WPC SOS Certification Board Outdoor Decking

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

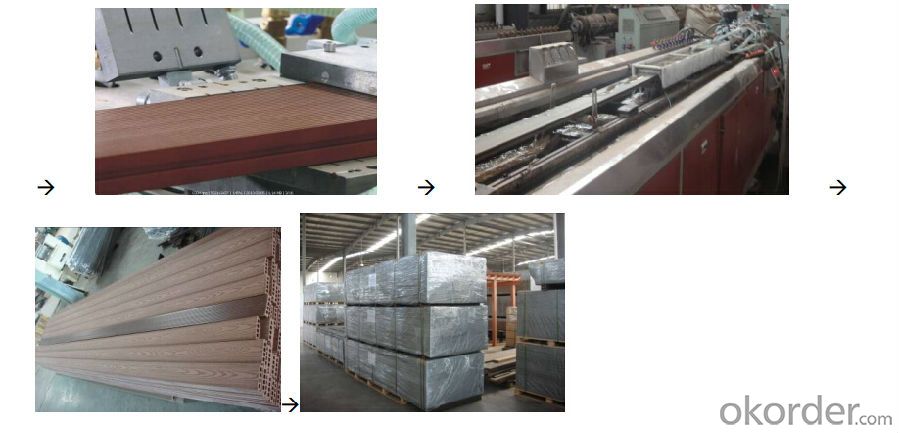

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

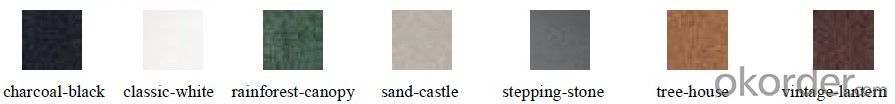

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

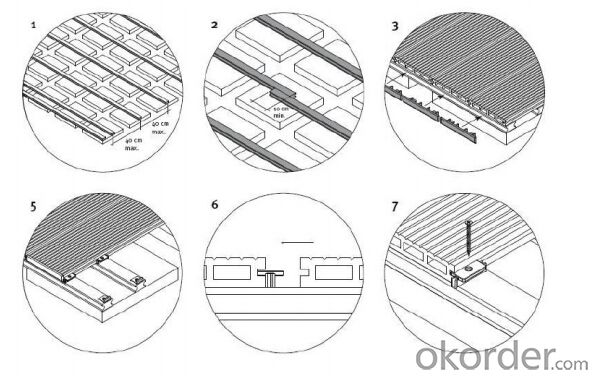

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: Accidentally sprinkle nail polish on the floor of the tiles, how to do?

- With a brush or wire ball can be wiped with water, and finally wipe with a mop on the clean.

- Q: when turn the control to floor very little comes out,

- ifthe air is good on defrost and vent but not on floor then you have a vacuum line off inside your dash...that is how it switches over....pull the unit and check the cables and lines....it is also possible that your switch is stripped and moving too far or not far enough.....when you hit the floor position, it reads floor but isnt all the way there.,....just a few adjustments should do it...

- Q: I am putting floating laminate floors in my kitchen. Do I run them under the cabinet toe kicks or up to the and then run a bead of caulk?

- Up to the kick , leaving a 1/4 inch gap for the expansion and contraction..Most often done is to cover that gap w/ a shoe molding, nailed to the toe kick. This has to be done all around the perimeter (gap) so a shoe molding is put all around the perimeter too. 3/4 shoe is the recommendation from every laminate maker I ve put in. Caulking , you won t be able to get a nice looking bead since the gap is a 1/4 inch.Plus you cant get the board cuts all perfect anyway, to make it look good. You can paint or stain molding to match baseboards. GL

- Q: My family is a new district, this year is the first year of heating. The use of collective heating in the home of the long pedicle short Li's mattress to warm, the hall is the tiles, the temperature can have 18 degrees to 20 degrees, but the room is the wood floor, the temperature is only about 13 degrees, the temperature difference is too large , DX can help you out where the problem is ah? More

- The problem of heating is high and the height is lowered

- Q: I have just primed a wood floor and want to stencil it. After the priming do I paint the entire floor the background color then stencil?. What do I use for the final coat(s) to protect the floor and the stenciling?

- Whenever you paint a floor, it is recommended to use an epoxy-based paint - it will adhere better and suffer much less wear and tear over time because it is more durable. Although, truth be known, I have used acrylic paints with no problems. Presuming you're using a simple stencil pattern to be applied on a solid-coloured background, your next step is to paint the background colour. Two coats should do the trick. Let it dry thoroughly before stencilling over it. Stencilling should be done with a stencil brush - a round brush with a perfectly flat tip. The paint should be thinly applied in a dabbing motion - do not brush it on. The reason for this, aside from the finished look, is that when you brush paint on it is more likely to get under your stencil and make a mess. If you're using more than one colour, you might want to cover the areas on the stencil for all but one colour with masking tape, and let each colour dry before moving on to the next. When you're all done, you could apply a clear coat. The oil or alkyd-based clear coats have a tendency to yellow slightly over time and take quite a while to dry. The water based clear coats won't hold over oil-based paint or emulsion. Check with your local paint supplier to find out which finishing product is best based on the paints you have used. Alternately, depending on the style you are going for, if you have used a durable enough paint, you might want to skip the clear coat so that over time you will have a nice aged and worn-in look to the floor. Good luck.

- Q: Fillinger strengthen the composite floor which series of good?

- This composite floor is basically countable, the price is more moderate, the other recommended Huili brand composite floor.

- Q: i don't understand what to do if a formula has the word floor in it. What do I put there?

- The term floor usually means the same thing as minimum. If it makes sense in the context of what you are doing.

- Q: if this helps my laminate floor is not cheap

- Follow manufacturers advice, but I hear Orange Glo is a good mild cleaner for laminates.

- Q: Dogs had a peeing problem in the middle of my floor and over time the sides of the flooring have come up. Is it possible to sand it down then stain it? P.S. Dont want to replace the entire floor.

- Pergo flooring is not natural wood. It is very hard and therefore will be hard to stain. Older pergo flooring was installed by gluing the boards together and the newer type are installed by 'clicking' the boards together. Hope this info helps.

- Q: im trying to clean the floors in my living room, but i was told not to use water or anything like that because it could damage the wood. we have laminate pergo floors in the house, what is something safe to clean it with that will still work well?

- The thing to avoid is allowing water to stand on the floor for a long period of time. Water will soak into the seams of the boards and cause them to swell and delaminate. Damp mopping is fine, just don't soak the floor. Good cleaners to use are ammonia or vinegar in hot water. Home improvement stores sell special laminate cleaners but they are made of ammonia and water. No matter what two hundred people tell you, do not use Murphy's oil soap or any kind of oil, wax, or soap. They may look good at first but leave residue that will eventually make the floor very dull and filmy. Many people have trouble eliminating streaks when cleaning Pergo. The only way to get rid of all the streaks is to dry the floor after cleaning. Using very hot water also will aid in streak control.

Send your message to us

WPC SOS Certification Board Outdoor Decking

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords