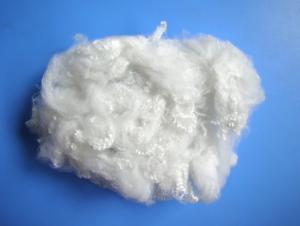

Polyester Staple Fiber,1.2D-18D available

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Polyester Fiber

Fiber Length: 32mm-102mm

Fineness: 1.2D-18D

Package of Polyester Staple Fiber:

Bales package around 260KG. About 40 bales are put info 1x20'GP while 75 bales are put info 1x40'HQ. And the loading quantity is allowing flutuation.

Application of Polyester Staple Fiber:

Polyester Staple Fiber is widely used for spinning, nonwoven, carpet, textile, automotive interior etc.

.FAQ

Here is several common questions we prepared which may help you to know us well:

1>Introduction of the company?

we focus on the production of PET staple fiber,. have been exporting this product to overseas market for many years. Customized product is also available based on your detailed requirements.

2> Is customized product available?

Yes, different specification could be made as per your kind request.

3>What's minium order quantity and can we have a container of several different specifications?

Normally we suggest you a full container load as moq as the price would be the best with full container. Of course , several specification for one container is ok if each specification is availbale.

- Q: What are the differences between automotive carbon fiber stickers and films? Who knows the industry, please point out!

- The so-called carbon fibre seems many: some of the name of 3M foundry (not to disclose the name), Belgium (a company, respect gelatinous Caidie agent, the price is a bit high, Mike should also stick).Butterflies and Mike stick is in Belgium, tariffs to the hands of consumers at least more than 200 / square meters.

- Q: Which material is good, cotton blended or synthetic?

- From the material, cotton (natural fiber best), blending, followed by the poor purification of fiber.But there are a variety of fabric style and function of all kinds of fabrics, from dress up, suggest or with cotton and other natural fiber, natural fiber from the nature, with good skin, comfortable; chemical fiber fabrics from raw materials are synthetic, wearing skin, sweat less, but wear solid, etc., can be processed to form many kinds of clothes.

- Q: What is blended spinning fabric?

- For example, polyester cotton blended fabric is made of polyester fiber, which is made of 65%-67% polyester and 33%-35% cotton blended yarn.

- Q: Which kind of air conditioner is acetate fiber and polyester fiber?

- Polyester fiber, which is commonly known as polyester fiber, is the most common synthetic fiber, moisture absorption is not very good, easy to generate static electricity. But its application is very extensive, can make countless kinds of different types of fabrics, and there are countless different uses, the price is cheaper. But it can not be said that it is not good, there are many areas of vinegar fiber can not do.

- Q: Polyester fiber clothes pilling how to do? How can you clean up after never pilling?

- Polyester suede fabric can't handle pilling, which is the nature of this fiber. Clean up will, don't bother.

- Q: What material is microfiber shoe?

- The definition of superfine fiber is different, also known as micro fiber, fine denier fiber, very fine fiber, the English name microfiber. Generally, the denier 0.3 denier (diameter 5 microns) fiber below is called superfine fiber. Foreign countries have produced 0.00009 denier ultra fine wire, if such a wire pulled from the earth to the moon, its weight will not exceed 5 grams. China has been able to produce 0.13 - 0.3 denier microfiber. The main ingredients of superfine fiber polyester polyester, nylon polyemide two (which is generally 80% domestic polyester nylon 20% and polyester, 100% (water absorption effect is poor, poor hand)).

- Q: Carbon fiber bicycle, advantages and disadvantages

- Carbon fiber bicycle: frame, front fork, wheel set, mainly carbon fiber as raw material bike. Mainly medium and high grade racing bicycles.Carbon fiber not only has the inherent characteristics of carbon materials, but also has the flexibility and processability of textile fibers. It is less than 1/4 of steel, but its strength is very strong. And its corrosion resistance is outstanding, is a new generation of reinforced fiber.

- Q: What's the difference between a gold tube and a carbon fiber?

- Gold tube is also a kind of carbon fiber tube, but the gold tube is now the most top of the heating tube, heating speed, heating temperature high

- Q: Carbon nanotubes and carbon nanofibers are the same thing? What's the connection?

- Carbon nanotubes, as one-dimensional nanomaterials, are lightweight, hexagonal, and perfectly connected with many unusual mechanical, electrical, and chemical properties. In recent years, with the development of carbon nanotubes and nano materials, the broad application prospects of carbon nanotubes and nanomaterials have been emerging. Carbon nanotubes, also known as buckytubes, is a kind of special structure (radial size to the nanometer scale, shaft size of micrometer, both ends of the pipe are basically closed) one-dimensional quantum materials. Carbon nanotubes mainly consist of hexagonal carbon atoms and form coaxial tubes of several layers to tens of layers. The distance between layers is fixed, about 0.34nm, and the diameter is generally 2~20 nm. And according to the different orientations of the carbon hexagon along the axial direction, they can be divided into three types: zigzag, armchair and spiral. Among them, the spiral carbon nanotubes have chirality, while zigzag and armchair carbon nanotubes do not have chirality.

- Q: How are invisible absorbing materials made? What is the carbon fiber method?

- This question deals with cutting-edge science and technology and can only be answered in accordance with the literature you can now find.The carbon fiber represents its invisible factor, and the fiber cross-section of the carbon fiber is circular. If you want to improve the wave absorbing performance, now, can change the shape of spinneret, in the production of carbon fiber, ejected section type Y or type O filaments, processing. In this way, the electromagnetic wave is refracted and reflected repeatedly in the small fiber space so as to achieve the effect of absorbing waves. Can only speak so much, if the landlord to school, the landlord can search in the library, AC, SCI and other periodicals web site carbon fiber stealth. There are references to this, and others, you'd better ask the supervisor what. Something is inconvenient to say here.

Send your message to us

Polyester Staple Fiber,1.2D-18D available

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords