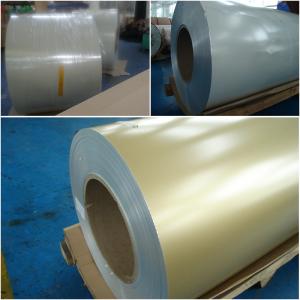

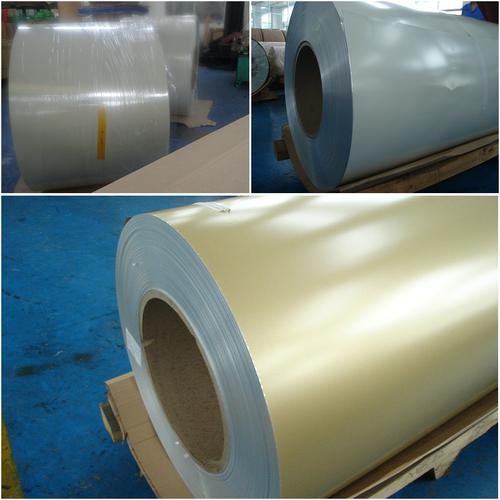

Wood Grain Aluminum Coil Stock - PE Prepainted Aluminum Alloy Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: What are the potential applications of coil-painted aluminum coils?

- Coil-painted aluminum coils have a wide range of potential applications across various industries. The coil-painting process involves applying a layer of paint onto aluminum coils before they are shaped and formed into different products. This process enhances the durability and aesthetic appeal of the aluminum, making it suitable for a variety of uses. One potential application of coil-painted aluminum coils is in the construction industry. The coated aluminum can be used for roofing, siding, and façade systems. The paint adds an extra layer of protection against corrosion and weathering, ensuring the longevity of the building materials. Additionally, the wide range of colors and finishes available in coil-painted aluminum allows for customization and design flexibility in architectural projects. Another application is in the automotive industry. Coil-painted aluminum can be used for manufacturing car body panels, trim, and other exterior components. The paint provides a smooth and consistent finish, enhancing the aesthetics of the vehicle. Additionally, the lightweight nature of aluminum makes it an ideal material for improving fuel efficiency, and the coil-painting process further enhances its resistance to scratches and fading caused by UV rays. Coil-painted aluminum coils also find applications in the manufacturing of appliances, such as refrigerators, ovens, and air conditioning units. The painted surface not only enhances the appearance of the appliances but also protects them from corrosion and wear and tear. The coil-painted aluminum can be easily formed into different shapes and sizes, allowing for efficient production of various appliance components. Furthermore, coil-painted aluminum is commonly used in the signage industry. The vibrant colors and durable finish achieved through the coil-painting process make it an excellent choice for outdoor and indoor signage. The aluminum coils can be cut, shaped, and formed into different sign types, including channel letters, lightboxes, and dimensional signs. In summary, the potential applications of coil-painted aluminum coils are extensive. From construction and automotive industries to appliances and signage, the enhanced durability, aesthetic appeal, and customization options of coil-painted aluminum make it a versatile material for various manufacturing purposes.

- Q: What are the compositions of aluminum coil coating?

- The common compositions are crylic resin, solid inorganic filler, different pigments, flatting agent and so on.

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- - its easy to put a spool of Al wire in a mig welder, but that isn't the issue. as mentioned previously, the Al wire is very soft and may present problems feeding through the long feed tube. hence the design of the spool gun ... tube length = none ... no

- Q: What are the different coil winding options for aluminum coils?

- There are several coil winding options for aluminum coils, including random winding, layer winding, and helical winding. Random winding involves winding the aluminum wire in a haphazard manner, while layer winding involves winding the wire in a neat, concentric manner. Helical winding, on the other hand, involves winding the wire in a spiral or helix pattern. Each winding option has its own advantages and is chosen based on specific requirements and applications.

- Q: What is the cost involved in the production of an aluminum coil?

- <p>The cost to produce an aluminum coil varies significantly based on several factors. These include the cost of raw materials, energy costs for melting and rolling, labor, and overhead expenses. Additionally, the price of aluminum on the commodities market directly impacts the cost. As of recent market trends, the cost can range from a few hundred to several thousand dollars per ton, depending on the specific alloy and thickness of the coil. It's essential to consider the current market prices for aluminum and the efficiency of the production process when calculating the cost to produce an aluminum coil.</p>

- Q: What are the different types of surface treatments for aluminum coils?

- There are several different types of surface treatments available for aluminum coils. These treatments are designed to enhance the appearance, durability, and corrosion resistance of the aluminum. 1. Anodizing: This is a popular surface treatment method that involves creating a protective oxide layer on the surface of the aluminum. Anodizing can be done in various colors, which adds aesthetic value to the coils. It also improves resistance to corrosion and wear. 2. Painting: Aluminum coils can be coated with high-quality paints to provide a decorative and protective finish. The paint can be applied in a wide range of colors and finishes, such as matte, gloss, or metallic. Painting not only enhances the appearance but also provides additional protection against corrosion and UV rays. 3. Powder Coating: This is a process in which a dry powder is applied electrostatically to the aluminum coils and then cured under heat. Powder coating provides a durable and attractive finish that is resistant to chipping, scratching, and fading. It is available in a wide variety of colors and textures. 4. Chemical Conversion Coating: This treatment involves applying a chemical solution to the aluminum surface, which creates a thin layer of protective coating. The conversion coating improves the corrosion resistance of the aluminum and also provides a good base for subsequent paint or powder coating. 5. Brushing: Brushing is a mechanical surface treatment that involves using abrasive brushes to create a textured finish on the aluminum coils. This process can be used to achieve a brushed or satin-like appearance, which adds a unique aesthetic appeal to the coils. 6. Embossing: Embossing involves creating raised patterns or textures on the surface of the aluminum coils. This treatment not only enhances the visual appeal but also improves the strength and stiffness of the aluminum. Embossed coils are often used in architectural and decorative applications. Overall, the choice of surface treatment for aluminum coils depends on the specific requirements and desired appearance. Each treatment offers its own unique benefits in terms of durability, corrosion resistance, and aesthetic appeal.

- Q: Is it possible to utilize aluminum coils for the purpose of storage?

- <p>Yes, aluminum coils can be used for storage, particularly in industrial settings. They are often used for storing materials such as paper, plastic films, and other coilable products. Aluminum coils are lightweight, corrosion-resistant, and can be easily transported and handled. They are also recyclable and environmentally friendly. However, their suitability for storage depends on the specific application and the type of material being stored. It's important to ensure that the coils are stored in a dry, clean environment to prevent damage and maintain their integrity.</p>

- Q: What are the common safety precautions when working with aluminum coils?

- Some common safety precautions when working with aluminum coils include wearing personal protective equipment such as gloves, safety glasses, and appropriate clothing to protect against cuts and burns. It is important to handle the coils with care to prevent injury, as they can be heavy and have sharp edges. Additionally, workers should be cautious when operating machinery or tools around the coils to avoid accidents. Proper ventilation should be ensured in the work area to prevent the buildup of fumes or dust. Lastly, workers should be trained on proper lifting techniques and be aware of the potential hazards associated with working with aluminum coils.

- Q: Classification of aluminium rolls for aluminium rolls

- On behalf of 6061, mainly contains two elements of magnesium and silicon, so it focuses on the advantages of the 4000 series and the 5000 series, and the 6061 is a cold treatment aluminum forging product, which is suitable for applications with high corrosion resistance and oxidation resistance.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

Send your message to us

Wood Grain Aluminum Coil Stock - PE Prepainted Aluminum Alloy Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords