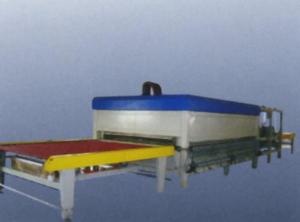

YR-2520 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Description of Automatic Glass Loading Machine

Glass Cutting Machine is Introduced in European advanced technology ,using the lasted technology and processing craft ,high-precision rack slide roll servo motor and starting components ,to achieve long-term precision and stability ,to achieve the effects of processing fast.Glass Cutting Machine adopt the lasted imported control system ,run faster ,higher security ,efficient and stable.Glass Cutting Machine has a lot of functions of photoelectric positioning ,accurate and easy to operate ,save more power.

1. The advanced mechanical structure ensures its stability and durability.

2. By importing Italy OPTIMA cutting and optimizing software and Italy TECNOS PLC, it features strengthened security, faster speed, more accuracy, easy operation, higher utilization rate, better stability, full functionality and more laborsaving.

3. Compatible to major ERP and office optimization system.

4. Easy to operate and labor saving.

2. Technical parameter:

2.1 Equipment System : main frame/ running system/ transfer system/vacuum adsorption system/mechanical turning system/high and low pressure control system/program control system

2.2 Mechanical components:

1) turning wheel chain: high precision reinforced type

2) transfer idler wheel : PU

3) vacuum suction cup: double absorption structure

4) transfer/turning motor: Taiwan CPG motor

5) vacuum pump: PUXU( Sino-Germany)

2.3 Electric elements.

1) PLC controller: Delta

2) Transducer: Delta

3) Proximity switch: Swiss ELCO

4) Control cable: High-flexible shielded control cables

5) Contactor: Schneider

6) Pneumatic part: Taiwan Airtac

7) Pressure sensor

3. Main components

Fully-automatic glass loading machine

Fully-automatic CNC glass cutting machine

Glass breaking machine

1pcs vertical level

YR-6133 glass breaking machine

1. Technical parameter:

Table top size: 6100×3300mm

Table top height: 900±30mm

Quantity of air fan: 2piece

(Independent switch control )

4. Technical parameter:

1) Max glass size: 2500*2000 Min glass size: 1000*1200( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 700mm

6) Loading weight: 500KG

7) Arm quantity in one side: 3 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 6KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. Software

Italy imported cutting and optimization software

Optimization software can match with ERP system.

Cutting position limitation

Calculate capacity automatically

More than two thousand cutting shape database. (Be easy to operate)

Match with AUTO CAD drawing software.

Optimization software can be used with cutting software directly.

Automatic calibration function makes ensure cutting accuracy.

Cutting route selection function makes ensure the best cutting speed.

Adjust cutting pressure automatically, fast, accurate and steady.

Adjust cutting pressure automatically when cutting different shape, to ensure cutting effect fast.

Automatic origin position can be search and setting.

Operation input: keyboard and mouse, Chinese and English interface.

Shape scan: different shape point to point scanning, and then transfer into CAD drawing.

Optimization software: combine and order the cutting size casually, output the best cutting solution and improve cutting efficiency. Manual revise after optimization which improve the cutting utilization rate.

Optimized pressure and speed: According to pattern, straight line, curve line, incurve and outcurve start point and end point;accelerative section and braking section, it can adjust the most suitable pressure and speed.

Shape database: database is available for different kinds of shape.

Shape optimization: change size, rotate, move and combine smoothly in the database.

Operation interface: Chinese and English interface, support many kinds of language.

Drill position:preposition of drill position.

Cutting head protection: mechanical protection function, avoid the possibility of crash.

Shape cutting: cut straight line and slant line and any shape automatically.

Transfer belt: motor drive belt directly and transfer the cutting glass into breaking machine.

Travel protection: mechanical and electrical double protection, to protect maximum travel protection.

Cutting pressure adjustment: Any cutting pressure adjustment can be adjusted by keyboard directly, no need manual operation.

8. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kinds of equipment are there in FRP production facilities?

- Grinding and mending toolsPainting equipment,There are winding forming and hand paste, and other forms of molding, I do not know the kind of question you ask

- Q: How do we polish the plexiglass after processing?

- Abrasive can use ordinary toothpaste, the effect is very good, the original young made plexiglass handicrafts, I tried.

- Q: Does anyone know where there are machines for making single, double layer glass by hand?

- The glass edge grinding machine has the advantages of simple structure and bilateral advanced, active edge by connecting group type supporting structure, glass transmission adopts the upper type transmission shaft, high precision glass two times the original positioning technology, using PLC control, man-machine interface system developed is simple and convenient, with a full set of stainless steel tank, high speed milling and good effect, stable performance, excellent quality, maintenance or equipment failure caused by the shutdown of the possibility is very small

- Q: How to choose insulating glass equipment / insulating glass production line?

- The difference between vertical insulating glass equipment and horizontal insulating glass equipment lies in the following points:A. appearance: vertical insulating glass production line, according to the model specifications are divided into 16001800200022002500, and so on, respectively, the total length of 13.8m, 17.8m, 20m, 22m, 24.3m. Width about 1.5-2m, height 2.78-3.5m or so. Horizontal glass cleaning machine also has 1600.1800.2000.2200.2500, etc., in which width of 1600 2.2M, 2.8m length, about 70 centimeters high.B. production efficiency: vertical insulating glass production line daily output of about 500 square meters, horizontal glass insulation equipment output of about 250 square meters. The above is based on a 8 hour work schedule.C. cost: 1600 vertical insulating glass production line, the whole set price is about 7w.Horizontal hollow glass equipment prices around 2.8w.

- Q: Problems in the mechanical processing of glass fiber reinforced plastics

- I think it is of little significance to use cutting fluid when machining frp. Because the heat of cutting is not enough, air cooling can satisfy. But there will be an environmental problem - dust flying, which is harmful to people when they are sucked in. Therefore, we used to buy a set of industrial vacuum cleaners, processing machine parts (work stations) partially closed, operators with industrial masks, quite troublesome. Have also tried to dial a special machine (milling machine) to make glass fiber reinforced plastic products. With coolant, the chip separation mechanism is specially made, which is similar to the filter of grinding machine.

- Q: Toughened glass production equipment and price

- 9 grinding head beveling machine more than 80 thousand; 19 thousand basic type profiled machines; drilling machine 18 thousand; washing machine price is unknown, specifications are type 2500, but also several class cleaning; normally want bilateral straight edge grinding machine, the price is unknown, probably need yiershiwan;

- Q: Method for making organic glass

- Hot pressingAfter the plexiglass sheet is heated, the mold is hot pressed in the mold. The handicraft made by the molding method has the characteristics of full body, smooth curve and strong stereoscopic feeling, and has the effect of relief. The hot pressing mould can be made of wood and oil sludge, and then cast lead and plaster material as the Yin and Yang mold. After the organic glass is heated, it can be pressed and formed.

- Q: How much does it cost to open a glass grinding machine shop?

- Then you add the original film, as well as store rent can be considered in all respects. If only on the straight side machine (straight side more commonly used more places), plus store (charge a three), the original film (enough on the line), a one hundred thousand should be able to open up.

- Q: Which equipment should be needed for a glass curtain wall processing plant?

- The number and type of equipment can be chosen according to your size and financial strength

- Q: I would like to open a toughened glass processing plant, that is, buy ordinary glass back, and then processed steel, I would like to ask those equipment, how much money do I need?

- As long as you learn how to manage your money, you can make a fortune without being a boss.

Send your message to us

YR-2520 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches