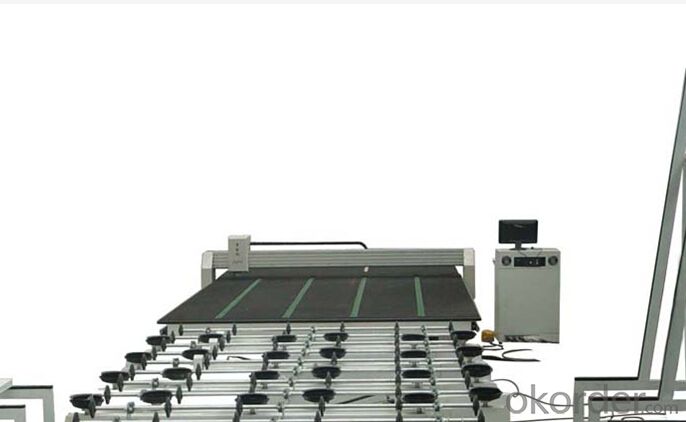

YR-6133 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

By digesting advanced technology abroad, combined with our R & D and innovation, the working performance of it can reach same level of best products of same type, with compact structure and high strength of machinery, and adopting bevel gear to transmit and stable travel in lifting & descending and X,Y axis, without vibration and having reliable performance. These machine adopts PLC and human interface control,with high working efficiency and low labor cost. Its features and functions are as below:

1. Controlled by PLC, imported from Japan.

2. Equip Germany vacuum system

3. Move with Linear Guide.

4. work automatically with hadraulic system, easy to operate the machine by computer.

5. The machine can know the opsition of the glass sheet automatically, and transfer the sheet to the cutting position by the roller.

2. Technical Parameter:

Max glass size: 6100*3300

Work table height: 900mm±30mm

Gross weight: 3.8T

Glass thickness:3-19mm

3. Cutting Parameter:

Linear parallelism: ≤±0.25mm/m

The diagonal accuracy: ≤±0.30mm/m

Cutting bridge speed: 0〜160m/min

Cutting bridge acceleration: ≥ 3.0m/s²

Cutting tool speed: ≥160m/min

Cutting tool acceleration: ≥ 6.0m/s²

Belt transmission speed: ≥ 40m/min

Cutting head accuracy: ≤±0.2mm

Power (installation): 380V/50HZ

Installed power: 8KW

Compressed air: 0.6Mpa

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kinds of equipment are there in FRP production facilities?

- Paving equipment - use under special circumstances.Proportional coating equipment - if there are a number of components, heat it up in the heating molding equipment after gluing.

- Q: How is the inorganic fiberglass ventilating pipe produced? Is it produced by hand or by mechanical production? What equipment do you need?

- The main raw material is glass cloth and resin, first attached to the mold on a layer of glass cloth, then coated resin, layer by layer, after reaching the design thickness and shape and curing is finished.

- Q: Can the engraving process 2*2mm grooves on plexiglass plates?

- Engraving machines with a cutter instead of a laser engraved on a polymethyl methacrylate is no problem. The transmittance of polymethyl methacrylate is very high. In addition, I would like to say that this material has a notch, sensitive and easy to crack, I do not know what to do.

- Q: Just opened a glass processing plant, want to buy glass machinery, there is better

- Buy glass machinery, can go to Shunde shengteng machinery, glass machinery in the country: Shunde!

- Q: Who knows how the glass is processed into fiberglass? How much is the approximate price of the equipment?

- The method of replacing platinum crucible is a widely used process at present. Its raw material is glass ball. "Tank" is currently the most advanced technology, the raw material powder is a mixture of "pyrophyllite based".

- Q: What equipment do you need to produce glasses? Is the process complicated? Are there many raw materials?

- Glass production process mainly includes: (1) raw material pretreatment. The massive raw materials are crushed to damp the raw materials, and the iron containing materials are treated with iron to ensure the quality of the glass. Preparation of batch. Melting system. The glass batch is heated in a bath or crucible furnace at high temperature to form a liquid glass which is uniform, free of bubbles and conforms to the molding requirements. Shaping. The processing of liquid glass into desired shapes, such as flat plates, various vessels, etc.. Heat treatment. Through annealing, quenching and other processes, to eliminate or produce glass internal stress, phase separation or crystallization, and change the state of glass structure.

- Q: Is it complicated to produce double glass? We invest about how much money?

- The raw material for making glass is to enter the glass tube without melting it. There are technical staff sealing, if not good, so do out of the cup is not good, scrap rate will be very high.

- Q: Toughened glass production equipment and price

- Then you have to pay back money, inventory, rent, utilities, wages, etc.. If these are entirely new investments, about 250-300.

- Q: What milling cutters are used for machining plexiglass plates? Just ordinary drilling and milling machine, milling plane, not too precise

- Engraving machine is best to use, the speed is fast, and the accuracy is good

- Q: What are the plexiglass processing equipment?

- There are casting equipment, as well as cracking monomer recovery equipment, I do not know what you use to do. And how big is your equipment?

Send your message to us

YR-6133 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches