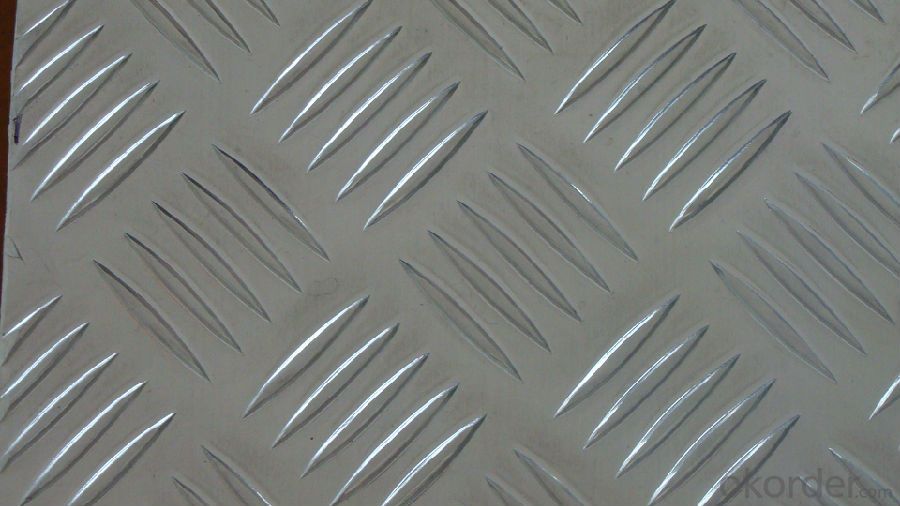

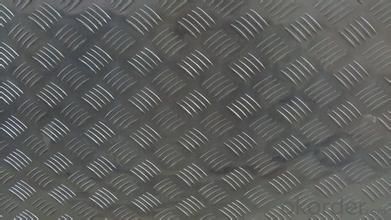

Weight of Diamond Aluminum Plate Color Anodized Aluminum Sheet Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

1.Dark green surface, color changed into light green after exposure.Image checked easily.

2.Surface Quality :be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3.Faithful reproduction capacity, result at clear images.

4.Highly durable, long impression available.

5.Excellent sensitive character.

6.Resolution : 2%-98%

7.Material:1050/1060/1070/1100/2A16/2A06/2A12/2024/3003/3A21/4A01/5052/5005/5083/5A05/6061-T6/6063-T5/6082/7021/7075-T6/8011,etc

8.Certificate: ISO9001:2000, SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO)

9.Packing:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation,wooden pallets

10.Application:Aircraft, automobile, train,Building wall, ceilings, roofing, furniture cabinet, lighting plate,etc

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for ventilation systems. Its high thermal conductivity allows for efficient heat transfer, making it ideal for applications where temperature control is necessary. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs required for ventilation systems. Overall, aluminum sheets are a popular and practical choice for manufacturing ventilation systems.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: How thick can aluminum sheets be?

- The thickness of aluminum sheets can differ depending on the specific application and requirements. Typically, aluminum sheets are obtainable in thicknesses that span from 0.008 inches (0.2 mm) to 0.25 inches (6.35 mm) or possibly even thicker for specialized industrial uses. Nevertheless, it is worth mentioning that aluminum sheets exceeding 0.25 inches are less prevalent and might necessitate custom production or special orders. Ultimately, the intended use, structural prerequisites, and the overall feasibility of the manufacturing procedure determine the thickness of an aluminum sheet.

- Q: What type of aluminum plate does it contain?

- The 3 * * * series aluminum plate is mainly composed of manganese, and the content is between 1.0-1.5%.4 * * * series aluminum sheet: stands for 4A01. The 4 * * * series aluminum plate belongs to a series with high silicon content.5 * * * series aluminum sheet: stands for 5052, 5005, 5083, 5A05 series.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: What are the different heat treatment options available for aluminum sheets?

- Aluminum sheets can undergo various heat treatment options, each imparting distinct characteristics and properties to the material. 1. Annealing: To relieve internal stresses and enhance ductility and machinability, the aluminum sheet is heated to a specific temperature and gradually cooled down. 2. Solution Heat Treatment: This treatment involves subjecting the aluminum sheet to high temperatures and swiftly cooling it in water or another cooling medium. By dissolving and homogenizing alloying elements, solution heat treatment improves strength and hardness. 3. Precipitation Hardening: Also known as age hardening, this treatment is typically performed after solution heat treatment. It entails heating the aluminum sheet at a lower temperature for a specific duration, allowing alloying elements to precipitate and form fine particles. This process enhances strength and hardness without compromising ductility. 4. Stress Relieving: To alleviate residual stresses developed during fabrication or machining, the aluminum sheet is heated to a specific temperature and gradually cooled. This reduces the risk of distortion or cracking. 5. Hardening: Achieving hardening involves heating the aluminum sheet to a specific temperature and rapidly quenching it. This process boosts strength and hardness, making the material suitable for applications requiring high strength-to-weight ratios. It is important to consider the desired properties and application requirements when selecting a heat treatment option for aluminum sheets. Seeking guidance from a metallurgical expert or referring to material specifications can aid in determining the most appropriate choice.

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum forms metallic bonds in the metal and aluminum alloys. Aluminum forms covalent bonds as with aluminum isopropoxide. Aluminum forms ionic bonds as in aluminum sulfate. Aluminum chloride is ionic in aqueous solution but molecular in solvents such as benzene.

- Q: Can the aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its lightweight nature, durability, and versatility. It can be easily molded and shaped into various forms, making it suitable for a wide range of architectural designs. Additionally, aluminum is resistant to corrosion, making it a long-lasting option for cladding. Its ability to be coated in different finishes also allows for customization to match the desired aesthetic of the building. Overall, aluminum sheets are a reliable and practical choice for architectural cladding.

- Q: What are the different methods for engraving aluminum sheets?

- There are several methods for engraving aluminum sheets, including laser engraving, rotary engraving, chemical etching, and mechanical engraving. Each method offers unique benefits and can produce high-quality results depending on the desired outcome and specific requirements.

Send your message to us

Weight of Diamond Aluminum Plate Color Anodized Aluminum Sheet Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords