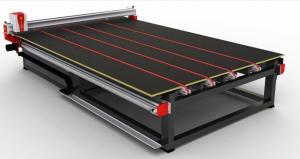

YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-4228 Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

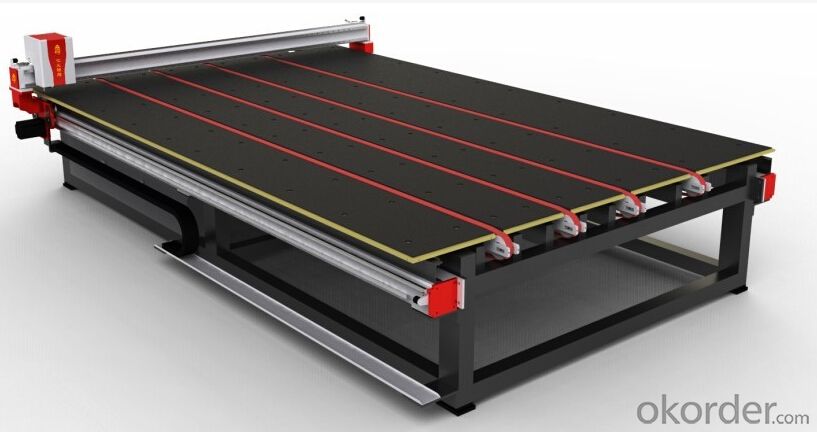

The automatic loading & unloading system use variable frequency motor as drive source, to ensure smooth running and jitter-free. Transfer table uses chrome-plated shaft fitted with polyurethane wheel and synchronous belt. All main frame of equipment use Alufer welded and fitted with bolt. Electric control system of equipment use Schneider brand modules of electric; Program control uses imported SIMEINS programmable controller, fitted with touch panel.

Equipment System: main frame/ running system/ transfer system/vacuum adsorption system/mechanical turning system/high and low pressure control system/program control system.

Glass loading and unloading systems with suction cups.

2. Mechanical components:

1) turning wheel chain: high precision reinforced type

2) transfer idler wheel : PU

3) vacuum suction cup: double absorption structure

4) transfer/turning motor: Taiwan CPG motor

5) vacuum pump: PUXU( Sino-Germany)

3. Electric elements.

1) PLC controller: Delta

2) Transducer: Delta

3) Proximity switch: Swiss ELCO

4) Control cable: High-flexible shielded control cables

5) Contactor: Schneider

6) Pneumatic part: Taiwan Airtac

7) Pressure sensor: SMC

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: Toughened glass machine more money?

- How large is the construction of this machine?! How many kinds of toughened glass machine do you need?! How many squares of glass can we produce in a day?

- Q: The factory is doing glass deep-processing, and now want to purchase glass deep-processing equipment, glass grinding machine is now required, I would like to ask you have manufacturers recommend it?

- Before starting, connect the pump, fill up the water, turn on the machine and observe whether the belt is turning. Under the correct circumstances, is the water pump adequate? If it is not correct, replace the two lines in the power supply.

- Q: How much is the mini toughened glass factory and what other equipment?

- 6.1 technical risk: production technology of tempered glass is higher, in addition to have a certain theoretical basis, but also have practical experience, if improper operation may cause explosion, bending loss; therefore, in order to avoid unnecessary losses must carry out technical and safety training for employees, working closely with the manufacturer cooperative unit and the furnace, and invited to have many years of relevant experience in the master manipulator.6.2: marketing risk in marketing, due to fierce competition between industry and industry, the phenomenon of vicious competition will appear to beat each other, resulting in reduced profit margins, but each toughened glass factory, the foreign manufacturers have relatively low transportation cost advantage, and no sales in the middle, sent directly to the customer, can shorten the delivery cycle, enhance market competitiveness.6.3 procurement risk: the price of raw materials and raw materials directly affect the quality of corporate profits and market share, measures are taken in March in late November to the next year according to the law of the market is the price of raw glass trough, during this period, Randy proposed to hold time machine reserves of raw glass to ensure the maximization of profits, the price after a period of time.

- Q: How much do you charge for a set of insulating glass processing equipment?

- A set of insulating glass processing equipment can be divided into two horizontal and vertical, horizontal and divided into 1 glass washing and drying machine for hot press, mainly is the hollow glass manufacturing combined rubber strip type washing and drying machine; 2 butyl rubber coating machine

- Q: What equipments are used in glass production?

- There are a lot of the original film production, drawing machine, annealing furnace, cutting machine (cutting, slitting), conveyor, stacking machine, machine hand,..... A lot of equipment, glass processing upstairs two ranked almost, mainly depends on what kind of glass you produce

- Q: Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- Glass cleaning machine butyl rubber coating machine - two-component adhesive machine. The price is different, high and low.

- Q: Can individuals do quartz glass processing? What kind of equipment do you have? How much does it cost? Is there a high demand for technical content?

- A light machine is a glass lathe. Buy smaller ones, but with thicker walls. Blow the size you want and then cut the ends off. Oxyhydrogen burning. After softening, the mold is blown with the mouth, and the graphite mold is also needed. Look at the size you require. You need a better lamp worker. If the quantity needed to compare the big words. Machines can be made to order. On both sides of PW or cloth stepper motor, mobile head, first feed. After the material has been uniformly burned. The length is consistent. The wall thickness can be even.

- Q: Method for making organic glass

- Paste methodCut the plexiglass into a definite shape and paste it on the surface.

- Q: How much does it cost to open a glass grinding machine shop?

- Cleaning machine twenty-two thousand or so. I have this machine, so I can tell you the approximate price. Depending on what kind of glass you make, what machinery do you need?.

- Q: Waste glass processing equipment

- Auxiliary equipment: fuel storage and supply system; fan and air supply system; combustion system

Send your message to us

YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches