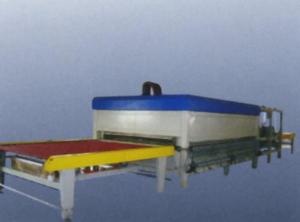

YR-2520 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-2520 Full-automatic glass cutting machine

product description

Equipment frame: guarantee accuracy and keep the shape.

Cutting tool apron: cutting head can rotate 360 degree.

Table top: imported waterproof HDF board

Felt: imported felt, smooth and anti-static

Cutting oil: pneumatic input oil automatically, cutting and oil synchronization

Transfer system: Synchronized belt transfer automatically.

Electrical parts:

Microsoft windows interface

Voltage: 380V/50HZ, equipped with transformer.

Motor: Japan YASKAWA sever motor

Approach switch: Switzerland ELCO

Control card: Italy imported TECNOS (match with Italy OPTIMA SOFTWARE)

Main electrical parts: Japan IDEC Relay, Schneider A. C. Contactor

Air proportional valve: Japan SMC

Feature

Italy imported cutting and optimization software

Optimization software can match with ERP system.

Cutting position limitation

Calculate capacity automatically

More than two thousand cutting shape database. (Be easy to operate)

Match with AUTO CAD drawing software.

Optimization software can be used with cutting software directly.

Automatic calibration function makes ensure cutting accuracy.

Cutting route selection function makes ensure the best cutting speed.

Adjust cutting pressure automatically, fast, accurate and steady.

Adjust cutting pressure automatically when cutting different shape, to ensure cutting effect fast.

Automatic origin position can be search and setting.

Operation input: keyboard and mouse, Chinese and English interface.

Shape scan: different shape point to point scanning, and then transfer into CAD drawing.

Physical characteristic

Optimization software: combine and order the cutting size casually, output the best cutting solution and improve cutting efficiency. Manual revise after optimization which improve the cutting utilization rate.

Optimized pressure and speed: According to pattern, straight line, curve line, incurve and outcurve start point and end point;accelerative section and braking section, it can adjust the most suitable pressure and speed.

Shape database: database is available for different kinds of shape.

Shape optimization: change size, rotate, move and combine smoothly in the database.

Operation interface: Chinese and English interface, support many kinds of language.

Drill position:preposition of drill position.

- Q: What kinds of equipment are there in FRP production facilities?

- Grinding and mending toolsPainting equipment,There are winding forming and hand paste, and other forms of molding, I do not know the kind of question you ask

- Q: Can organic glass be processed two times?

- Two organic glass molding and precision cutting, according to design drawings, plates, cutting, carving, drilling, milling, polishing, bending, adhesive, hot pressing, printing, sandblasting, coating and other processing, maintained at a certain angle and shape, to meet customer requirements.

- Q: The thickness of the epoxy glass cloth laminates by machining method for machining the thin board?

- The 2MM board will be on the five or six floor, huh?! However, this is what happened in those years, in the playing cards do not buy the age of stripping this to do their own playing cards, I do not know whether the situation is now glued to improve it, you can try. Reproduction of a variety of thickness of this kind of plate, and more is that you choose the right one, not on the line.

- Q: Glass mechanical grinding, grinding wheel mesh 180, belonging to the grinding edge? What is the appearance quality?

- Because it is curtain wall engineering, four sides of the glass have rubber sealed choice, such grinding edge is possible, but the grinding wheel is too thick, the rate of finished products is affected180 the glass of the grinding wheel of the target wheel must be opaque and visible. A washing forming section, visible grinding machine, wheel configuration: No. 1, wheel 180*, No. 2, wheel 300*, wheel 3, 400--500, 2 sets of polishing wheels (resin wheel)

- Q: Who knows how the glass is processed into fiberglass? How much is the approximate price of the equipment?

- Glass fiber production has "clay crucible method", "replacing platinum crucible method" and "pool kiln" three process methods. "Clay crucible method" is the most primitive process,

- Q: Where there is a machine for processing glass, that is, you can empty an empty wine bottle into a crystal, or a bead

- The material of the utility model is processed by the blank with little amount of grinding, and the melting and refining standards are very high, and the color, purity and transmission are transparent...It's not ordinary glass. It can be counterfeited.If it could have been done hundreds of years ago.

- Q: How much money do you need to invest in making glass hot bending? What equipment should I buy?

- If big size, then large equipment to do their own simple 1830mm*2400mm*800mm to about fifteen thousand

- Q: I want to buy a glass grinder to process glass granules, but there is no market. Please point out the market for our predecessors

- Personally, can be made into handicrafts, with pieces of homegrown, can do a good job in Taobao to sell, pay attention to product packaging!

- Q: Do you need professional tools for machining plexiglass? What about acrylic boards?

- 1, paste method: organic glass cut into a certain shape, paste in the flat surface.2 、 hot pressing method: after the plexiglass sheet is heated, the mold is hot pressed in the mold. The handicraft made by the molding method has the characteristics of full body, smooth curve and strong stereoscopic feeling, and has the effect of relief. The hot pressing mould can be made of wood and oil sludge, and then cast lead and plaster material as the Yin and Yang mold. After the organic glass is heated, it can be pressed and formed.3, mosaic method: the different colors of plexiglass block cut into the required geometry, in the bottom plate mosaic splicing. This method requires tight stitching, edges and corners, and a strong, yet seamless effect.4, vertical grinding method: rod shaped organic glass or thick plate plexiglass after bonding, grinding directly on the grinding wheel, polishing molding. The arts and crafts made by this method are similar to some sculptures. They are made up of colorful surface shapes to form a unique artistic image.

- Q: Which equipment should be needed for a glass curtain wall processing plant?

- Crane, two-component glue injection machine, double sawing, sawing platform, angle machine, drilling and milling machine, air compressor and fixture fixture.

Send your message to us

YR-2520 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches