PVC Conveyor Belt The Treadmill Belt Running Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt The Treadmill Belt Running Belt

1.Product Description:

Description: Customized

Weight: 1.5~2.2KG/ square meters

Tensile strength: 100~160N/mm

Minimum wheel diameter: 20~30MM

Working temperature: -10 degrees ~110 degrees

Thickness:1.4,1.6,1.8,2.0mm Etc.

The maximum width: less than 1680MM

Perimeter: according to the size of production

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

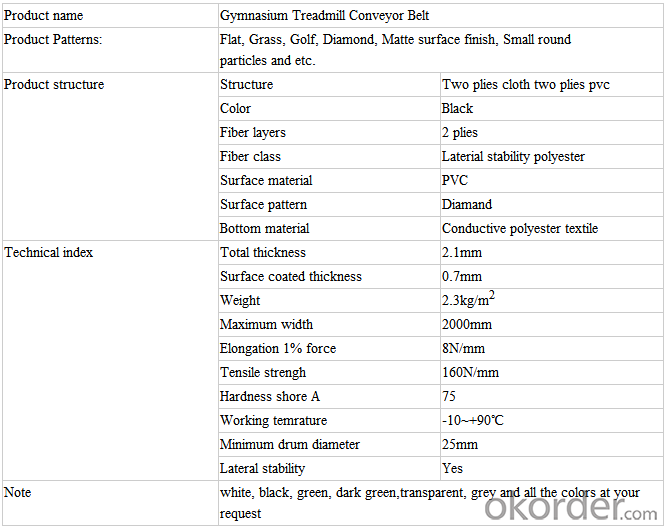

2.Product Specification:

3.Product Advantages:

1).Our treadmill conveyor belts need no lubrication and run quietly and smoothly – without noise or tracking problems.

2).Our treadmill conveyor belts combine low energy sonsuption with durability and an excellent appearance

4.Product Feature:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

5.Product Quality Control

We have very strict quality control system to test all the finished conveyor belts to ensure all the products you receivec are of high quality.

6.Packaging & Shipment

Conveyor belts are packed in rolls and covered by poly woven bags. Also, we can pack it according to your requirments.

7.Product Pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the differences in the properties of neoprene models?

- The appearance of white, yellow or light brown flakes or lumps, is chloroprene (2- chloro -1,3- butadiene) as the main raw material for the polymerization of alpha elastomer. The solubility parameter of chloroprene rubber accounts for Delta =9.2~9.41. Soluble in toluene, xylene, two ethyl chloride, three vanadium ethylene, slightly soluble in acetone, methyl ethyl ketone, ethyl acetate, insoluble in hexane, cyclohexane, Yu Zheng solvent gasoline, but soluble by appropriate proportion of good and poor solvent and non solvent or poor solvent and non solvent composition of the mixed solvent in plants oil and mineral oil and solvent swelling.

- Q: How long is the warranty period for EPDM?

- The warranty period for rubber products (EPDM) is about 1--6 months.

- Q: How can rubber and mould not be bonded when producing rubber products?

- When rubber products are made, rubber and mould can not be bonded:1, abrasives to be polished, coating treatment, to achieve the most smooth surface and high temperature corrosion resistance requirements!2, formula design, less use of sticky, easy to corrosive materials;3, curing process should meet the requirements of formula design!

- Q: What is the lowest cost material for the synthesis of rubber?

- There are many kinds of synthetic rubber. Many kinds of materials are used in synthesis, which material is lower or can not be measured

- Q: Can rubber products be injection molded and plastic injection functions?

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding. Die casting method. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: How can rubber products prevent fading?

- Light and white rubber products are prone to yellowing in the course of use and storage, thus affecting appearance and quality, resulting in various economic disputes and irreversible losses.

- Q: What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Generally used for metal strip trimming, that is, after the strip of metal strips with a fixed tool to remove burr or chamfer on both sides of the required radian,Scope of application: used in tableware, stationery, hardware, sheet metal and other special equipment industry.Main functions: grinding and polishing of double sides of roll beltApplicable materials: stainless steel, copper strip, aluminum belt and other metal coil.It has the advantages of rough grinding, fine grinding and polishing. It is suitable for grinding the bevel and straight edges of metal belts of different sizes and thicknesses, and is equipped with grinding wheels and spare grinding wheels. The grinding wheel has the advantages of long service life, regular forming rules and high efficiency.

- Q: What do you pay attention to when using rubber?

- The greater the polarity of the rubber, the better the bonding effect. Among them, nitrile butadiene chloroprene rubber is of great polarity and strong adhesive strength. Natural rubber, silicone rubber and isobutyl rubber have less polarity and weak cohesive force. In addition, the rubber surface often has the release agent or other free out auxiliaries, hinders the adhesive effect.Adhesive is used to connect rubber, and the concrete methods are divided into hot sticking method and cold sticking method.Hot sticking method is realized by adhesive plastication of unvulcanized rubber and glued rubber together after curing, the method is complicated, need to heating and pressurizing equipment, inconvenient to use.Cold adhesive method is to apply the adhesive to the surface of the glued product. After airing, fold it and solidify it at room temperature. Of course, proper heating can shorten the curing time and increase the bonding strength. Cold sticking method is simple and energy saving. It is a good method to be popularized.

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber is a kind of polymer material made of petroleum and natural gas as raw material and polymerized with diene and olefin as monomers.The main purpose of the industrial synthesis of rubber material is cost saving, improving the properties of rubber products, because the natural rubber products price is more expensive, in order to reduce the cost of enterprises have invested a lot of synthetic rubber materials with low cost.

- Q: How to solve the spray of rubber products?

- For the problem of rubber surface frost spray, Siyuan shoe material company targeted to develop the corresponding treatment agent productionProduct: SY-210C series of rubber, cream, spit and yellow treatment agent, can clean and keep the original surface of rubber products thoroughlyIn two, secondary processing products, but also increase the surface adhesion of the adhesive joint.

Send your message to us

PVC Conveyor Belt The Treadmill Belt Running Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords