Weed Barrier Fabric or Capped Woven Fabric for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

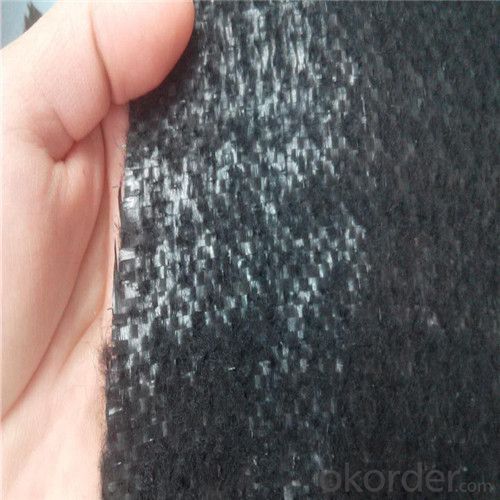

Weed Barrier Description

Weed barrier fabric is a kind of composite with woven and needle punched, made from polypropylene, and botanical component of pest control, which attempts to stop weeds, conserves soil moisture, increases growth.

Weed Barrier Fabric Specification

Weight: 120gsm-200gsm

Width:1m -6m

Length:as request

Color: white, black, green, as request

Strip: every 12", as request

Weed Barrier Fabric Property

1)UV treated

2)Under turf Chemical free

3)Effective weed control

4)Allows air, water and nutrients to reach the soil and the plant roots

5)Very resistant to puncture

6)Easy to install

7)Raises quantity and quality of crops

Weed Barrier Fabric Application

Used for Paths, Patios, Timber decking, Block paving, Soft landscaping and so on.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geotextiles be used in waste containment systems?

- Yes, geotextiles can be used in waste containment systems. Geotextiles are often employed as a barrier or filter in these systems to prevent the migration of contaminants, provide reinforcement, and enhance drainage.

- Q: Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q: The vertical permeability coefficient of 400 g per square filament geotextile is generally how much

- 1.0 × 10-1cm / sK × (10-1-10-3) I specialize in the production of geotechnical materials

- Q: are they used for same purpose with just different terminology?

- Geotextiles And Geomembranes

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production include energy consumption during manufacturing, emissions of greenhouse gases, water and air pollution from chemical processes, and the generation of solid waste. However, compared to traditional construction materials, geotextiles have lower environmental impacts in terms of resource consumption, carbon emissions, and waste generation.

- Q: How do geotextiles help in filtration of stormwater?

- Geotextiles help in filtration of stormwater by acting as a barrier that allows water to pass through while trapping sediment and pollutants. They prevent the clogging of drainage systems by retaining particles and promoting the flow of clean water, thus improving water quality and reducing the risk of flooding.

- Q: Are geotextiles resistant to biological degradation?

- Yes, geotextiles are generally resistant to biological degradation.

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems. They are installed within the geocell walls and act as a stabilizing agent by providing reinforcement and preventing soil migration. Geotextiles distribute the load evenly, increase the overall strength of the system, and improve the overall stability and longevity of the geocell structure. Additionally, geotextiles can also act as a filtration layer, allowing water to pass through while preventing soil particles from clogging the system, thereby maintaining its efficiency and functionality.

- Q: Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles can act as a barrier to prevent the spread of contaminants, while also allowing water and air to pass through. They can be used to separate clean and contaminated soils, provide stability to slopes, and enhance the effectiveness of other remediation techniques such as phytoremediation or soil vapor extraction. Additionally, geotextiles are durable and cost-effective, making them a practical choice for soil remediation projects.

- Q: Geotextile moisture-proof layer: 200 cloth +400 film +200 cloth

- You are not to composite geomembrane, I was specializing in the production of geotechnical materials, account number that phone

Send your message to us

Weed Barrier Fabric or Capped Woven Fabric for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords