2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

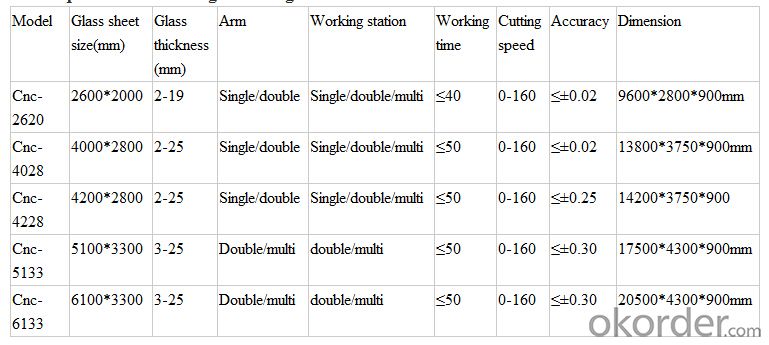

2. Technical parameter:

3. Main components

a, Turning angle: adjustable, from 95 to 98 degree.

b, Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

c, Induction system: two sets of photoelectric sensors to ensure safety operation.

d, Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

e, Suction system: introduced double layer suction, strong absorption.

f, Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

g, Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

h, Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

i, Operation mode: The machine has two kinds controlling mode(automation and manual)

j, Operation screen: Color LCD screen interface

k, Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: Can plexiglass be machined with CNC milling machines?

- Tolerable。What exactly do you do, such as engraving, embossing, or simply cutting plexiglass?.

- Q: What are the equipment for making glass?

- The main difference is that this piece of molding, specifically what kind of glass, the use of major equipment and ancillary equipment are more, you specifically introduced, you can exchange.

- Q: What are the processing methods of organic glass?

- Hot bending: shape shapes of organic glass through high temperatures.(1) hot bending method:Clamp the heating with a flat fixture.Hot air gun: heating is not uniform, easy residual uneven cooling caused by thermal stress, days after the easy deformation.Constant temperature furnace: the temperature is relatively average, and the temperature is more uniform when cooled.(2) the temperature and time of setting and tempering of plexiglass after heating:Generally use PMMA, 65-70 degrees, 3-5 hours (hot air heating method)Heat resistant with PMMA, 75-80 degrees, 3-5 hours (hot air heating method)Note: this treatment is to eliminate the residual molding forming residual stress, improve the size stability after the change; mechanical properties; improve the dimensional accuracy, or reduce the deformation.

- Q: Problems in the mechanical processing of glass fiber reinforced plastics

- I think it is of little significance to use cutting fluid when machining frp. Because the heat of cutting is not enough, air cooling can satisfy. But there will be an environmental problem - dust flying, which is harmful to people when they are sucked in. Therefore, we used to buy a set of industrial vacuum cleaners, processing machine parts (work stations) partially closed, operators with industrial masks, quite troublesome. Have also tried to dial a special machine (milling machine) to make glass fiber reinforced plastic products. With coolant, the chip separation mechanism is specially made, which is similar to the filter of grinding machine.

- Q: Which equipment does the glass mirror need?

- Some equipment needed for processing glass mirror:Cutting tools, glass knife (blade), square, tape, cut = = if the conditions can be automatic cutting machine on a (about 150 thousand on the I)

- Q: How is glass produced? How much does it cost to open a glass plant and what equipment do we need?

- Don't you save it also engage in mechanical mech workshop equipment is not so expensive to make money

- Q: What kind of cutting fluid is used in organic glass processing?

- SCC790 glass cutting fluid is a high-grade, glass and ceramic special synthetic glass grinding fluid, diluted with water to form a clear, transparent yellow solution.

- Q: Installation and debugging of insulating glass processing equipment

- (7) clean the water tank before watering the tank.(8) after installation and adjustment, test in accordance with the order of operation as specified in this specification.(9) clean the minimum size glass, do not place parallel with the roll.

- Q: How do you make plexiglass?

- With a file or emery cloth for coarse grinding, chamfering and rounding with fine gauze and then polished, finally with ordinary toothpaste with a soft cloth polishing line. When grinding, pay attention to protect, good to hurt the front.

- Q: What processing machines do glass patches use?

- A lamp; semi-finished products processing, cutting grinding and polishing. Two. Hot melt glass molding. Equipment is not complicated, there must be technology

Send your message to us

2015 Full and Semi automatic glass cutting machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches