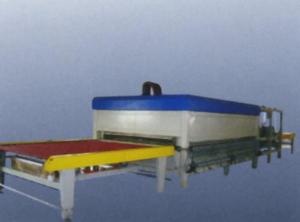

YR-6133 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

By digesting advanced technology abroad, combined with our R & D and innovation, the working performance of it can reach same level of best products of same type, with compact structure and high strength of machinery, and adopting bevel gear to transmit and stable travel in lifting & descending and X,Y axis, without vibration and having reliable performance. These machine adopts PLC and human interface control,with high working efficiency and low labor cost. Its features and functions are as below:

1. Controlled by PLC, imported from Japan.

2. Equip Germany vacuum system

3. Move with Linear Guide.

4. work automatically with hadraulic system, easy to operate the machine by computer.

5. The machine can know the opsition of the glass sheet automatically, and transfer the sheet to the cutting position by the roller.

2. Technical parameter:

Table top size: 4200×2800mm

Table top height: 900±30mm

Quantity of air fan: 1piece

(Independent switch control )

3. Main components

Table top surface: fiber and woolen felt

Table top: HDF

Bar:2pcs horizontal level

1pcs vertical level

YR-6133 glass breaking machine

1. Technical parameter:

Table top size: 6100×3300mm

Table top height: 900±30mm

Quantity of air fan: 2piece

(Independent switch control )

Main components

Table top surface: fiber and woolen felt Table top: HDF

Bar:3pcs horizontal level 1pcs vertical level

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode (automation and manual)

11) Operation screen: Color LCD touch screen interface

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

8. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kinds of equipment are there in FRP production facilities?

- Cutting equipment -- cutting dry fiberglass fabric or prepreg to the desired shape.Forming heating equipment - generally divided into two parts: forming die and heating curing furnace.

- Q: What kind of equipment does the toughened glass production line include?

- A tempering furnace is needed, but the price is not cheap

- Q: What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- Aluminum Alloy doors and windows equipment sawing aluminum section glass bead saw corner cutting saw automatic (semi-automatic) heavy angle automatic cutting machine (CNC / digital) numerical control double head cutting saw heavy (efficient) single head cutting saw (NC) aluminum profile cutting machine of 45 aluminum doors and windows of arbitrary angle precision CNC double head cutting saw group. NC four head angle machine (vertical and horizontal) multi angle machine end milling head profile milling machine (Dan Tou) row curtain wall Tenoing machine milling machine milling machine (five knife) stamping press bending machine hardware punch hollow glass equipment vertical insulating glass production line of glass washing machine automatic production line automatic pressure plate rolling production line of vertical insulating glass production line glass washing machine horizontal hot press laminating horizontal cold roller press hollow glass auxiliary equipment of glass washing machine horizontal hot press and horizontal Sheet cold roll press curtain wall processing equipment, planer groove, drilling equipment, aluminum curtain wall composite board, planer slot machine

- Q: How much do you charge for a set of insulating glass processing equipment?

- Mainly processing aluminum strip type of insulating glass; 3 cleaning dryer and hot melt adhesive machine, mainly processing hot-melt adhesive hollow glass.

- Q: How much will it cost to machine ordinary glass into toughened glass? Where can I buy it?

- The imported Finland produces millions to tens of millions of people. Generally, domestic products can meet the requirements of production. Tens of millions of dollars are available, mainly depending on what you do and what specifications you want.

- Q: How is glass produced? How much does it cost to open a glass plant and what equipment do we need?

- What kind of glass factory do you prefer? A toughened glass factory, an ordinary glass factory and so on. The investment in the toughened glass factory is much lower than that of the ordinary glass factory

- Q: How much is the equipment for toughened glass production?

- Normally want to buy bilateral line milling machine, the price is unknown, probably need yiershiwan; then working capital, inventory, rent, utilities, wages etc.. If these are entirely new investments, about 250-300.

- Q: How do you make plexiglass?

- With a file or emery cloth for coarse grinding, chamfering and rounding with fine gauze and then polished, finally with ordinary toothpaste with a soft cloth polishing line. When grinding, pay attention to protect, good to hurt the front.

- Q: What are the main equipments for making insulating glass? How much would a whole set of funds be?

- Hot melt adhesive hollow glass is also only two pieces of equipment: washing machine, hot melt glue machine is about more than 20000

- Q: Can glass fiber reinforced plastics be machined with high precision?

- Matters needing attention(1) because the mechanical properties of glass fiber products are brittle and brittle, it is difficult to clamp. The clamping force causes the workpiece to deform or block the workpiece, and the excessive force will cause the workpiece to fly off.(2) because of the glass fiber heat is relatively poor, linear expansion into relatively large, the workpiece is easy to deform, the size is more difficult to control.(3) the best data can be obtained only through process experiments.

Send your message to us

YR-6133 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches