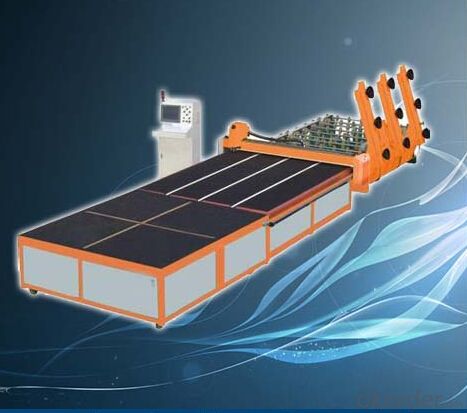

2015 Full and Semi automatic glass cutting machine for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

We are a high-tech enterprise specialized in the research, manufacture and sale of Aluminum-PVC door & window production equipment,glass processing equipment. Our products sell very well in China and are exported to many foreign countries and regions.

We have many experienced technical engineers and experts who have been worked in this industry for many years.

2. Technical parameter:

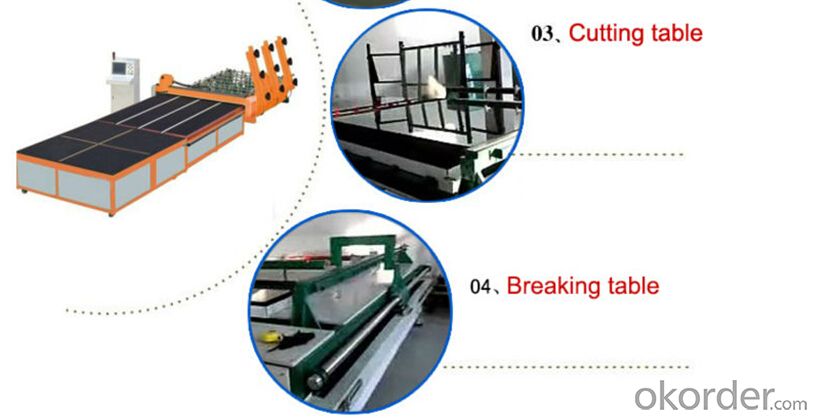

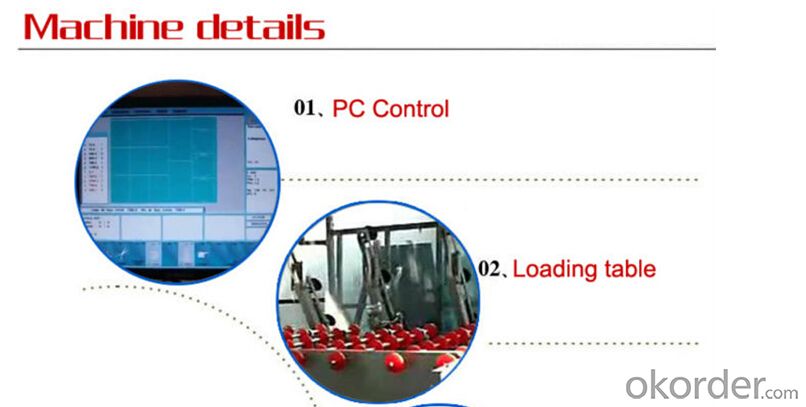

1).Equipment performance

Cutting Holder: Using Japan SMC Proportion solenoid valves, According to the glass thickness automatic adjustment pressure, The cutting holder Rotate 360°.

2).Positioning System

Mechanical photoelectric joint positioning

3). Conveying Device

AIR and Belt conveyor

3. Features of our Machine Line

CNC Auto Glass Cutting Machine Production Line adopt the most advanced Italy software.

Use imported high precision rack, slider and servo-motor, can be operated longer and faster.

CNC process control system, photoelectric positioning, convenient and accurate, airbag cutting, smooth precision.

Applicable to construction curtain walls, auto windshield, crafts, furniture, hollow, solar glass, etc, or set cutting for linear or special-shaped glass.

4. Main Introduction: Automatic glass loading machine

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment. On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the covered amount of your payment. Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment. Product Details Company Profile Transactions History.

Report Suspicious Activity Company Information Packaging & Shipping Our Services FAQ Quick Details Condition: New Machine Type: Insulating Glass Production Line Production Capacity: 1200piece/day

Place of Origin: Shandong, China (Mainland)Brand Name: PARKER Model Number: IGV22

Voltage: 220-380v 50hzPower(W): 23.7kwDimension(L*W*H): 21000x2100x3300mm

Weight: 4800kgsCertification: CE Warranty: 1 years

5. Our Service for our customers

Packing and shipping

Packaging Detail: in plastic film and container

Delivery Detail: 30-60 days once receiving from the first payment

Payment terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: The thickness of the epoxy glass cloth laminates by machining method for machining the thin board?

- Can be made, and now there are various specifications of the sheet for your choice, if it is the whole board is not good processing. It's too loud. Or the size is too large, and of course, depends on how thick it is, how thin it is.

- Q: Just opened a glass processing plant, want to buy glass machinery, there is better

- Luoyang, of courseMany glass processing equipment is produced in Luoyang, especially the glass toughened equipment. The Randy glass machine in Luoyang is very famous in the glass deep-processing industry

- Q: Toughened glass machine more money?

- How large is the construction of this machine?! How many kinds of toughened glass machine do you need?! How many squares of glass can we produce in a day?

- Q: Glass mechanical grinding, grinding wheel mesh 180, belonging to the grinding edge? What is the appearance quality?

- 180 the glass of the grinding wheel of the target wheel must be opaque and visible. A washing forming section, visible grinding machine, wheel configuration: No. 1, wheel 180*, No. 2, wheel 300*, wheel 3, 400--500, 2 sets of polishing wheels (resin wheel)After tempering glass is generally not recommended for grinding 1. first in the process of grinding wheel 1, adjust properly it will break the glass and the conveyor belt are likely to scrap (we will destroy the 2 synchronous belt 2.) after tempering grinding will damage much toughened glass compressive stress layer after grinding blew the chance increased

- Q: Does anyone know where there are machines for making single, double layer glass by hand?

- Lattice glass machinery specializing in the production of glass double edge grinding machine. Company bilateral machine manufacturing technology innovation constantly, advanced structure, high quality, stable and reliable performance.

- Q: How much do you charge for a set of insulating glass processing equipment?

- Mainly processing aluminum strip type of insulating glass; 3 cleaning dryer and hot melt adhesive machine, mainly processing hot-melt adhesive hollow glass.

- Q: How much money do you need to invest in making glass hot bending? What equipment should I buy?

- It depends on what kind of hot bending glass you want to make, depending on the size of the glass

- Q: How much will it cost to machine ordinary glass into toughened glass? Where can I buy it?

- Different from the raw material, the ordinary glass can be burned by tempering furnace and cooled into toughened glass. Machine made Guangzhou more, of course, more expensive abroad, and good quality. Generally open a steel plant, no 4 million, do not open.

- Q: How to polish plexiglass and acrylic machine after machining?

- The combustion of hydrogen and oxygen for combustion, flame, zero pollution, high production efficiency, the flame is not pure blue smoke and dust, especially suitable for polishing organic glass, acrylic and other materials, is one of the necessary equipment for making crystal characters, so it is also known as organic glass flame polishing machine

- Q: Can individuals do quartz glass processing? What kind of equipment do you have? How much does it cost? Is there a high demand for technical content?

- A light machine is a glass lathe. Buy smaller ones, but with thicker walls. Blow the size you want and then cut the ends off. Oxyhydrogen burning. After softening, the mold is blown with the mouth, and the graphite mold is also needed. Look at the size you require. You need a better lamp worker. If the quantity needed to compare the big words. Machines can be made to order. On both sides of PW or cloth stepper motor, mobile head, first feed. After the material has been uniformly burned. The length is consistent. The wall thickness can be even.

Send your message to us

2015 Full and Semi automatic glass cutting machine for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches