2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

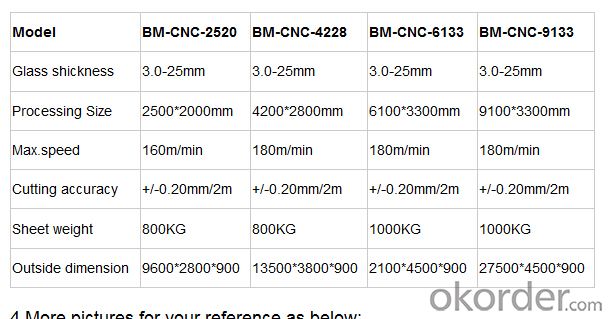

2. Technical parameter:

3. Features of our Machine Line

1). After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the CNC cutting table. Under laser sensory element guidance, use laser-reader to get the position of the glass-sheet. Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2). After cutting, glass will move to the Breaking Glass Table . Start break bars and to break the glass. At this point, the whole process work is completed.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

INSTALLATION CHARGE

USD70/day for one worker for installation and training. Buyer supply hotel,food,ticket. Our technical worker need about 3-10 days for installation till all machines is good. When our worker finished all installation, buyer have to pay for installation charger to our worker according to $70 per day. Then our worker will teach your worker how to operate all machines correctly.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: How do we polish the plexiglass after processing?

- Abrasive can use ordinary toothpaste, the effect is very good, the original young made plexiglass handicrafts, I tried.

- Q: What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- I am professional and technical personnel of doors and windows, I think you want to build a factory doors and windows, doors and windows products will be posted to the direction of processing and higher secondary development, the most popular is Aluminum Alloy insulation doors and windows, doors and windows is another high-end aluminum composite wood or solid wood doors and windows.

- Q: What kind of equipment and adhesives are needed for plexiglass processing?

- Cutting saw polishing machine polishing machine pistol drill trichloromethane disposable syringe Pervez silicone tape ruler compasses basically are the best in a curve saw

- Q: What are the types of automotive glass production lines?

- In the domestic and foreign automotive glass production line with France Japan Asahi, Saint Gobain, British Pilkington, Saint Gobain and Asahi which are the world's top 500 enterprises, Asahi Glass automotive glass alone to enter the world top 500, Pilkington is the earliest invention of float glass, now the most famous glass manufacturers have bought their technology, many car manufacturers designated by the original glass pilkington.

- Q: Can plexiglass be machined with a punch?

- Organic glass can not punch processing, processing would be a glass like to break

- Q: Can plexiglass be machined with CNC milling machines?

- Tolerable。What exactly do you do, such as engraving, embossing, or simply cutting plexiglass?.

- Q: Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- How much do you have to see the process, as well as post production; if small, with horizontal equipment, cheap; mainly glass washing machine, coating machine, Ding Ji two-component glue machine; if the production amount is very large, it is necessary to use vertical insulating glass production line and Ding Ji coating machine, double a glue machine.

- Q: Toughened glass production equipment and price

- Then you have to pay back money, inventory, rent, utilities, wages, etc.. If these are entirely new investments, about 250-300.

- Q: Installation and debugging of insulating glass processing equipment

- (1) site conditions shall include 380V AC power supply, industrial source water supply and drainage ditch. Most of the insulating glass equipment and door and window equipment are 380V, mainly in order to maintain the stability of equipment work. Clean unsolicited water supplies, as well as unblocked drainage, are the guarantee for the good work of the cleaning machine.(2) correctly place the feeding section, the frame, the cleaning section, the frame, the drying section, the frame, the discharging section, the frame, the control cabinet and the ventilation case. If not placed in order, will reduce work efficiency, two will not pass the product quality.

- Q: Can glass fiber reinforced plastics be machined with high precision?

- Matters needing attention(1) because the mechanical properties of glass fiber products are brittle and brittle, it is difficult to clamp. The clamping force causes the workpiece to deform or block the workpiece, and the excessive force will cause the workpiece to fly off.(2) because of the glass fiber heat is relatively poor, linear expansion into relatively large, the workpiece is easy to deform, the size is more difficult to control.(3) the best data can be obtained only through process experiments.

Send your message to us

2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches