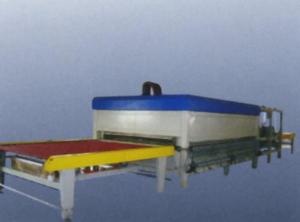

YR-12533 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-12533 Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

By digesting advanced technology abroad, combined with our R & D and innovation, the working performance of it can reach same level of best products of same type, with compact structure and high strength of machinery, and adopting bevel gear to transmit and stable travel in lifting & descending and X,Y axis, without vibration and having reliable performance. These machine adopts PLC and human interface control,with high working efficiency and low labor cost. Its features and functions are as below:

1. Controlled by PLC, imported from Japan.

2. Equip Germany vacuum system

3. Move with Linear Guide.

4. work automatically with hadraulic system, easy to operate the machine by computer.

5. The machine can know the opsition of the glass sheet automatically, and transfer the sheet to the cutting position by the roller.

2. Mechanical components:

1) turning wheel chain: high precision reinforced type

2) transfer idler wheel : PU

3) vacuum suction cup: double absorption structure

4) transfer/turning motor: Taiwan CPG motor

5) vacuum pump: PUXU( Sino-Germany)

3. Electric elements.

1) PLC controller: Delta

2) Transducer: Delta

3) Proximity switch: Swiss ELCO

4) Control cable: High-flexible shielded control cables

5) Contactor: Schneider

6) Pneumatic part: Taiwan Airtac

7) Pressure sensor: SMC

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What brand machines do you need to produce double glass? How much is the equipment? How much is the material? Can a large area do? Do you use artificial water for producing ordinary drinking glasses?

- The production of double cup need automatic tube cutting machine, automatic necking machine, sealing machine, annealing oven, equipment investment of about 100 thousand, the material according to their production budget of 200 thousand, work area of 500 to 1000 level, you can find a master seal,

- Q: What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- Aluminum Alloy doors and windows equipment sawing aluminum section glass bead saw corner cutting saw automatic (semi-automatic) heavy angle automatic cutting machine (CNC / digital) numerical control double head cutting saw heavy (efficient) single head cutting saw (NC) aluminum profile cutting machine of 45 aluminum doors and windows of arbitrary angle precision CNC double head cutting saw group. NC four head angle machine (vertical and horizontal) multi angle machine end milling head profile milling machine (Dan Tou) row curtain wall Tenoing machine milling machine milling machine (five knife) stamping press bending machine hardware punch hollow glass equipment vertical insulating glass production line of glass washing machine automatic production line automatic pressure plate rolling production line of vertical insulating glass production line glass washing machine horizontal hot press laminating horizontal cold roller press hollow glass auxiliary equipment of glass washing machine horizontal hot press and horizontal Sheet cold roll press curtain wall processing equipment, planer groove, drilling equipment, aluminum curtain wall composite board, planer slot machine

- Q: The factory is doing glass deep-processing, and now want to purchase glass deep-processing equipment, glass grinding machine is now required, I would like to ask you have manufacturers recommend it?

- Clamping glass, digital display table shows 00120, indicating the glass after clamping 12mm, 00050 represents 5mm glass, later used for some time, may need to re adjust the digital display.

- Q: What kind of machinery and equipment do we need for the glass processing plant?

- Look what line you need to go, there are architectural engineering and Art Deco, and others, Art Deco, mainly carved machines, mosaics, sandblasting and painting.

- Q: Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- Glass cleaning machine butyl rubber coating machine - two-component adhesive machine. The price is different, high and low.

- Q: Do you use UV flatbed printers for glass processing?

- UV flatbed printer according to the printing efficiency and configuration performance of different, the price between 1-60w all, equipment manufacturers and card research and development center in Hangzhou. Finally, it is important to note that when you buy equipment, you need to pay attention to refitting equipment and original equipment.

- Q: I'd like to open an art glass processing factory. What equipment do I need?

- Find a glass art processing factory to work for a period of time, process and equipment do not know, the enemy can ever victorious, I also want to do glass processing technology, but no money, can only think of.

- Q: Is it complicated to produce double glass? We invest about how much money?

- The equipment for making glass is not very complicated, so it can be done with several machines. Cutting tube, sealing, oven, holding furnace. That's all. But now it's harder for sealing workers. A total investment of about one hundred thousand can be done.

- Q: Do you need professional tools for machining plexiglass? What about acrylic boards?

- Heating method: organic glass processing to a certain shape, the organic glass is heated directly by hand, rapid forming system, wo. Some laws require prior to the composition of the answers, agile, coherent. The arts and crafts made by this method have the advantages of bold lines and simple image.The above methods can be used alternately, according to the artistic requirements of the design, determine the best method.

- Q: What are the main equipments for making insulating glass? How much would a whole set of funds be?

- Aluminum insulated glass equipment also needs a butyl coating machine, two component punch or not, a vertical production line of about 10 million

Send your message to us

YR-12533 Full Automatic glass loading machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches