Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Grain Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Wooden Grain Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Grain Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

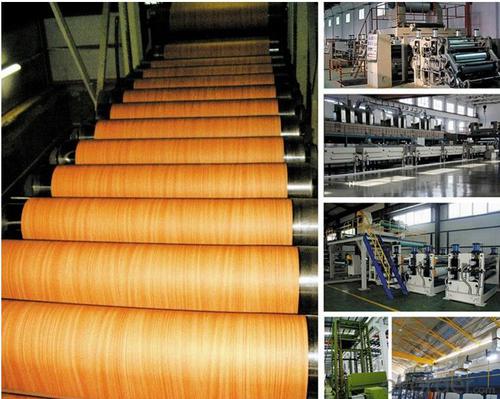

5. Image of Wooden Grain Coating Aluminum Coil with High Quality

6. Package and shipping of Wooden Grain Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils protected against dust and dirt during storage?

- Various measures are implemented to safeguard aluminum coils against dust and dirt during storage, guaranteeing their quality and preventing potential damage. One commonly employed technique involves securely wrapping the coils with protective coverings, such as plastic or polyethylene sheets, effectively creating a barrier against dust and dirt particles. These coverings are usually sealed tightly to prevent any entry of contaminants. Besides wrapping, other precautions are taken to minimize the risk of dust and dirt buildup. Storage areas are diligently maintained and cleared of debris to decrease the chances of contaminants settling on the coils. Regular cleaning and maintenance of the storage space are necessary to maintain a dust-free environment. Furthermore, storage facilities utilize proper ventilation and air filtration systems to regulate airborne particles and uphold a clean atmosphere. These systems aid in reducing the amount of dust and dirt that can accumulate on the coils. Proper handling of the aluminum coils during transportation and storage is also crucial to prevent unnecessary exposure to dust and dirt. Employing appropriate handling equipment and techniques, such as using clean gloves and avoiding dragging the coils on the ground, helps avoid the accumulation of contaminants. By implementing these protective measures, aluminum coils can be stored safely and securely, ensuring the preservation of their quality and averting any potential issues arising from dust and dirt buildup.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are certain restrictions on the coil thickness of aluminum coils. The thickness of aluminum coils may vary depending on the specific application and manufacturing process. However, it is generally limited by practical constraints such as the equipment capabilities, handling and transportation considerations, and the desired properties of the final product.

- Q: What is an aluminum coil?

- Aluminum coils, which are wound into a coil shape, consist of a continuous strip or sheet of aluminum. They possess properties that make them highly sought-after in various industries, including their lightweight nature, resistance to corrosion, and malleability. The production of these coils involves a method known as continuous casting and rolling, wherein molten aluminum is poured into a caster and subsequently rolled by large metal rollers to achieve the desired thickness and shape. The utilization of aluminum coils is widespread in the fabrication of automotive components, construction materials, electrical apparatus, and packaging products. Depending on the specific application demands, these coils can undergo further processing to take on different forms, such as sheets, plates, or foils.

- Q: What are the different packaging options available for aluminum coils?

- There are several packaging options available for aluminum coils, depending on the specific needs and requirements of the customer. Some common packaging options include: 1. Wooden crates: Aluminum coils can be packaged in sturdy wooden crates to provide maximum protection during transportation and storage. The crates are typically made of high-quality wood and are designed to withstand rough handling and prevent damage to the coils. 2. Cardboard boxes: For smaller aluminum coils, cardboard boxes can be used as a packaging option. These boxes are lightweight, cost-effective, and offer adequate protection against minor impacts and environmental factors. 3. Steel or aluminum skids: Another option for packaging aluminum coils is to place them on steel or aluminum skids. Skids provide a stable base for the coils and allow for easy handling using forklifts or pallet jacks. They are commonly used for larger coils or when multiple coils need to be transported together. 4. Stretch wrap: Stretch wrap is a popular choice for packaging aluminum coils as it provides excellent protection against dust, moisture, and scratches. The coils are tightly wrapped in a layer of plastic film, ensuring they stay secure during transportation. 5. Custom packaging: In some cases, customers may require customized packaging solutions to meet specific requirements. This can include using protective covers, foam padding, or additional reinforcements to ensure the safe handling and delivery of the aluminum coils. It is important to note that the choice of packaging option depends on various factors such as coil size, weight, transportation method, and the intended use of the coils. Working closely with a reputable packaging provider can help determine the most suitable packaging option for aluminum coils.

- Q: What are the different types of alloys used for aluminum coils?

- Aluminum coils are commonly made using several different types of alloys. The most frequently used alloy for aluminum coils is 3003, which is known for its excellent corrosion resistance and moderate strength. It finds its application in roofing and siding where high strength is not a requirement. 5052 is another alloy that is commonly used for aluminum coils. This alloy possesses good weldability and formability, making it suitable for a wide range of uses. In the automotive industry, it is often employed for body panels and fuel tanks. 6061 is a popular choice for aluminum coils due to its outstanding strength. It is frequently used in structural applications, such as aircraft parts in the aerospace industry and structural components in the construction industry. Additionally, other alloys like 1100, 5005, and 8011 are also used for aluminum coils. Each of these alloys has distinct properties and characteristics that make them suitable for different applications. For instance, 1100 is known for its high electrical conductivity and is commonly used in electrical applications. On the other hand, 8011 is frequently utilized for packaging and food containers due to its excellent corrosion resistance. In conclusion, the various alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys possess different properties and characteristics, making them suitable for a wide range of applications across industries like automotive, aerospace, construction, and packaging.

- Q: This question asks for a comparison between aluminum coil and other types of wire, highlighting their differences.

- <p>Aluminum coil is a type of wire made from aluminum, known for its lightweight, high conductivity, and corrosion resistance. It's commonly used in electrical applications, construction, and packaging. Other types of wire, such as copper wire, have different properties. Copper, for instance, has higher conductivity than aluminum but is heavier and more expensive. Steel wire is stronger and more durable but less conductive and prone to rust. The choice between aluminum coil and other wires depends on the specific requirements of strength, conductivity, cost, and environmental resistance for the application in question.</p>

- Q: When the aluminum roll is rolled 0.14, when the coil is taken off, what happened to the loose layer?

- in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils play a crucial role in enhancing energy-efficient insulation in various ways. Firstly, aluminum is an excellent conductor of heat, meaning it can effectively transfer heat away from the source, reducing the amount of heat that penetrates into the insulated space. This property helps to maintain a stable and comfortable indoor environment while minimizing the need for excessive heating or cooling. Additionally, aluminum coils are often utilized in the construction of air conditioning and refrigeration systems, where they act as the heat transfer medium. By efficiently absorbing and dissipating heat, these coils enable the system to cool down the air more rapidly, thus reducing energy consumption and enhancing overall energy efficiency. Moreover, aluminum is a lightweight material, which makes it easier to handle and install in insulation systems. This lightweight characteristic allows for more flexibility and ease of transportation during the manufacturing and installation processes, resulting in cost and energy savings. Furthermore, aluminum coils are highly corrosion-resistant, ensuring their longevity and preventing the degradation of insulation performance over time. This durability translates into long-term energy efficiency, as the insulation system remains effective for an extended period without requiring frequent maintenance or replacement. In summary, aluminum coils contribute to energy-efficient insulation by efficiently conducting heat, facilitating rapid cooling in air conditioning systems, reducing energy consumption, being lightweight and easy to handle, and providing long-lasting performance due to their corrosion resistance. These characteristics make aluminum coils a favorable choice for enhancing energy efficiency in insulation applications.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³). The specific gravity of aluminum coils is approximately 2.7.

Send your message to us

Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords