Alloy Steel AISI 5120 SCr420H

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 5120 Alloy Steel SCr420H

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition

| C | Si | Mn | Cr | S | P | Ni | Cu |

| 0.18~0.24 | 0.17~0.37 | 0.50~0.80 | 0.70~1.00 | ≤0.035 | ≤0.035 | ≤0.030 | ≤0.030 |

Products Show

Product Overviews

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, Mild steel shaft,ms bar | |

Material | ASTM | 1005, 1006, 1008, 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1055, 1060, 1065, 1070, 1080, 1084, 1016, 1022 |

DIN | Ck10, Ck15, Ck22, Ck25, Ck30, Ck35, Ck40,Ck45, Ck50, 30Mn4, 40Mn4 | |

BS | 040A04, 095M15, 045M10, 080A40, 045M10, 080M50 | |

JIS | S09CK, S9CK, S10C, S15C, S20C, S25C, S30C, S35C, S40C, S45C, S50C, S55C, S58C, SB45, S30C, S40C, S45C, S53C | |

Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| Section shape | Round, square, hexagonal, flat, angle | |

| Surface | Black painted, galvanized | |

Specifications | Round bar | Diameter: 4mm~1200mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width: 10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

Length | 2m, 4m, 5.8m, 6m, 11.8m, 12m or as required. | |

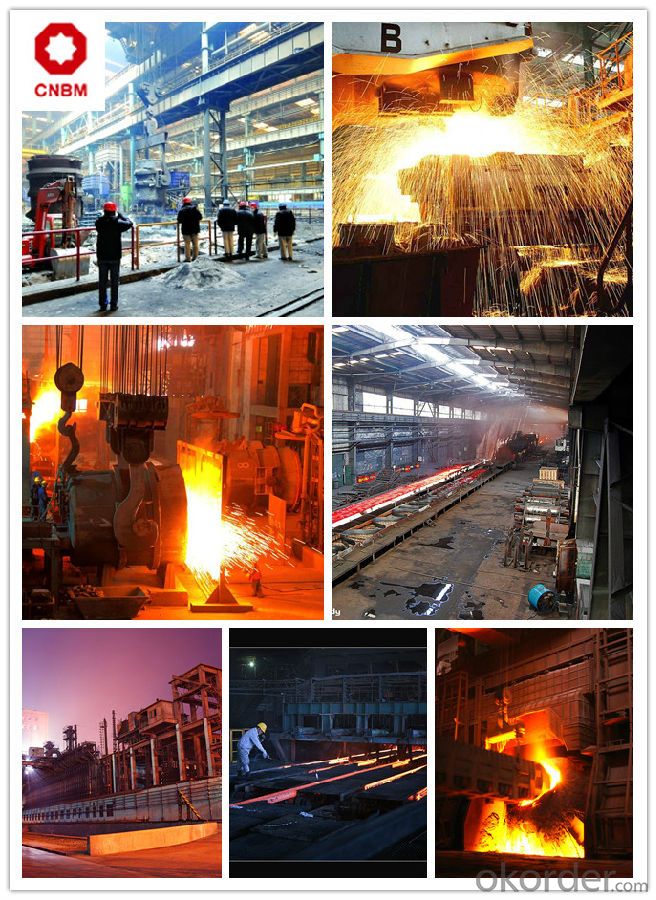

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the advantages of using nickel-chromium-aluminum alloy steel round bars?

- There are several advantages of using nickel-chromium-aluminum alloy steel round bars. Firstly, this alloy steel offers excellent corrosion resistance, making it ideal for applications in harsh environments or industries where corrosion is a concern. This resistance to corrosion helps extend the lifespan of the round bars, reducing maintenance and replacement costs. Secondly, nickel-chromium-aluminum alloy steel round bars have high strength and durability. This makes them suitable for applications that require heavy loads or need to withstand high temperatures. Their strength also allows for increased structural stability, making them a reliable choice for various construction projects or industrial applications. Additionally, this alloy steel has excellent thermal stability, meaning it can maintain its shape and mechanical properties even at elevated temperatures. This makes it particularly useful in industries such as aerospace, automotive, and power generation, where high temperatures are common. Moreover, nickel-chromium-aluminum alloy steel round bars exhibit good formability and machinability, allowing for easy fabrication and customization. This makes them versatile and adaptable for various manufacturing processes, enabling the production of complex shapes and designs. Lastly, this alloy steel is known for its resistance to oxidation and scaling at high temperatures. This characteristic makes it suitable for applications that involve exposure to extreme heat or rapid temperature changes, such as in furnaces or heat exchangers. In summary, the advantages of using nickel-chromium-aluminum alloy steel round bars include excellent corrosion resistance, high strength and durability, thermal stability, formability, and resistance to oxidation. These qualities make it a preferred choice for a wide range of industries, ensuring reliable performance and longevity in various applications.

- Q: What are the different types of steel round bars used in the automotive aftermarket?

- In the automotive aftermarket, there is a wide variety of steel round bars used. Some commonly seen types include: 1. Carbon Steel Round Bars: Due to its exceptional strength and durability, carbon steel is widely employed in the automotive industry. It finds its application in heavy-duty performance areas like suspension components, drive shafts, and steering linkages. 2. Alloy Steel Round Bars: Alloy steel, which is steel combined with other elements to enhance its mechanical properties, is prevalent in the automotive aftermarket. Applications requiring high strength, such as crankshafts, camshafts, and axles, commonly use alloy steel. 3. Stainless Steel Round Bars: Noted for its resistance to corrosion and attractive appearance, stainless steel is often preferred for automotive aftermarket applications in harsh environments. Exhaust systems, trim components, and decorative elements are examples that benefit from stainless steel's resistance. 4. Tool Steel Round Bars: Tool steel, a specialized high-carbon steel, is designed specifically for tooling and machining applications. In the automotive aftermarket, it is widely used for manufacturing specialized tools, dies, and molds. 5. Bearing Steel Round Bars: Bearing steel, another type of high-carbon steel, is tailored for bearing applications. In the automotive aftermarket, bearing steel is commonly utilized for manufacturing bearings and other rotating components. These examples represent just a small sample of the steel round bars found in the automotive aftermarket. The choice of steel for each specific application will depend on factors such as desired strength, durability, and resistance to corrosion.

- Q: What are the different cutting methods for steel round bars?

- There are several different cutting methods that can be used for steel round bars, depending on the specific requirements and equipment available. Some of the most common cutting methods include: 1. Sawing: This is one of the most basic and traditional methods of cutting steel round bars. It involves using a saw blade with teeth to cut through the metal. Sawing can be done manually with a hacksaw or powered by using a bandsaw or circular saw. It is a versatile method that can be used for both small-scale and large-scale cutting projects. 2. Shearing: Shearing is another common method of cutting steel round bars. It involves using a shear machine or hydraulic press to apply a high amount of force to cut the metal. This method is often used for cutting thick or heavy-duty steel bars. 3. Abrasive cutting: Abrasive cutting involves the use of an abrasive wheel or disc to grind away the metal and create a cut. This method is commonly used for cutting steel round bars with irregular shapes or for precision cutting projects. It can be done manually with a handheld grinder or using a machine like an abrasive cut-off saw. 4. Flame cutting: Flame cutting, also known as oxy-fuel cutting, uses a combination of oxygen and a fuel gas (such as acetylene or propane) to create a high-temperature flame that melts and cuts through the steel. This method is often used for cutting thick steel bars or for shaping metal. 5. Plasma cutting: Plasma cutting is a more advanced method that uses a plasma torch to cut through the steel. The plasma torch generates a high-velocity jet of ionized gas that melts and removes the metal. This method is commonly used for precision cutting, as it allows for greater control and produces cleaner cuts compared to other methods. It is important to note that the choice of cutting method will depend on factors such as the thickness and hardness of the steel round bar, the desired precision of the cut, and the available equipment and resources. It is recommended to consult with a professional or experienced metalworker to determine the most appropriate cutting method for a specific project.

- Q: How are steel round bars stored and transported?

- Steel round bars are typically stored in warehouses or storage facilities. They are often stacked horizontally on racks or placed in designated storage areas. To prevent damage and ensure easy accessibility, bars of different sizes or grades are segregated and labeled accordingly. When it comes to transportation, steel round bars are commonly loaded onto flatbed trucks or shipping containers, depending on the quantity and distance of the shipment. To prevent movement and potential damage during transit, bars are secured using straps or other fastening methods. Additionally, protective coatings or wrapping materials may be applied to safeguard against corrosion or moisture. Overall, proper storage and transportation practices are crucial to maintain the quality and integrity of steel round bars.

- Q: Are steel round bars suitable for high-stress applications?

- Yes, steel round bars are suitable for high-stress applications. Steel is known for its strength and durability, making it an ideal material for high-stress environments. Round bars, in particular, offer excellent tensile strength and can withstand heavy loads and intense pressure. They are commonly used in industries such as construction, manufacturing, and engineering, where high-stress applications require a reliable and robust material. The round shape of the bars also provides uniformity in strength, ensuring consistent performance under extreme conditions. Additionally, steel round bars can be heat-treated to further enhance their mechanical properties, making them even more suitable for high-stress applications. Overall, steel round bars are a reliable and effective choice for demanding environments that require exceptional strength and resilience.

- Q: Can steel round bars be used for making springs?

- Yes, steel round bars can be used for making springs. Steel is a widely used material for springs due to its high strength and durability. Steel round bars can be shaped into various types of springs, including compression springs, extension springs, and torsion springs. The round bar can be cut to the desired length and then heat-treated to achieve the desired hardness and springiness. The specific type of steel and the heat treatment process will determine the spring's characteristics, such as its load-bearing capacity, flexibility, and resistance to fatigue. However, it is important to note that the design and engineering of springs require careful consideration of factors such as the required spring rate, maximum load, and operating conditions to ensure the optimal performance of the spring.

- Q: Are steel round bars resistant to chemicals or acids?

- Yes, steel round bars are generally resistant to chemicals and acids due to their high corrosion resistance properties. However, the level of resistance may vary depending on the specific type of steel and the concentration and temperature of the chemicals or acids involved.

- Q: What are the different types of steel round bar surface treatments used in the aerospace industry?

- In the aerospace industry, there are several types of steel round bar surface treatments that are commonly used to enhance the performance and durability of the materials. These treatments are specifically designed to meet the stringent requirements and standards set by the industry. Some of the different types of steel round bar surface treatments used in the aerospace industry include: 1. Passivation: This treatment involves the removal of iron particles and other contaminants from the surface of the steel round bar. It helps to prevent corrosion and improves the overall corrosion resistance properties of the material. 2. Shot Peening: Shot peening is a process that involves bombarding the surface of the steel round bar with small metallic shots. This treatment induces compressive stress on the surface, which enhances the material's fatigue strength and resistance to stress corrosion cracking. 3. Electroplating: Electroplating is a common surface treatment used in the aerospace industry. It involves the deposition of a layer of metallic coating onto the steel round bar through an electrochemical process. This treatment enhances the material's corrosion resistance, wear resistance, and aesthetic appearance. 4. Anodizing: Anodizing is an electrolytic passivation process that is commonly used on aluminum alloys. However, it can also be used on steel round bars. This treatment forms a thick, durable, and corrosion-resistant layer of oxide on the surface, which improves the material's resistance to wear, corrosion, and scratching. 5. Nitriding: Nitriding is a surface hardening treatment that involves the diffusion of nitrogen into the surface of the steel round bar. This treatment improves the material's surface hardness, wear resistance, and fatigue strength. 6. Chemical Conversion Coating: Chemical conversion coating is a treatment that involves the formation of a thin, protective layer on the surface of the steel round bar. This coating enhances the material's corrosion resistance and provides a good base for subsequent paint or coating applications. These are just a few examples of the different types of steel round bar surface treatments used in the aerospace industry. Each treatment offers unique benefits and is selected based on the specific requirements of the application, such as corrosion resistance, wear resistance, fatigue strength, and aesthetic appearance.

- Q: Can steel round bars be painted or coated?

- Yes, steel round bars can be painted or coated. Painting or coating steel round bars is a common practice to enhance their appearance, protect them from corrosion, and provide additional functionality. The process typically involves cleaning the surface of the bars to remove any dirt, grease, or rust, and then applying a primer or base coat followed by a topcoat or finish. The type of paint or coating used will depend on the specific requirements of the application, such as the desired color, level of protection, or resistance to environmental conditions. Additionally, certain coatings can provide specific properties like anti-slip, heat resistance, or chemical resistance. Overall, painting or coating steel round bars is an effective way to improve their aesthetics and durability.

- Q: Can steel round bars be used in the fabrication of machinery?

- Yes, steel round bars can definitely be used in the fabrication of machinery. Steel round bars are commonly used in the manufacturing industry for various applications, including the fabrication of machinery and equipment. They possess several desirable properties that make them suitable for this purpose. Firstly, steel round bars offer excellent strength and durability. They are known for their high tensile strength, which means they can withstand heavy loads and resist deformation. This strength is crucial in machinery fabrication, as the components of machinery need to be able to endure the stresses and forces that they will be subjected to during operation. Additionally, steel round bars have good machinability, which means they can be easily shaped and formed into the desired components for machinery. This makes them highly versatile and allows for the creation of complex and intricate machine parts. Furthermore, steel round bars have good resistance to corrosion and wear, which is essential in machinery fabrication. Machinery often operates in harsh environments or comes into contact with various substances, such as chemicals, oils, or abrasive materials. The corrosion and wear resistance of steel round bars ensure that the fabricated machinery can withstand these conditions and maintain its performance over time. Lastly, steel round bars are readily available and cost-effective. They can be easily sourced from suppliers and manufacturers, making them a practical and economical choice for machinery fabrication. Overall, steel round bars are a popular and reliable material for the fabrication of machinery. Their strength, machinability, resistance to corrosion and wear, and availability make them an ideal choice for creating durable and high-performing machine components.

Send your message to us

Alloy Steel AISI 5120 SCr420H

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords