Fully Automatic Industrial Washing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fully Automatic Industrial Washing Machine

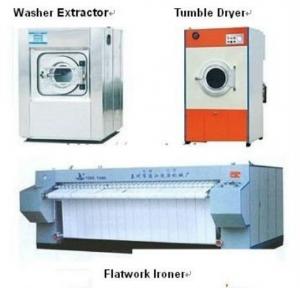

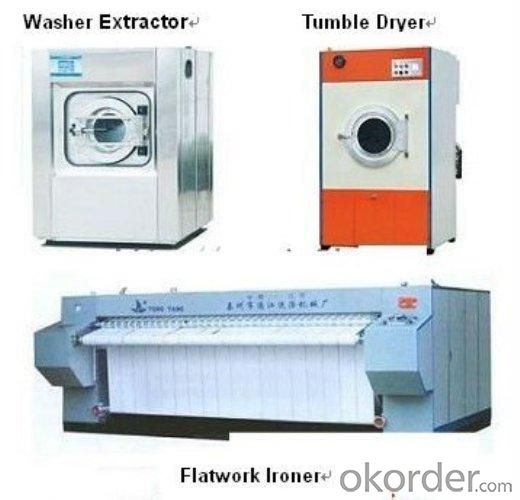

Automatic industrial washing machine

1.capacity:15KG-100H

2.certificates:CE and ISO9001

3.all stainless steel plate.

Fully Automatic Industrial Washing Machine

1.Loading large diameter stainless steel doors,equipped with safety locks facilitate loading grass cloth,beautiful and dueable,safe and reliable.

2.with the use of SUS304 high-quality stainless steel cage structure,advanced punching technology,effectively reduce the wear and tear on the grass cloth,durable.

3.composite vibration damping system,without a special foundation,applicable to any floor.

4.Germany imported the world famous“seaked reed” hydraulic pneumatic seals.Fluoroelastomers high quality materials,superi or manufacturing processed to ensure that durable sealedcasemouth.

5.Frequency using the German motor,low power consumpition,high efficiency,large torque and stable operation.

6.used non-linear frequency conversion speed control,stable operation,low noise.

Packaging & Delivery of Fully Automatic Industrial Washing Machine

Packaging Details: wooden case

Delivery Detail: 15days

Technical Parameter of Fully Automatic Industrial Washing Machine

| Type | XTQ-15H | XTQ-30H | XTQ-50H | XTQ-70H | XTQ-100H | |||

| Min | 10kg | 20kg | 35kg | 50kg | 70kg | |||

| Max | 15kg | 30kg | 50kg | 70kg | 100kg | |||

| Diameter | 650mm | 902 mm | 1015 mm | 1200 mm | 1200 mm | |||

| Diameter deepness | 450 mm | 500 mm | 610 mm | 626 mm | 785 mm | |||

| Volume | 149 mm | 320 mm | 528 mm | 708 mm | 887 mm | |||

| High | 1510 mm | 1760 mm | 1900 mm | 2300 mm | 2300 mm | |||

| Length | 1010 mm | 1410 mm | 1650 mm | 1850 mm | 1850 mm | |||

| Width | 1110 mm | 1430 mm | 1750 mm | 1800 mm | 2100 mm | |||

| Washing rotate speed | 50r/min | 36 r/min | 35 r/min | 33 r/min | 31 r/min | |||

| Uniformity speed | 90 r/min | 72 r/min | 75 r/min | 70 r/min | 65 r/min | |||

| Mid speed | 450 r/min | 420 r/min | 380 r/min | 350 r/min | 310 r/min | |||

| High speed | 890 r/min | 780 r/min | 760 r/min | 680 r/min | 680 r/min | |||

| Motor | 2.2Kw | 4.0 Kw | 5.5 Kw | 7.5 Kw | 7.5 Kw | |||

| Draining valve | Φ 70mm | Φ 140mm | Φ 140mm | Φ 140mm | Φ 140mm | |||

| Hot water pipe | 3/4″ | 3/2″ | 3/2″ | 3/2″ | 3/2″ | |||

| Cold | 3/4″ | 3/2″ | 3/2″ | 3/2″ | 3/2″ | |||

| Steam pipe | 3/4″ | 1″ | 1″ | 1″ | 1″ | |||

| Power supply | Standard:380+N-3PH-50Hz | |||||||

| Weight | 950kg | 1900kg | 2600kg | 2800kg | 3130kg | |||

- Q: What is the transformation of the textile industry?

- In China, Nike and Kentucky as a household name, if Taiwan from the technical side of the formation of transformation, the United States from the brand side to find the fulcrum. Through the brand, consumers can get a unique interest and experience, rational experience is based on the product, emotional experience is based on emotion. The same piece of clothing, paste the trademark of Nike, the value of immediately jump up, which is competitive!

- Q: What are the skills of the textile mill?

- The shuttle loom holds the weft with a small sheet-like shuttle with a clip and projects the weft insertion. The shuttle loom has the advantages of weft insertion stability, excellent fabric quality and low weft yarn. It is suitable for multi-color weft fabric, fine, thick fabric and wide fabric production.

- Q: What is luminous printing?

- Has a good luminous effect and excellent feel and fastness

- Q: What is Foam Stereo Printing?

- Foam Stereo printing refers to the addition of a blowing agent plastic resin to the printing slurry

- Q: How is China's textile and textile market prospects?

- Prospective Industry Research Institute released the "China Textile Machinery Manufacturing Industry demand and investment forecast analysis report" shows that China's textile machinery manufacturing industry in recent years to maintain rapid development momentum. As of the end of 2010, the industry total assets reached 77.613 billion yuan, an increase of 27.78%; industry sales revenue 815.65 billion yuan, an increase of 42.13%. Overall, after experiencing the decline in industry growth in 2008, the industry scale expansion rate significantly accelerated, the overall development trend is good.

- Q: What is used textile machinery import clearance process ?

- First determine the customs code (HS) of the equipment to confirm whether to allow imports, whether it relates to imported electromechanical

- Q: What is transfer printing?

- And then through the fabric and paper fuselage, the use of dye sublimation performance, after high temperature and pressure

- Q: What is the difference between the late Qing machine and the British steam textile machine?

- The meaning of the "omnipotent prime mover" steam engine has broken through the limitations of natural conditions on industrial development and promoted the development and progress of all industrial sectors.② Engels said: division of labor, especially the use of steam, the application of the machine, The mid-eighteenth century industry used to shake the old world's three great levers. (3) to promote the rapid development of heavy industry and transportation.

- Q: What is the textile handmade textile?

- The original loom was originally directly separated by the fingers of the warp, and later changed to the stick opening and playing latitude. This stick gradually evolved in the shape, thickness and function have a difference, that is, with the comprehensive pole (or heald rod), sub-stick and weaving knife division of labor. The heap is also developed from one to several or ten roots to suit the needs of the weave pattern

- Q: What is the difference between textile ink and digital printing ink?

- Non-woven digital printing direct injection paint ink, textile white paint ink primer dedicated, after rubbing fastness, washing fastness, light fastness, color and other strict testing, to the textile industry technical requirements.

1. Manufacturer Overview

| Location | Taizhou, China |

| Year Established | 2003 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 28000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Fully Automatic Industrial Washing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords