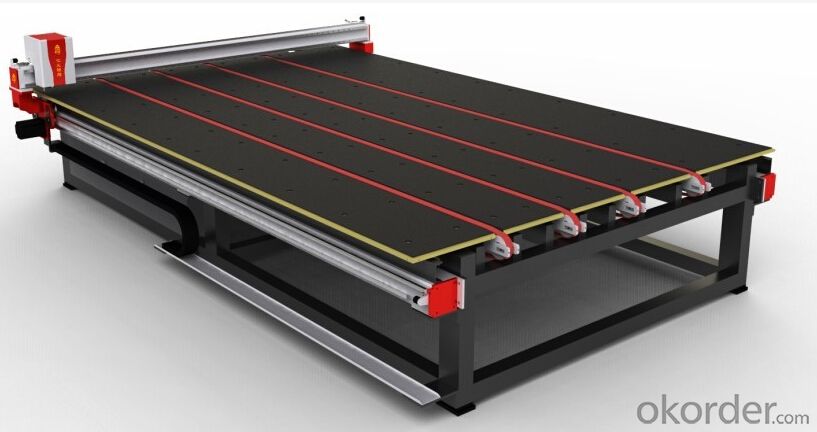

YR-4228 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Description of Automatic Glass Loading Machine

Glass Cutting Machine is Introduced in European advanced technology ,using the lasted technology and processing craft ,high-precision rack slide roll servo motor and starting components ,to achieve long-term precision and stability ,to achieve the effects of processing fast.Glass Cutting Machine adopt the lasted imported control system ,run faster ,higher security ,efficient and stable.Glass Cutting Machine has a lot of functions of photoelectric positioning ,accurate and easy to operate ,save more power.

1. The advanced mechanical structure ensures its stability and durability.

2. By importing Italy OPTIMA cutting and optimizing software and Italy TECNOS PLC, it features strengthened security, faster speed, more accuracy, easy operation, higher utilization rate, better stability, full functionality and more laborsaving.

3. Compatible to major ERP and office optimization system.

4. Easy to operate and labor saving.

2. Technical parameter

2.1 Basic parameter:

Max glass size: 4200*2800

Glass thickness: 3-19mm

Gross weight: 2.5T

2.2 Cutting parameter:

Linear parallelism: ≤±0.25mm/m

The diagonal accuracy: ≤±0.30mm/m

Cutting bridge speed: 0〜160m/min

Cutting bridge acceleration: ≥ 3.0m/s²

Cutting tool speed: ≥160m/min

Cutting tool acceleration: ≥ 6.0m/s²

Belt transmission speed: ≥ 40m/min

Cutting head accuracy: ≤±0.2mm

2.3 Power:

Power (installation): 380V/50HZ

Installed power: 8KW

Compressed air: 0.6Mpa

3. Main components

Fully-automatic glass loading machine

Fully-automatic CNC glass cutting machine

Glass breaking machine

1pcs vertical level

YR-6133 glass breaking machine

1. Technical parameter:

Table top size: 6100×3300mm

Table top height: 900±30mm

Quantity of air fan: 2piece

(Independent switch control )

4. Technical parameter:

Equipment performance

Equipment frame: guarantee accuracy and keep the shape.

Cutting tool apron: cutting head can rotate 360 degree.

Table top: imported waterproof HDF board

Felt: imported felt, smooth and anti-static

Cutting oil: pneumatic input oil automatically, cutting and oil synchronization

Transfer system: Synchronized belt transfer automatically.

Mechanical parts:

Table top: waterproof board

Rack: KHK

Transfer belt: Barbieri

Cutting wheel: Germany Bohle

Electrical parts:

Microsoft windows interface

Voltage: 380V/50HZ, equipped with transformer.

Motor: Japan YASKAWA sever motor

Approach switch: Switzerland ELCO

Control card: Italy imported TECNOS (match with Italy OPTIMA SOFTWARE)

Main electrical parts: Japan IDEC Relay, Schneider A. C. Contactor

Air proportional valve: Japan SMC

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. Software

Italy imported cutting and optimization software

Optimization software can match with ERP system.

Cutting position limitation

Calculate capacity automatically

More than two thousand cutting shape database. (Be easy to operate)

Match with AUTO CAD drawing software.

Optimization software can be used with cutting software directly.

Automatic calibration function makes ensure cutting accuracy.

Cutting route selection function makes ensure the best cutting speed.

Adjust cutting pressure automatically, fast, accurate and steady.

Adjust cutting pressure automatically when cutting different shape, to ensure cutting effect fast.

Automatic origin position can be search and setting.

Operation input: keyboard and mouse, Chinese and English interface.

Shape scan: different shape point to point scanning, and then transfer into CAD drawing.

Optimization software: combine and order the cutting size casually, output the best cutting solution and improve cutting efficiency. Manual revise after optimization which improve the cutting utilization rate.

Optimized pressure and speed: According to pattern, straight line, curve line, incurve and outcurve start point and end point;accelerative section and braking section, it can adjust the most suitable pressure and speed.

Shape database: database is available for different kinds of shape.

Shape optimization: change size, rotate, move and combine smoothly in the database.

Operation interface: Chinese and English interface, support many kinds of language.

Drill position:preposition of drill position.

Cutting head protection: mechanical protection function, avoid the possibility of crash.

Shape cutting: cut straight line and slant line and any shape automatically.

Transfer belt: motor drive belt directly and transfer the cutting glass into breaking machine.

Travel protection: mechanical and electrical double protection, to protect maximum travel protection.

Cutting pressure adjustment: Any cutting pressure adjustment can be adjusted by keyboard directly, no need manual operation.

8. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kinds of equipment are there in FRP production facilities?

- Cutting equipment -- cutting dry fiberglass fabric or prepreg to the desired shape.Forming heating equipment - generally divided into two parts: forming die and heating curing furnace.

- Q: What kind of equipment and adhesives are needed for plexiglass processing?

- Hot bending machine. Laser engraving machine. 502 glue。 Nothing else

- Q: How much do you charge for a set of insulating glass processing equipment?

- A set of insulating glass processing equipment can be divided into two horizontal and vertical, horizontal and divided into 1 glass washing and drying machine for hot press, mainly is the hollow glass manufacturing combined rubber strip type washing and drying machine; 2 butyl rubber coating machine

- Q: Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- The manufacturers of hollow glass equipment are concentrated in Ji'nan. Among them, the best is the Ji'nan Hao hollow glass equipment factory. Its equipment is of good quality, and the price is not reasonable. The service is also good.

- Q: How do you strengthen the glass and use the equipment?

- Ordinary annealed glass first cut into required size, and then heated to the softening point of 700 degrees, then rapid and uniform cooling of the glass (usually 5-6MM at 700 degrees high temperature heating about 240 seconds, 150 seconds of cooling. 8-10MM glass heating at 700 degrees high temperature for about 500 seconds, cooling about 300 seconds. In short, depending on the thickness of the glass, the choice of heating and cooling time is also different. After tempering, uniform compressive stress is formed on the glass surface, while tensile stress is formed inside the glass to improve the bending and impact strength of the glass. The strength of the glass is about four times higher than that of the ordinary annealed glass. Have good tempered glass, can no longer be any cutting, grinding or damaged, otherwise it will damage due to uniform compressive stress balance and smashed to pieces".

- Q: Status of glass machinery for glass machinery

- Construction and automotive glass and glass products, as substrates, play a more and more important role in the process of diversification. They bring opportunities and challenges for glass production and processing equipment. In 2014, flexible production process and multi-functional production equipment are the development trend of glass processing industry in the world. They require glass processing equipment to be highly repeatable and accurate. Automotive and construction glass has been committed to reducing glass thickness to meet market demand, which puts forward higher requirements for glass deep-processing technology. Many glass deep-processing enterprises have begun to improve the efficiency of the production line and integrate all aspects of glass deep-processing. This will be the future development trend of glass deep-processing industry.

- Q: I want to buy a glass grinder to process glass granules, but there is no market. Please point out the market for our predecessors

- Personally, can be made into handicrafts, with pieces of homegrown, can do a good job in Taobao to sell, pay attention to product packaging!

- Q: What milling cutters are used for machining plexiglass plates? Just ordinary drilling and milling machine, milling plane, not too precise

- Say ordinary white steel knife on the line, processing edge angle milling, so as not to collapse edge

- Q: How much is the equipment for toughened glass production?

- Tempering furnace factory:Luoyang RandyLuoyang BeiboLuoyang specialShundeShunde LinThe domestic several well-known, including Soos to the small furnace well, special bending steel is more famous, Randy and the north is the furnace in recent years by Mount Taishan and the North Star, growth.

- Q: I would like to open a toughened glass processing plant, that is, buy ordinary glass back, and then processed steel, I would like to ask those equipment, how much money do I need?

- (1) consider the knowledge needed by the market economy, and make less money. When you become the market needs a certain aspect of the expert, wealth began to close to you.(two) when you want to be a boss, you'd better go to work, study technology, learn management, learn how to invest and manage money, and how to be a boss. You can't be a boss. You will continue to learn from experts, improve your own quality, and find more profitable jobs.

Send your message to us

YR-4228 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches