YR-600 automatic round & shaped glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

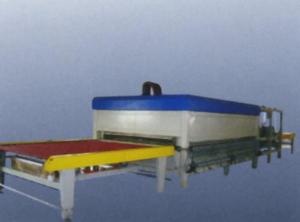

Full-automatic Glass Cutting Line

1. Description of Automatic Glass Loading Machine

Glass Cutting Machine is Introduced in European advanced technology ,using the lasted technology and processing craft ,high-precision rack slide roll servo motor and starting components ,to achieve long-term precision and stability ,to achieve the effects of processing fast.Glass Cutting Machine adopt the lasted imported control system ,run faster ,higher security ,efficient and stable.Glass Cutting Machine has a lot of functions of photoelectric positioning ,accurate and easy to operate ,save more power.

1. The advanced mechanical structure ensures its stability and durability.

2. By importing Italy OPTIMA cutting and optimizing software and Italy TECNOS PLC, it features strengthened security, faster speed, more accuracy, easy operation, higher utilization rate, better stability, full functionality and more laborsaving.

3. Compatible to major ERP and office optimization system.

4. Easy to operate and labor saving.

2. Technical parameter:

I. Product Model: YR-600 automatic round & shaped glass cutting machine

II. The Max. Glass Cutting Thickness: 1~15mm

The Max. Dia. of Cutting Round: 550mm

Cutting Accuracy: ≤±0.10mm

Cutting Speed: 0~80 pieces/min( adjustable)

No. of Operators: 1 person( 1 person can operate 2~3 machines)

Scope of Application: the round and shaped glass for Make-up mirror, crafts, pot cover, lamps and automobile rear-view mirror.

3. Main components

Fully-automatic glass loading machine

Fully-automatic CNC glass cutting machine

Glass breaking machine

1pcs vertical level

YR-6133 glass breaking machine

1. Technical parameter:

Table top size: 6100×3300mm

Table top height: 900±30mm

Quantity of air fan: 2piece

(Independent switch control )

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode (automation and manual)

11) Operation screen: Color LCD touch screen interface

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

8. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- I am professional and technical personnel of doors and windows, I think you want to build a factory doors and windows, doors and windows products will be posted to the direction of processing and higher secondary development, the most popular is Aluminum Alloy insulation doors and windows, doors and windows is another high-end aluminum composite wood or solid wood doors and windows.

- Q: Can plexiglass be machined with a punch?

- Organic glass can not punch processing, processing would be a glass like to break

- Q: What equipments are used in glass production?

- There are a lot of the original film production, drawing machine, annealing furnace, cutting machine (cutting, slitting), conveyor, stacking machine, machine hand,..... A lot of equipment, glass processing upstairs two ranked almost, mainly depends on what kind of glass you produce

- Q: How much money do you need to invest in making glass hot bending? What equipment should I buy?

- It depends on what kind of hot bending glass you want to make, depending on the size of the glass

- Q: How to choose insulating glass equipment / insulating glass production line?

- Hollow glass equipment is divided into two types of vertical and horizontal: vertical automatic hollow glass plate production line, butyl rubber coating machine, horizontal glass cleaning dryer and butyl rubber coating machine.

- Q: Mobile phone glass engraving machine capable of processing large size?

- Single head can process 400*400*100mm, double head can process 350*500*100*100mm, I know so much, I hope I can help you.

- Q: How to polish plexiglass and acrylic machine after machining?

- Organic glass melts; then the rough grinding wheel. We also tried to use toothpaste dipped in water to polish, the effect is slightly better, but still can not meet the requirements, but also manual, inefficient

- Q: Problems in the mechanical processing of glass fiber reinforced plastics

- Glass fiber reinforced plastic (FRP) is a kind of glass fiber and epoxy resin composite material. It has high chemical stability. It can not react in water soluble emulsion. Your situation is hard to say. It is recommended that the sample be taken to a special institution for chemical analysis to see the change in acidity and alkalinity. There may be a solution.

- Q: How much is the equipment for toughened glass production?

- Type 2436 (2440 * 3660) flat steel furnace is about 900 thousand or so, the prices of different manufacturers are different. Matching pretreatment equipment: 9, grinding machine linear machine about 40 thousand; 9 grinding head beveling machine more than 80 thousand;

- Q: Which equipment should be needed for a glass curtain wall processing plant?

- It depends on how much money you invest, how much equipment you have, and how many products you have, but the more you invest

Send your message to us

YR-600 automatic round & shaped glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches