YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-4228 full automatic CNC glass cutting machine

Product General Description

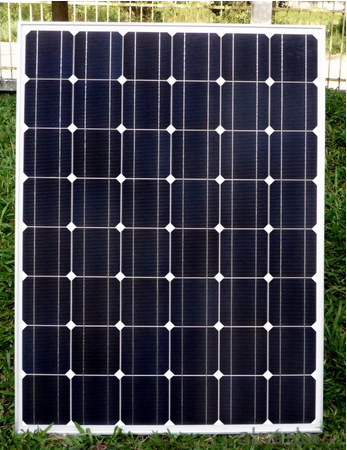

A photovoltaic (in short PV) module is a packaged, connected assembly of typically 6×10 solar cells. Solar Photovoltaic panels constitute the solar array of a photovoltaic system that generates and supplies solar electricityin commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 365 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, a solar inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

Physical characteristic

Equipment frame: guarantee accuracy and keep the shape.

Cutting tool apron: cutting head can rotate 360 degree.

Table top: HDF board

Felt: imported felt, smooth and anti-static

Cutting oil: pneumatic input oil automatically, cutting and oil synchronization

Transfer system: Synchronized belt transfer automatically.

Mechanical parts

Table top: HDF board

Rack: KHK

Transfer belt: Barbieri

Cutting wheel: Germany Bohle

Electrical parts

Microsoft windows interface

Voltage: 380V/50HZ, equipped with transformer.

Motor: Japan YASKAWA sever motor

Approach switch: Switzerland ELCO

Control card: Italy imported TECNOS (match with Italy OPTIMA SOFTWARE)

Main electrical parts: Japan IDEC Relay, Schneider A. C. Contactor

Air proportional valve: Japan SMC

Calculate capacity automatically

- Q: How do we polish the plexiglass after processing?

- Edelweiss DX it depends on your final transparency, I used to use when PC resin is first with 200 to 400 change to rough polishing, fine polishing. Transparency is ok.

- Q: Can organic glass be processed two times?

- . Electrical and mechanical equipment panel, windows and shell, is widely used in protective masks, insulating fittings, hot forming parts, automobile, machinery, chassis, plastic mold, metal lighting, clocks, gifts, plastic electronics and other industries.

- Q: What kind of equipment does the toughened glass production line include?

- Tempered glass production line: upper panel of control system, heating furnace body, wind spring, lower piece, typhoon machine, air compressor

- Q: Who knows how the glass is processed into fiberglass? How much is the approximate price of the equipment?

- Glass fiber production has "clay crucible method", "replacing platinum crucible method" and "pool kiln" three process methods. "Clay crucible method" is the most primitive process,

- Q: What are the types of automotive glass production lines?

- In the domestic and foreign automotive glass production line with France Japan Asahi, Saint Gobain, British Pilkington, Saint Gobain and Asahi which are the world's top 500 enterprises, Asahi Glass automotive glass alone to enter the world top 500, Pilkington is the earliest invention of float glass, now the most famous glass manufacturers have bought their technology, many car manufacturers designated by the original glass pilkington.

- Q: What kind of machinery and equipment do we need for the glass processing plant?

- Engineering has toughened, hollow, laminated! But none of them left the cutting and edging machines

- Q: I'd like to open an art glass processing factory. What equipment do I need?

- Find a glass art processing factory to work for a period of time, process and equipment do not know, the enemy can ever victorious, I also want to do glass processing technology, but no money, can only think of.

- Q: Which equipment does the glass mirror need?

- Some equipment needed for processing glass mirror:Cutting tools, glass knife (blade), square, tape, cut = = if the conditions can be automatic cutting machine on a (about 150 thousand on the I)

- Q: How do you make plexiglass?

- With a file or emery cloth for coarse grinding, chamfering and rounding with fine gauze and then polished, finally with ordinary toothpaste with a soft cloth polishing line. When grinding, pay attention to protect, good to hurt the front.

- Q: Can glass fiber reinforced plastics be machined with high precision?

- Matters needing attention(1) because the mechanical properties of glass fiber products are brittle and brittle, it is difficult to clamp. The clamping force causes the workpiece to deform or block the workpiece, and the excessive force will cause the workpiece to fly off.(2) because of the glass fiber heat is relatively poor, linear expansion into relatively large, the workpiece is easy to deform, the size is more difficult to control.(3) the best data can be obtained only through process experiments.

Send your message to us

YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches