Woven Geotextile Fabric Prices - Staple Fiber Needle Punched Geotextile (2-6m)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Staple Fiber Needle Punched Geotextile:

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament

geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the

process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the

traditional engineering materials and construction methods, construction is more secure, and contribute to

environmental protection, can be more economic, effective and lasting to solve basic problems in engineering

construction.

Main Features of Staple Fiber Needle Punched Geotextile:

1, tensile and tearing resistance, bursting resistance, resistance to puncture, such as high mechanical strength, is equally grams weighs more than doubling of staple fiber geotextile, especially bursting resistance, strength reached more than 2200 Newton, in the stone slope protection, can effectively prevent irregular stones on the impact of the cloth;

2, good extension performance, stress dispersion and transmission is fast, make the uniformly distributed load;

3, the friction coefficient is big, not easy to slip when construction;

4, good chemical resistance;

5, corrosion resistance;

6, ageing resistance, embedded laid, the service life of more than 50 years;

7, heat resistant, cold resistant performance is good, can withstand 200 ~ 30 ℃ temperature difference and the quality is not affected;

Specifications of Staple Fiber Needle Punched Geotextile:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

| Packaging | packed in roll or as the customer's requirements |

| Delivery | 10 days after get the deposit |

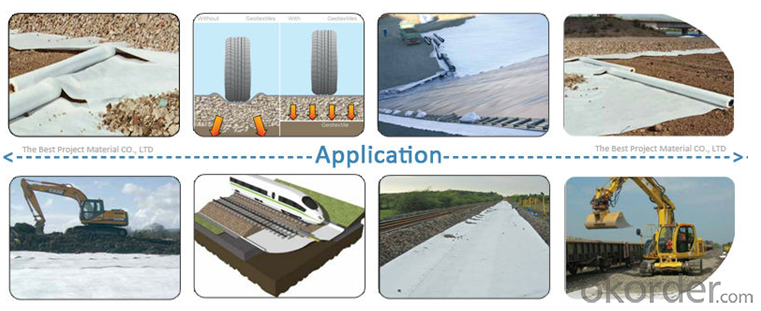

Applications of Staple Fiber Needle Punched Geotextile:

1.Seperation of different material:applied between subgrade and groundwork of the paved(un-paved) roador airport road.Applied between the subgrade and ballast of the railway,applied in the landfill ground and gravelsubgrad,applied between the geomembrane and sandy drainage layer,applied between the subgrade and ground work to undertake the additional load.Applied between the earth of groundwork and foundation soil,applied under footpath,parking lot,stadium,applied between the new and old asphalt.

2.Reinforcement of the soft foundation:applied on the soft foundation of the unpaved road,the airport path,railroad,the landfill,the stadium,etc prevent the geomembrane to be punctured by the gavel.

3.Filtration:applied at the bottom of the lanfill that penetrate,to protect the geonet and geocomposite and prevent the soil to enter inside.

4.Drainage:applied under the geomembrane,the stadium,the ballast of the railway.

IMages of Staple Fiber Needle Punched Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- We use the soil is a geotech cloth waterproof board

- Q: Geotextile cost how much money a flat

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: Hope expert expert to give the answer

- 1, side ditch, drains, blind ditch, cut ditch are road drainage facilities. 2, the drainage system is divided into the form of surface water and row of groundwater. Row of surface water: side ditch, drains, cut ditch; row of groundwater: blind ditch. 3, according to the road plane position is divided into: side ditch in the road side; drains can also be in the road side in the central zone; trench in the cutting section above; blind ditch in the roadbed width range. 4, according to the direction of the road is divided into: the direction of the ditch along the way; drains can also be the direction of the road can also cross the direction; cut the ditch along the way; blind ditch can be any direction. 5, according to the drainage function and cross-sectional size is divided into: drainage section of the largest; blind ditch second; side ditch, cut the smallest ditch. 6, according to the construction materials can be divided into: ditch can be pulp, dry piling, ramming, etc .; drains for the pulp or dry puzzle; blind ditch for the dry, pulp, gravel, concrete, ) And other combinations; cut ditch for the dry, pulp, ramming and so on. 7, according to the embankment type is divided into: fill, fill in the dug with a ditch, ditch, blind ditch; digging side, half filled half digging section ditch, drains, blind ditch, The ditch appears only in the digging section.

- Q: What is the geotextile of the asphalt pavement?

- You should be talking about concrete pavement and asphalt pavement with what geotextile bar, asphalt pavement dedicated filament singeing geotextile, is a way to enhance the road and roadbed of the new fine geotextile. It has high tensile strength, high elastic modulus, excellent resistance to high and low temperature performance, excellent acid resistance and aging resistance. In short, filament singeite geotextiles are widely used in asphalt pavement , Cement concrete pavement and roadbed enhancement

- Q: Application of composite geotextile

- Water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. They are commonly employed as a separation layer between subgrade soils and the ballast, helping to prevent the mixing of materials and providing stability. Geotextiles also aid in drainage, filtration, and erosion control, enhancing the overall performance and lifespan of railway tracks.

- Q: Are geotextiles resistant to UV degradation?

- Yes, geotextiles are generally resistant to UV degradation. They are designed to withstand exposure to sunlight and other environmental factors, ensuring their durability and longevity in various applications.

- Q: Can geotextiles be used in sports field construction?

- Yes, geotextiles can be used in sports field construction. Geotextiles are commonly used as a part of the base and drainage system in sports field construction to prevent soil erosion, improve stability, and enhance the overall performance and durability of the field.

- Q: Can geotextiles be used in geotextile wrapped columns?

- Yes, geotextiles can be used in geotextile wrapped columns. Geotextiles are commonly used as a wrapping material for columns in geotechnical engineering applications. They provide reinforcement, prevent soil erosion, and enhance the stability of the column structure.

- Q: Can geotextiles be used in green roof construction?

- Yes, geotextiles can be used in green roof construction. Geotextiles are commonly used as a separation layer between the growing medium and the drainage layer in green roofs. They help prevent the migration of fine particles into the drainage layer and maintain proper water flow within the system. Additionally, geotextiles can enhance root penetration and overall stability of the green roof.

Send your message to us

Woven Geotextile Fabric Prices - Staple Fiber Needle Punched Geotextile (2-6m)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords