High Quality Wholesale Roll Aluminum Coil Cap Lid

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

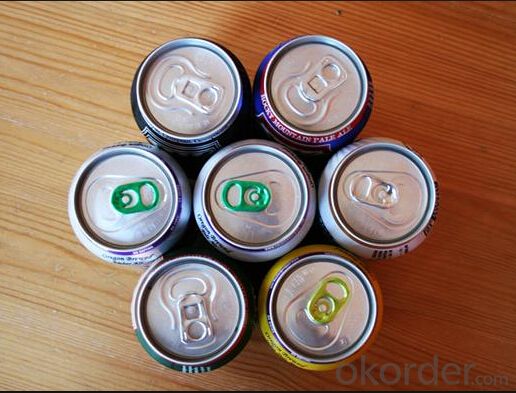

1.Structure of Aluminum Cap Lid Description:

5182 Aluminium coil can be used for aluminum can which is a container for packaging made primarily of aluminum (BrE aluminium).It is commonly used for foods and beverages but also for products such as oil, chemicals, and

other liquids.Most aluminum cans are made of two pieces. The bottom and body are "drawn" or "drawn and ironed" from a flat plate or shallow cup. After filling, the can "end" is sealed onto the top of the can. Aluminum cans are often made with recycled aluminum; approximately 68% of a standard North

American can is recycled aluminum.

2.Main Features of the Aluminum Cap Lid:

1)light weight

2)easily and economically recycled

3)superior barrier qualities

4)good formability

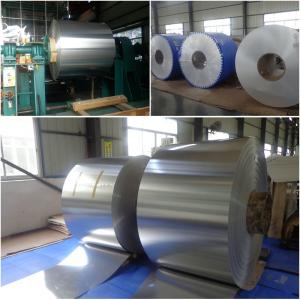

3.Aluminum Cap Lid Image:

4. Aluminium Can Lid Specification:

Alloy | Temper | Thickness | Width | Prepainting |

A5052,A5182 | H19,H18,H16(H49,H48,H46) | 0.23~0.60mm | <1550mm< span=""> | EPOXY, PPG |

Inner Diameter | Outside Diameter | MOQ | Application | Coil Weight |

405,505,605mm | <1500mm< span=""> | 10 MT | Can Cover/Tab | <5 |

5.FAQ:

1) How about your quality?

Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

2) How about the delievery time?

About 30-45 days

3) What is your payment terms?

TT or LC

- Q: How do aluminum coils contribute to lightweight transportation?

- Aluminum coils contribute to lightweight transportation by providing a lighter alternative to traditional materials like steel. Due to its low density and high strength-to-weight ratio, aluminum is used to manufacture various components in transportation vehicles, including coils for heating and cooling systems. The use of aluminum coils reduces the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions.

- Q: Are aluminum coils suitable for architectural applications?

- Yes, aluminum coils are commonly used in architectural applications due to their durability, lightweight nature, corrosion resistance, and versatility in design options. They are often used in roofing, siding, facades, and other architectural elements, offering a long-lasting and aesthetically pleasing solution.

- Q: Is aluminum veneer the same as color coated aluminum coil?

- Aluminum veneer is processed aluminum sheet, while color coated aluminum coil is raw material with color which can be called aluminum veneer after process.

- Q: What is color aluminum coil?

- The base plates are all aluminum, but the surface has been colored.

- Q: Just want to know for any boat builders out there. I have been told by my local paddling store that there are no aluminum kayaks. Why couldn't i build one? it cant be weight, I would build the frame from 1/2 inch square aluminum tubing and the body out of 1/32 high grade sheeting. So why does something like this not exist?

- There okorder

- Q: How do aluminum coils contribute to the corrosion resistance of marine applications?

- The corrosion resistance of marine applications is greatly improved by aluminum coils, thanks to the unique properties and characteristics of aluminum as a material. To begin with, aluminum naturally forms an oxide layer on its surface when it comes into contact with air. This oxide layer is highly resistant to corrosion and acts as a protective barrier to prevent further oxidation and corrosion of the metal. This inherent property of aluminum makes it an excellent choice for marine applications, where constant exposure to saltwater and moisture can be extremely corrosive. In addition, aluminum coils can be alloyed with elements like magnesium and manganese to further enhance their corrosion resistance. These alloying elements not only strengthen the aluminum but also improve its resistance to pitting and crevice corrosion. Pitting corrosion occurs when localized damage exposes the underlying metal, while crevice corrosion occurs in areas with restricted oxygen flow, such as gaps or joints. By alloying aluminum, the coils become more resistant to these types of corrosion, making them highly suitable for marine environments. Furthermore, aluminum coils can be coated with protective finishes such as anodizing or painting, which provide an extra layer of defense against corrosion. Anodizing involves creating a thicker and more durable oxide layer on the aluminum surface, thereby increasing its resistance to corrosion. On the other hand, painting acts as a physical barrier that shields the coils from direct contact with corrosive elements present in the marine environment. In conclusion, aluminum coils contribute to the corrosion resistance of marine applications through the presence of a natural oxide layer, alloying with other elements, and the option of protective finishes. These characteristics ensure that aluminum coils are highly durable and capable of withstanding the challenging conditions encountered in marine environments, guaranteeing their longevity and reliability.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q: Can aluminum coils be used in electrical wiring applications?

- Indeed, aluminum coils possess the capability to be employed in electrical wiring applications. For numerous years, aluminum has served as a conductor in electrical wiring, particularly in residential and commercial structures. As a lightweight and economical substitute for copper, it has been widely embraced. Aluminum coils find common usage in power distribution, transformers, and motors. Nevertheless, it is crucial to acknowledge that aluminum exhibits contrasting electrical and mechanical properties in comparison to copper. As a result, meticulous installation techniques and connectors exclusively crafted for aluminum wiring must be employed to guarantee both safety and efficiency.

- Q: This question asks for the distinctions between aluminum coil and steel coil, focusing on their properties and uses.

- <p>Aluminum coil and steel coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good thermal conductivity, making it ideal for applications requiring flexibility and resistance to weathering. It's commonly used in construction, packaging, and electrical applications. Steel coil, on the other hand, is stronger and more durable, suitable for heavy-duty applications. It's often used in automotive, construction, and manufacturing due to its high strength and ability to withstand heavy loads. Steel is also magnetic, which is a property not shared by aluminum. The choice between aluminum and steel coil depends on the specific requirements of the project, such as weight, strength, and environmental resistance.</p>

Send your message to us

High Quality Wholesale Roll Aluminum Coil Cap Lid

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords