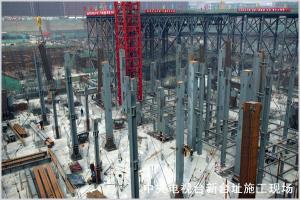

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TMCPhigh-strengthsteel(non-tempered):E500.Q500E.S500M.

1.SA516Gr70. SA516Gr65.S355series.P355series.Q345Rseries.AH32-36.DH32-36.EH32-36.Intensitylevel isQ345Eclass.P460.S460 (-20 ℃impact)seriesQ460Dclasses.

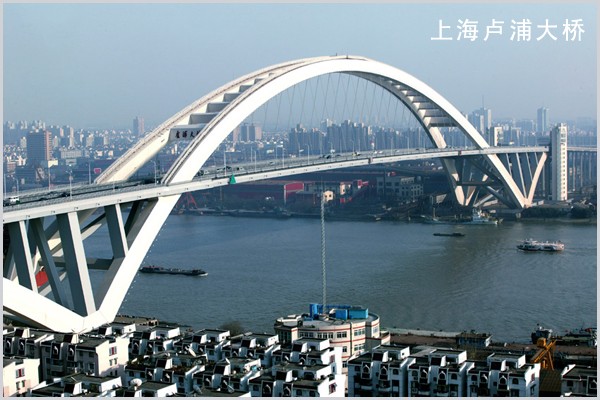

2containers.Ship plate steeland other specialsteels,at the sameintensity levelbase priceplus500 yuan/ ton.

1: AsolutionHICSteel(HIC-A)toBsolutionHICsteel(HIC)basisplus300 yuan/ton.

2: R-HICHICsteeltosteelAsolution(HIC)basisplus500 yuan/ ton.

3: TypeII HICsteel100 yuan/ton, IIItypeHICsteelplus400 yuan/ ton.

4:For theHICsteelQ345R SA516Gr70 SA516Gr65correspondingclassQ345RQ245RQ245R SA516Gr60correspondingclass..

6, nuclearHRsteelcontainersincludeda quality plan,the completion ofthe report,all the requirements forsimulationafter weldingand so on.

- Q: Are lead contained in galvanized steel plates and plain steel plates?

- Steel plate is made of molten steel, cooled and compressed into flat steel.

- Q: What is the difference between a satin and mirror finish steel sheet?

- The main difference between a satin and mirror finish steel sheet lies in their appearance. A satin finish has a smooth, brushed texture with a muted sheen, while a mirror finish has a highly reflective, glossy surface that resembles a mirror. The satin finish is achieved through a process of sanding or brushing the steel, creating fine lines or grain, whereas a mirror finish requires additional polishing and buffing to achieve its reflective quality.

- Q: How is the normalized steel plate produced?

- Normalizing is the process of heating a steel member to 30-50 degrees above the critical temperature and cooling it in stationary air after proper heat preservation. This process is called normalizing.

- Q: Can steel sheets be used for decorative column wraps?

- Yes, steel sheets can be used for decorative column wraps.

- Q: Are steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting if they are not adequately protected or exposed to moisture and oxygen.

- Q: What is AO steel plate?

- It is better to meet the anatomical angle and bone surface in steel plate and Futie professional medical professional operation, to fracture the bones to firm, stable and maximum support.

- Q: Do steel sheets require any special storage or handling?

- Yes, steel sheets require special storage and handling to ensure their integrity and avoid any damage. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion. Additionally, they should be stacked in a way that prevents distortion or bending. When handling steel sheets, it is important to use proper lifting equipment and techniques to prevent accidents and maintain the quality of the sheets.

- Q: What are the different types of steel sheet finishes?

- There are several different types of steel sheet finishes, including mill finish, brushed finish, mirror finish, galvanized finish, and painted finish.

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel sheets offer durability, strength, and a sleek appearance, making them suitable for various architectural applications including cladding or facade systems. They can be customized in terms of color, finish, and shape, allowing for versatile design possibilities. Additionally, steel sheets provide weather and fire resistance, making them a reliable choice for exterior applications.

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

Send your message to us

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords