White Food Grade PU Conveyor Belt Smooth PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Food Grade PU Conveyor Belt Smooth PVC Conveyor Belt

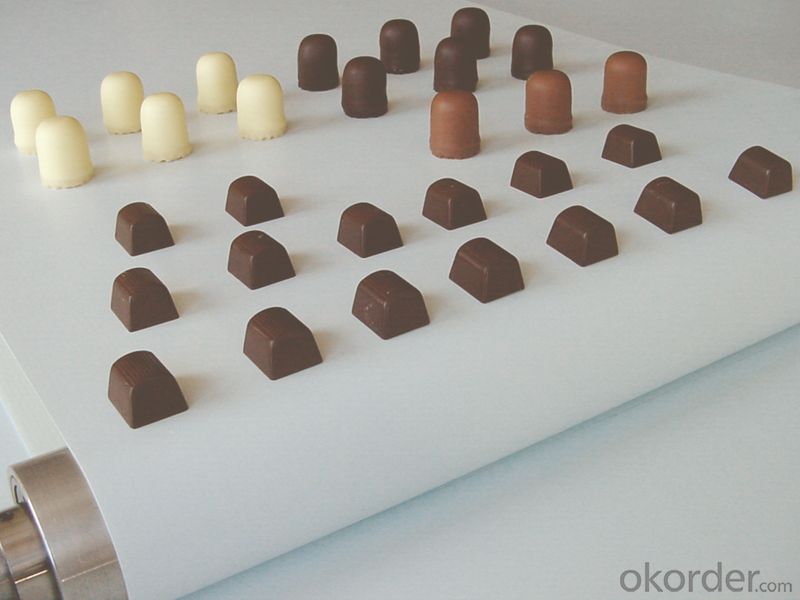

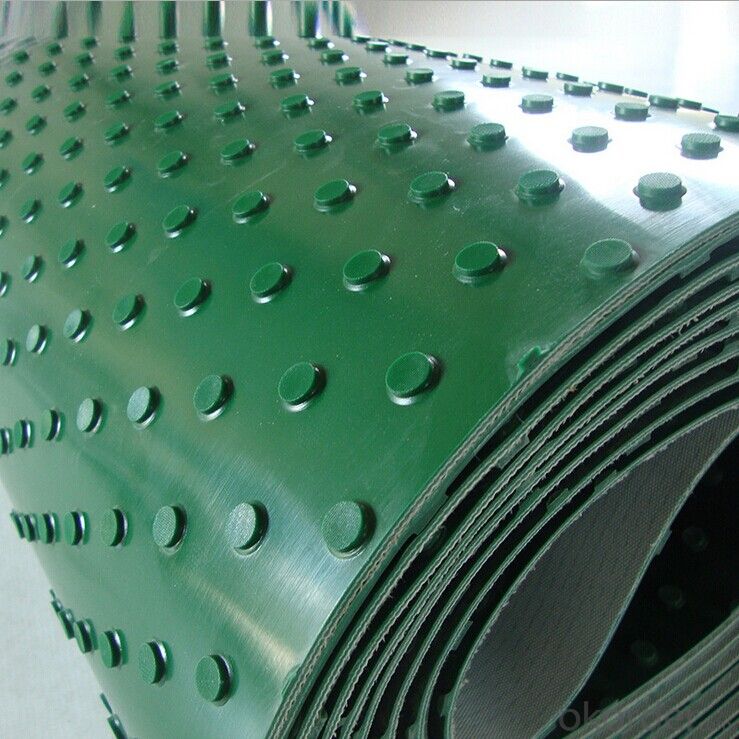

Descriptions of White PVC PU Conveyor Belt

PVC conveyor belt in flexible construction provides high strength,low stretch characteristics, dimensional stability & are totally resistance to moisture, rot & mildew.

PVC Conveyor belt uses polyester fabrics as reinforcing materials, mainly used for conveying light, medium quality materials, suitable for use on the conveyor systems.

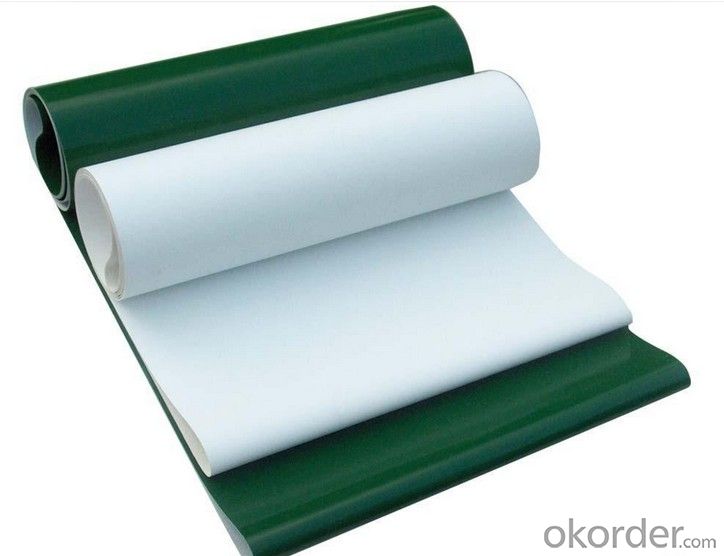

Hygienic Conveyor Belt is manufactured in both white, transparent & blue provide excellent oil & greaseresistance. Our hygienic food belt range is available with varioustop & bottom cover finishes & hardness. Multiply Hygienic PVC& PU Conveyor Belts are available with either high gloss smooth PVC/PU, PVC/PU cover or bare polyester top covers.

Features of White PVC PU Conveyor Belt

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Application areas of White PVC PU Conveyor Belt

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

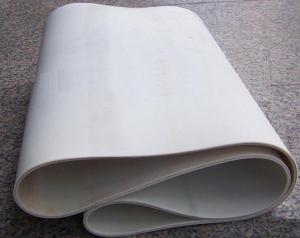

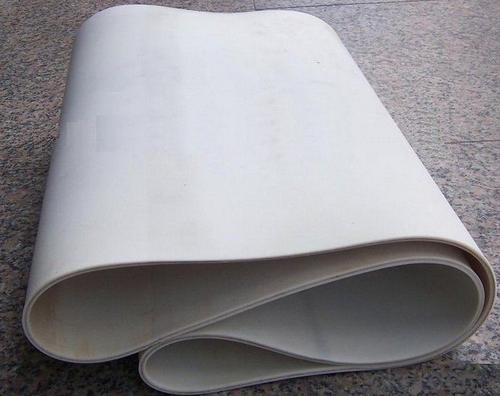

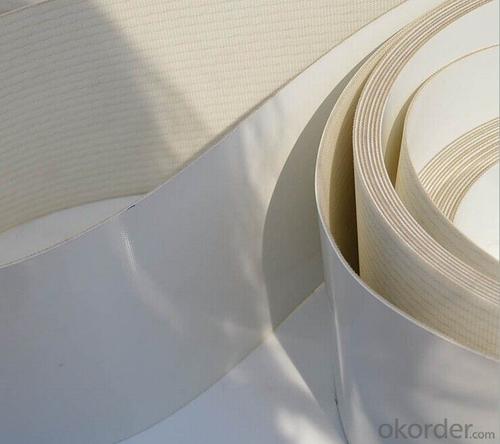

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What solvent is used to clear the melted rubber layer?

- The acetone extractives are some fatty acids and steroids, some natural antioxidants and accelerators, and can help with the powdery agent in the process of mixing and dispersion of rubber softening effect.Ash containing mainly magnesium phosphate and calcium phosphate salts, copper, manganese, iron and other metal compounds is very small, because these valence metal ion can promote the aging of rubber, so their content should be controlled.

- Q: How should the rubber products be dirty?

- First coated with vinegar on the top, after dry, and then wipe paper, so clean

- Q: What are the uses of rubber oil?

- The so-called "rubber oil" is only a generic term, in different places of use, there are different titles. In synthetic rubber plants, in order to improve some properties of rubber, it is necessary to charge mineral oil to synthetic rubber, which is called rubber filling oil. For rubber products factory, downstream enterprises produce all kinds of rubber products, they tend to be rubber oil called rubber processing oil, rubber processing oil, rubber softener and so on. Whatever we call them, we can call them rubber oil, or rubber oil.

- Q: What are the common rubber products, please tell me

- Rubber products mainly include tires, sidewall, rubber strips and inner tubes, as well as parts of automobiles. They are made of wires, cables, wrapping and high voltage and extra high voltage insulating materials. They can also make rubber shoes and guardOther light colored products, such as raw materials, and other general industrial rubber products, cushioning materials, conveyor belts and belts, oil resistant hoses, gaskets, and chemical resistanceCorrosion equipment lining.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q: High strength rubber repairing agent

- The operation time, generally require the hole position Polish cleaning after the rubber putty filled in the damaged parts, and then use the scraper scraping smooth, repair parts and guarantee the smoothness can be part of the belt.

- Q: Advantages and disadvantages of rubber products

- Styrene butadiene rubber SBR(Styrene Butadiene Copolymer) and butadiene styrene copolymers, compared with natural rubber of uniform quality, less foreign body, has better wear resistance and aging resistance, but the mechanical strength is weak, can be combined with natural rubber mixing. Non - oily material advantages: low cost, good water resistance, hardness below 70 with good elasticity, high hardness with poor shortcomings: compression, does not recommend the use of ozone, acid, oil, oil and fat ester and most hydrocarbons. Widely used in tire industry, shoes, cloth and conveyor belt industry etc..

- Q: How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

- Q: How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

Send your message to us

White Food Grade PU Conveyor Belt Smooth PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords