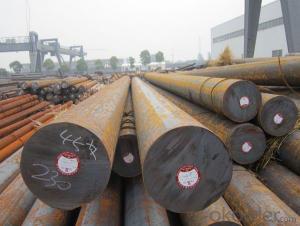

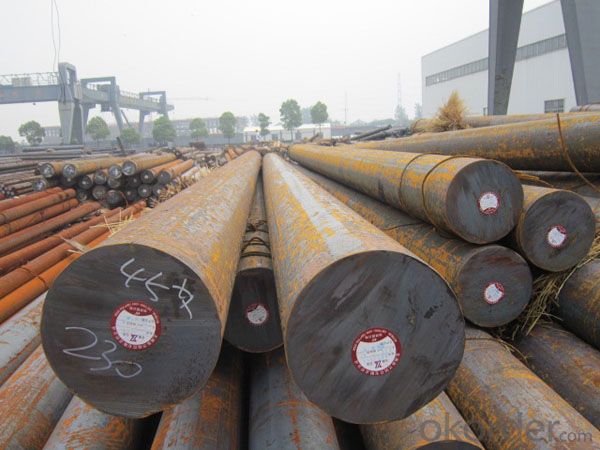

Wholesale AISI 420 Medium Carbon Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1.ISO9001:2008 certificate

2.Competive price and Best quality

3.On-time delivery

Chemical Composition(GB)%

| C | Si | Mn | Cr | P | S |

| 0.4 | 0.5 | 0.7 | 13 | ≤0.030 | ≤0.030 |

Standard

| GB | ASTM | DIN | JIS |

| 4Cr13 | 4.2 | 1.2083 | 420J2 |

Available Size

| Rolled plate | 12-120mm*720mm*6000mm | ||

| Module | 130-400mm*1000mm*6000mm | ||

Heat Treatment

| Processing | Temperature ℃ | Hardness |

| Anneal | 750-800 | ≤235HB |

| Quenching | 1050-1100 | ≥50HRC |

| Tempering | 200-300 | ≥50HRC |

Characterstics

| 1.High corrosion resistance and mirror performance | |||||

| 2.Higher strength and abrasion resistance |

Applications:Suitable for precise dies with super mirror performance and abrasion resistance,camera components,optical lens 420J2 STEEL

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different quality control measures for special steel production?

- There are several quality control measures implemented during special steel production, including rigorous inspections at various stages of the manufacturing process, such as raw material testing, chemical composition analysis, and heat treatment verification. Additionally, non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, are employed to detect any defects or inconsistencies in the steel's structure. Furthermore, dimensional and surface quality checks are performed to ensure that the final product meets the required specifications and standards.

- Q: Can special steel be used for medical applications?

- Yes, special steel can be used for medical applications. It is often used for surgical instruments, implants, and medical devices due to its high strength, corrosion resistance, and biocompatibility properties. Special steel alloys are carefully designed to meet the stringent requirements of the medical industry, ensuring safety, durability, and effectiveness in various medical procedures.

- Q: What are the specific requirements for special steel used in the textile industry?

- The primary focus when considering the specific needs of special steel used in the textile industry lies in its durability, corrosion resistance, and heat resistance. To maintain its structural integrity, the steel must withstand the harsh conditions and high temperatures involved in textile processing. Firstly, it is essential for the steel used in the textile industry to possess exceptional durability. It must be capable of enduring significant mechanical stress, such as tension, compression, and bending, without experiencing any deformation or breakage. This is crucial due to the constant movement and repetitive actions of the machinery in the textile industry. Another vital requirement is corrosion resistance. The steel must be able to resist corrosion caused by chemicals, moisture, and other environmental factors. This is particularly important as textile manufacturing processes frequently involve the use of various chemicals and water. Heat resistance is also a crucial factor to consider when selecting special steel for the textile industry. Since manufacturing processes involve high temperatures, the steel must be able to withstand and maintain its strength and properties under these conditions. This ensures the longevity and efficiency of the equipment and machinery used in textile production. Additionally, the steel used in the textile industry should exhibit excellent machinability. It should be easy to cut, shape, and form into various components and parts required for textile machinery. This allows for efficient manufacturing and customization of equipment to meet specific needs. Furthermore, the steel may also be required to meet specific standards and certifications established by regulatory bodies or industry organizations. This ensures that the steel meets the necessary quality and safety requirements. For example, it may need to comply with international standards like ISO 9001 for quality management systems. To summarize, the special steel used in the textile industry must meet requirements for durability, corrosion resistance, heat resistance, machinability, and compliance with relevant standards. Meeting these criteria ensures that the steel can withstand the demanding conditions of textile manufacturing and contribute to the efficiency and reliability of the machinery involved.

- Q: Are there any international standards for special steel?

- Special steel is subject to international standards, which are established by the International Organization for Standardization (ISO). ISO develops and publishes a variety of standards that encompass different aspects of special steel, including its composition, properties, testing methods, and quality requirements. These standards ensure that special steel manufactured by various companies and countries adheres to the same minimum quality and performance criteria. Apart from ISO, other organizations and standards bodies, such as the American Society for Testing and Materials (ASTM) and the European Committee for Iron and Steel Standardization (ECISS), also have their own specific standards for special steel. These international standards establish a unified framework for the production, trade, and utilization of special steel across diverse industries and countries, promoting consistency, reliability, and quality assurance.

- Q: What are the properties of wear-resistant stainless steel?

- Wear-resistant stainless steel possesses properties such as high hardness, excellent corrosion resistance, and good toughness. It is designed to withstand abrasion, erosion, and wear caused by friction, making it ideal for applications where durability and long-lasting performance are crucial, such as in industrial machinery, cutting tools, and automotive components.

- Q: What are the specific requirements for special steel used in the food processing industry?

- The specific requirements for special steel used in the food processing industry include being resistant to corrosion, easy to clean and sanitize, non-reactive with food products, and compliant with food safety regulations. It should also have high strength and durability to withstand heavy usage and frequent cleaning.

- Q: How does special steel contribute to reducing product downtime due to repairs?

- Special steel contributes to reducing product downtime due to repairs by offering superior strength, durability, and corrosion resistance. This type of steel is specifically designed to withstand harsh operating conditions and extreme temperatures, reducing the likelihood of breakdowns or failures. Its exceptional properties allow for longer periods between maintenance and repairs, ensuring that the product remains operational for extended periods. Additionally, special steel often enables faster and more efficient repairs, as it can be easily welded, machined, or replaced, minimizing the time required for downtime and maximizing productivity.

- Q: How does tool steel maintain its hardness at high temperatures?

- Tool steel maintains its hardness at high temperatures due to its high carbon content and the presence of alloying elements such as tungsten, molybdenum, and vanadium. These elements form carbides, which enhance the steel's ability to retain its hardness even under extreme heat. Additionally, the steel's fine grain structure and heat treatment processes contribute to its high temperature hardness retention.

- Q: How is high-speed tool steel used in the manufacturing of drills and taps?

- High-speed tool steel is used in the manufacturing of drills and taps due to its excellent hardness, wear resistance, and heat resistance properties. These qualities enable the drills and taps to cut through tough materials, such as metal or wood, with precision and efficiency. Additionally, high-speed tool steel retains its cutting edge for a longer period, reducing the need for frequent re-sharpening or replacement. This makes it an ideal material choice for producing durable and high-performance drills and taps used in various industrial applications.

- Q: What are the properties of high-strength steel?

- High-strength steel has several key properties that make it desirable for various applications. It possesses exceptional strength, allowing it to withstand heavy loads and resist deformation under stress. It also exhibits excellent toughness, meaning it can absorb energy without fracturing. Additionally, high-strength steel typically offers high hardness, good wear resistance, and enhanced corrosion resistance. Its properties make it ideal for use in industries such as automotive, aerospace, construction, and manufacturing, where durability and reliability are crucial.

Send your message to us

Wholesale AISI 420 Medium Carbon Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords